Commissioning – Lenze ECSCPxxx User Manual

Page 221

Commissioning

Configuring the electrical shaft ("E−Shaft")

Electrical shaft via MotionBus (CAN) with PLC as electrical shaft master

l

221

EDBCSXP064 EN 8.0

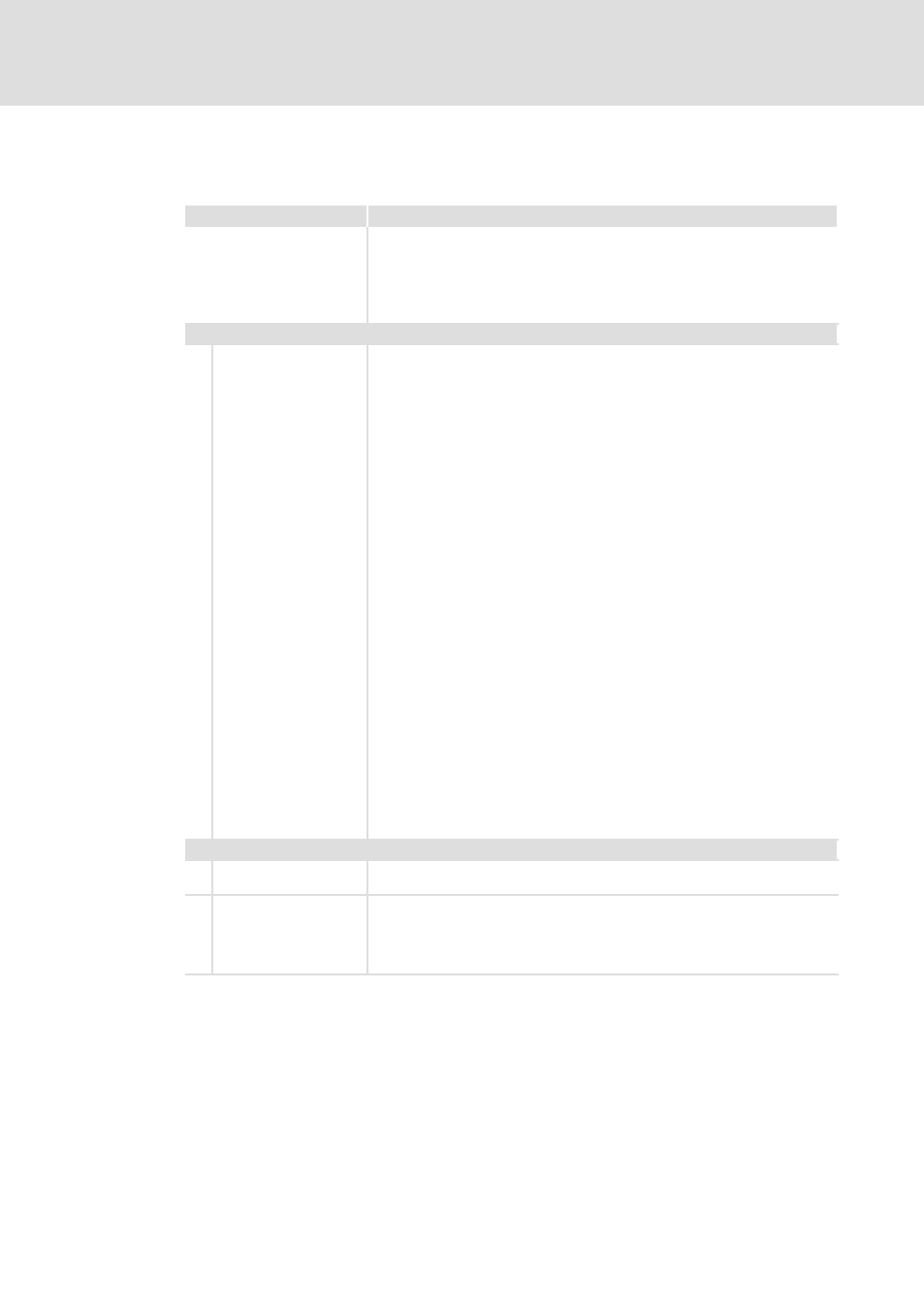

Commissioning steps for a mimimum configuration

The codes can be found in the GDC in the "Positioning/E−shaft" menu item.

Setting

Brief description

Preconditions

l

Wiring of the MotionBus (CAN) X4 with the master control (PLC) which acts as

electrical shaft master.

l

Connection of a PC via the "Global Drive Control" (GDC) operating program to

the system bus (CAN) X14 for parameterisation.

l

Information on selection and configuration of the control interface to control

the drive system can be found on

^ 226.

Settings for the master (PLC)

1.

Configure master control

as electrical shaft master.

l

Set CAN node address of the CAN node.

l

Set the same CAN baud rate for all nodes.

l

Tx−COB−IDs; identifiers of the process data telegrams to the slaves

– The master transmits the process data to the slave drives via the process

data channel 1 (PDO1).

– The identifiers to be set of the individual output telegrams to the slaves

result from the CANopen convention:

Identifier = basic value + node address of the slave

– The slaves therefore only require few settings differing from the standard

settings for process data communication.

l

Rx−COB IDs, identifiers of the process data telegrams from the slaves

– The telegrams sent back from the slaves via PDO1 are received by the

master.

– The identifiers of the individual telegrams in standard setting of the slaves

also correspond to the CANopen convention and are calculated as follows:

Identifier = basic value + node address of the slave

l

Cyclically send a CAN sync telegram (

^ 420) with the identifier = 0x80.

l

Master setpoint cycle; Interval in which the process data and the CAN sync

telegram are transmitted by the master

– The setpoint cycle is to amount to 2, 4 or 6 ms.

Note: The set interval time for the setpoint cycle must be complied exactly

with regard to a long−term medium.

A jitter of single CAN sync telegrams of up to one telegram runtime is

non−critical if the long−term medium is complied with. In case of CAN, delays

may occur due to telegrams being in transmission since running telegrams

cannot be interrupted.

l

If required, provide for monitoring of the response telegrams from the slaves.

l

Generation of the master value/master angle to be transmitted to the slaves

– Telegram structure see

– The master angle is transmitted in bytes 5 ... 8 (PosDirect).

– Information on selection and configuration of the control interface to

control the drive system can be found on

^ 226.

Settings for the slave drive

2.

Carry out CAN settings.

l

C0350 = x; set the CAN node address of the CAN node.

l

C0351 = 500 kbps; set the same CAN baud rate for all nodes.

3.

Configure process data

channel 1 (PDO1) as

input channel.

l

C4010 = 0; select control interface "CAN1 (PDO1, sync−controlled)".

l

C0353/1 = 0; set the ID creation mode for CAN1_IN/OUT to "Identifier = base

value + node address C0350".

– C0355/1: Display of the identifier CAN1_IN of the slave

– C0355/2: Display of the identifier CAN1_OUT of the slave