Commissioning – Lenze ECSCPxxx User Manual

Page 217

Commissioning

Configuring the electrical shaft ("E−Shaft")

Electrical shaft via MotionBus (CAN) with ECSxP as electrical shaft master

l

217

EDBCSXP064 EN 8.0

6.18.3

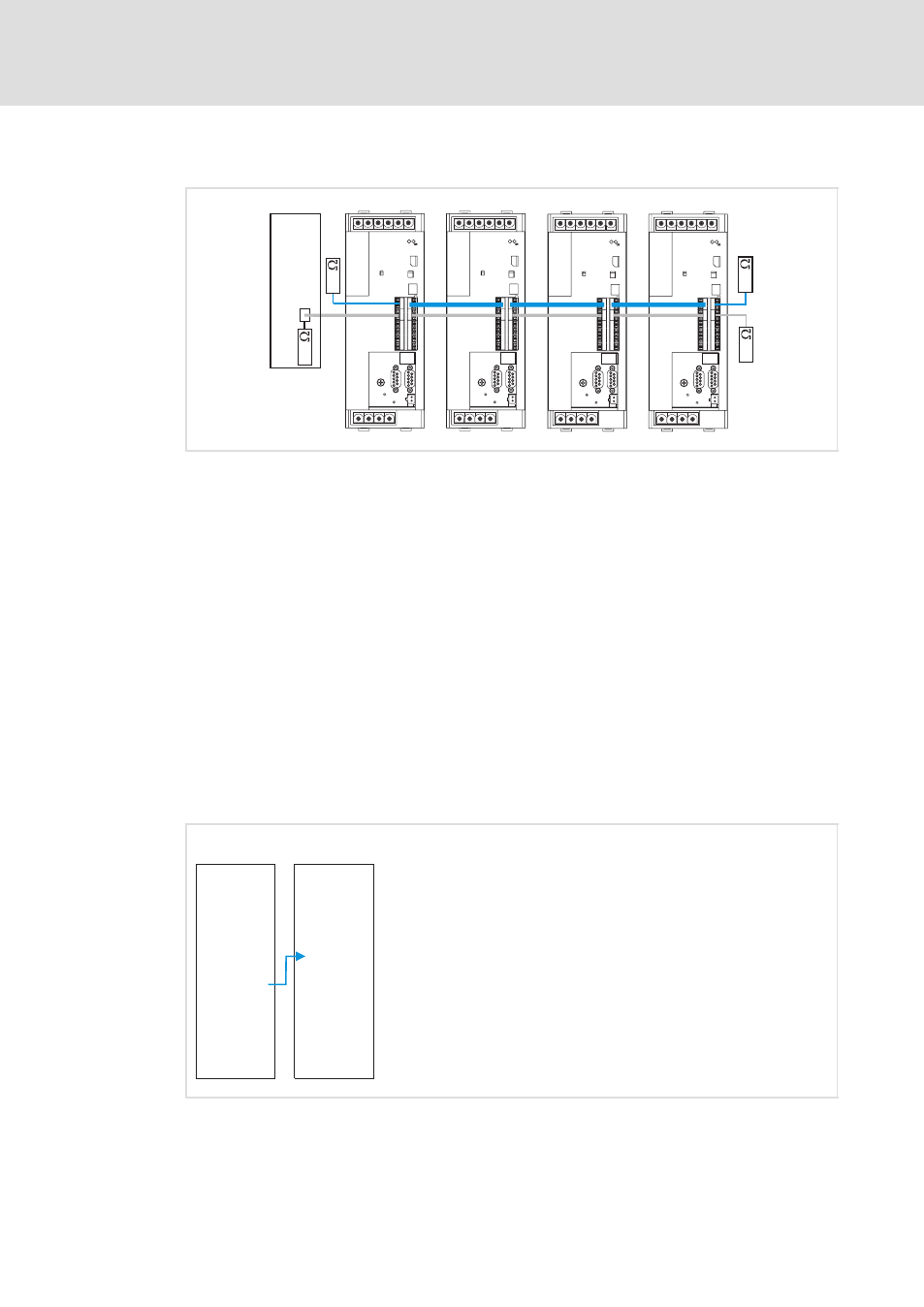

Electrical shaft via MotionBus (CAN) with ECSxP as electrical shaft master

X

S

X4

X14

X4

X14

X4

X14

X4

X14

120

120

120120

120120

E-Shaft Master

Slave 3

Slave 2

Slave 1

PLC

ECS

ECS

ECS

ECS

ECSXP002

Fig. 6−52

Electrical shaft via MotionBus (CAN), control via system bus (CAN)

PLC

Master control (PLC) or a PLC device to control the drive system

E−shaft master Master value master (axis module ECSxP)

Slave 1 ... 3

Slave drives (ECSxP axis modules )

The following special features apply to the master value transmission per MotionBus

(CAN) X4 between master and slave/slaves:

ƒ

The master transmits the master values per process data channel 2 (PDO2−OUT) and

the slaves receive these via the process data channel 1 (PDO1−IN).

ƒ

For acceptance of the data of PDO1 in the slaves, the reception of a CAN sync

telegram is required. The CAN sync telegram is transmitted by the master.

ƒ

In this configuration with an ECSxP axis module as frequency master, the slave

drives do not return any status telegrams back to the master via the MotionBus

(CAN) at (X4).

ƒ

The control and coordination of the master control (PLC) is executed via the system

bus (CAN) at X14. Here, the control and status information are exchanged

accordingly.

E-Shaft

Master

E-Shaft

Slave 1 ... n

ECS

ECS

CAN1-Out

CAN2-Out

CAN3-Out

CAN1-In

CAN2-In

CAN3-In

ECSXP006

Fig. 6−53

MotionBus (CAN) telegram structure

Commissioning steps for a mimimum configuration

The codes can be found in the GDC in the "Positioning/E−shaft" menu item.