Commissioning – Lenze ECSCPxxx User Manual

Page 218

Commissioning

Configuring the electrical shaft ("E−Shaft")

Electrical shaft via MotionBus (CAN) with ECSxP as electrical shaft master

l

218

EDBCSXP064 EN 8.0

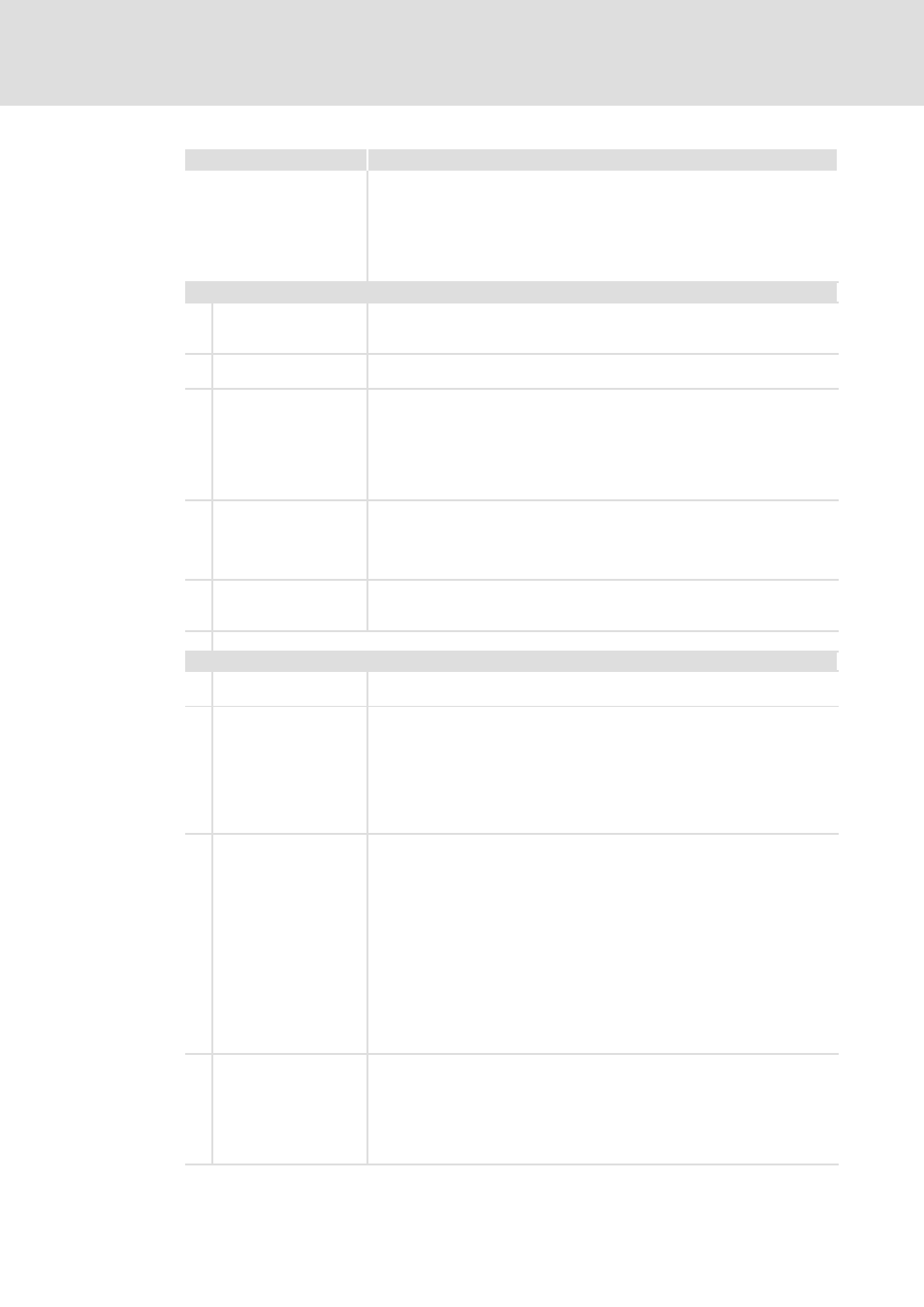

Setting

Brief description

Preconditions

l

Wiring of the MotionBus (CAN) X4 for the master value transmission

l

Wiring of the system bus (CAN) X14 for the control and coordination of the

drive system by the master control (PLC)

l

A PC with the "Global Drive Control" (GDC) operating program can be

connected to the system bus (CAN) X14 for parameterisation.

l

Information on selection and configuration of the control interface to control

the drive system can be found on

^ 226.

