5motor control & motor settings – Lenze i700 User Manual

Page 102

5

Motor control & motor settings

5.10

Synchronous motor (SM): Pole position identification

102

Lenze · i700 servo inverter · Reference manual · DMS 1.5 EN · 03/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.10.4

Pole position identification PPI (without movement)

This function extension is available from version 01.03!

Functional description

After controller enable, a defined pulse pattern is output which provides currents up to

approximately maximum motor current. The respective currents are measured. Based on these

currents, the field distribution can be detected so that the pole position can be calculated.

Afterwards, the controller is inhibited automatically.

The pole position identification (without movement) does not require any further

parameterisation.

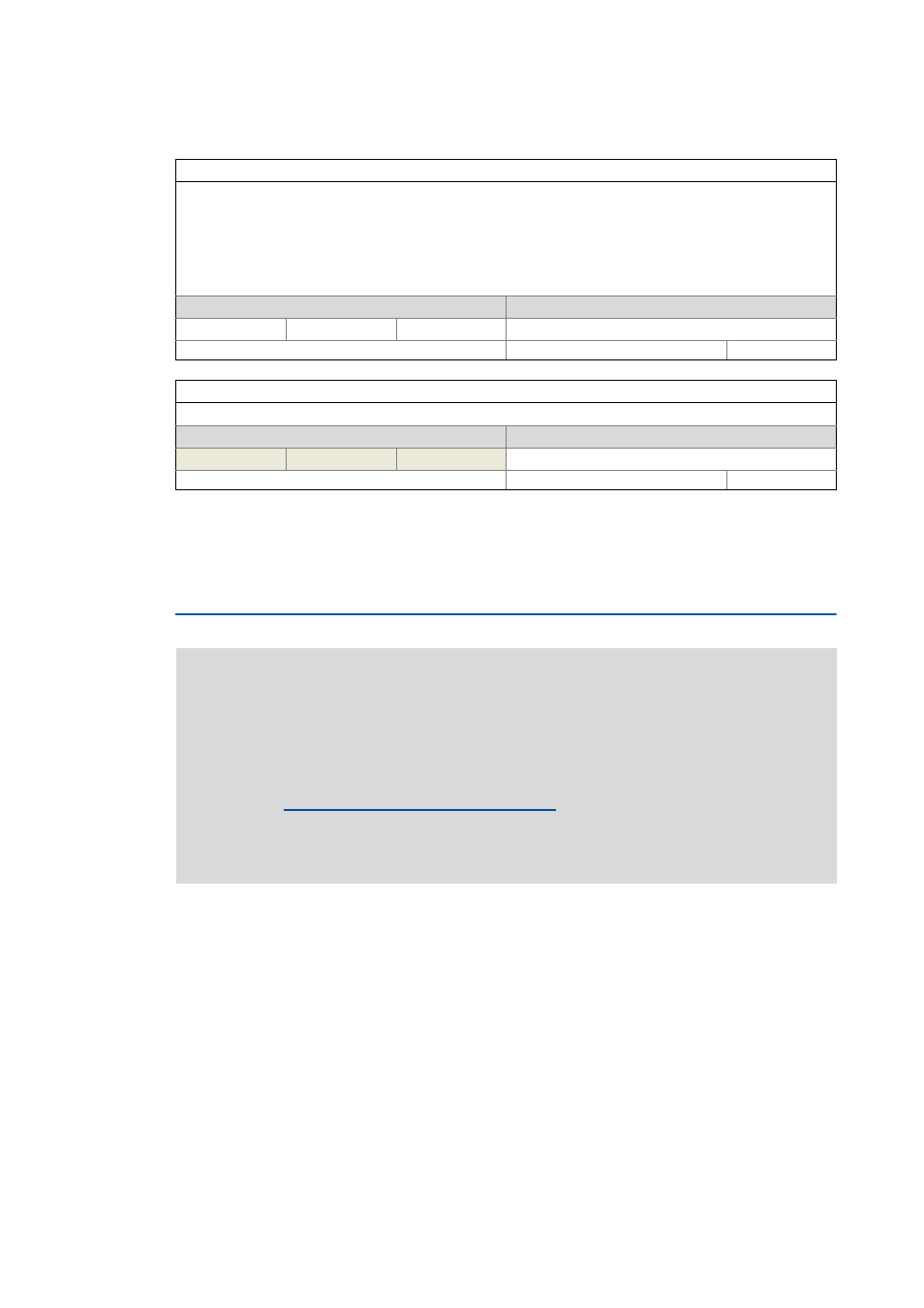

Subindex 5:

PPI (min. movement): Max. move permitted

Adjustment of the permitted movement

• The pole position identification comprises a monitoring function for the follow-up control. If a movement

greater than the permissible movement set is detected by the encoder system, the pole position identification is

aborted and the error response parameterised is tripped:

• In order to detect a non-permissible blocking of the machine, a positive and negative test angle relative to the

current position are defined after the identification. The machine must align itself to these two test angles

within a tolerance of 25 %. The size of the test angle corresponds to the max. move permitted set here.

Setting range

(min. value | unit | max. value)

Lenze setting

1

°

90 20 °

Write access CINH OSC P RX TX

UNSIGNED_8

Subindex 6:

PPI (min. movement): Absolute current amplitude

Display of the absolute current amplitude

Display area

(min. value | unit | max. value)

Initialisation

0.00

A

42949672.95

Write access CINH OSC P RX TX

Scaling: 1/100

UNSIGNED_32

Note!

Due to a slight inaccuracy in this PLI process, higher variations regarding the detected

pole position have to be expected. This also causes different torque efficiencies. Thus, we

recommend the use of higher-order PLI processes ("360 °" or "min. movement"). If this is

not possible for process reasons, we recommend the execution of the pole position

identification PLI (without movement) only after the controller is enabled for the first

time.

Optional settings (starting performance)

During the pole position identification, the error 0xFF13 ("identification cancelled") may

occur. This may be an indication that the motor features are not suitable for this PLI

process.