Settings for the master drive

1.

Carry out CAN settings.

l

C0350 = x; set the CAN node address of the CAN node.

l

C0351 = 500 kbps; set the same CAN baud rate for all nodes.

l

C0353/2 = 0; leave ID creation mode in default setting.

2.

Carry out boot−up

settings.

l

C0352 = 1; set master boot−up.

l

C0356/1 = 3000 ms; leave default setting.

3.

Set transmission cycle for

the setpoints.

l

C4062 = 2 ms; Electrical shaft − setpoint cycle of master (recommendation)

The cycle time setting under code C4062 is automatically accepted into the

codes C0369 (CAN−sync transmission cycle) and C0356/2 (CAN2−OUT

transmission cycle)

l

C0355/4; display: Identifier CAN2_Out.

Take a note of the displayed identifier for the CAN2−Out of the master to be

able to set the suitable identifiers in the slaves.

4.

Define positioning profile

for the operation.

l

Go to positioning profiles in the GDC parameter menu and create the

positioning profiles required for your application; e.g. with absolute

positioning or relative positioning in the continuous measuring system. (see

brief description

^ 123.)

l

Do not start the profiles yet!

5.

Save settings with mains

failure protection.

l

C0003 = 1; save parameter set 1.

The settings for the master drive are now completed.

6.

GDC: change to online connection to the slave drive.

Settings for the slave drive

7.

Carry out CAN settings.

l

C0350 = x; set the CAN node address of the CAN node.

l

C0351 = 500 kbps; set the same CAN baud rate for all nodes.

8.

Configure process data

channel 1 (PDO1) as

input channel.

l

C4010 = 0; select control interface "CAN1 (PDO1, sync−controlled)".

l

C0353/1 = 1; set ID creation mode for CAN1_IN/OUT to "Identifier = 384 +

ID−Offset C0354".

l

C0354/1 = xx ; set ID offset CAN1_IN as follows:

– ID offset = (value written down from C0355/4 − 384)

– Check: The identifier displayed in the slave under C0355/1 for CAN1_IN

must be equal to the identifier written down from CAN2_OUT of the

master.

9.

Set the synchronisation

of the program cycles by

means of a CAN sync

telegram.

l

C1120 = 1; set the source of the sync signal to "CAN Sync MotionBus X4" (the

synchronisation function will be activated).

l

C1121 = 2 ms; set the same time for the synchronisation cycle as for the

master under C4062.

l

C1122 = 0.800 ms; set the synchronisation phase.

– Recommendation: 0.8 ms for baud rate = 500 kbps and synchronisation

cycle = 2 ms

l

C1123 = 0.4 ms; synchronisation window, set time.

– Recommendation: 0.4 ms for baud rate = 500 kbps and synchronisation

cycle = 2 ms

l

C0363 = 1; set sync correction increment.

– Standard setting = 1 (0.2

ms/ms)

– Select the correction increment so that the synchronisation deviation in

code C4264 is about 0. (Recommendation: 0.2

ms/ms)

10. Set monitoring of the

CAN communication.

Settings in the GDC under "Monitoring − CAN MotionBus" menu

l

C0357/1 = 3000 ms; set CAN1_IN monitoring time (CE1).

– Standard setting = 3000 ms

– If the reception at CAN1_IN of the slave is disturbed longer than the

monitoring time, the fault response set under code C0591 will be carried

out.

l

C0591 = 0; set CE1 fault response to TRIP or warning.