10 machine parameters, Machine parameters, Commissioning – Lenze ECSCPxxx User Manual

Page 103

Commissioning

Basic terms of positioning

Machine parameters

l

103

EDBCSXP064 EN 8.0

6.1.10

Machine parameters

A positioning process requires the machine parameters to convert the entries in the

application units into a device−internal incremental representation (inc). The GDC contains

the codes for setting the machine parameters in the parameter menu under Positioning

W

Machine parameters. (

¶ 165)

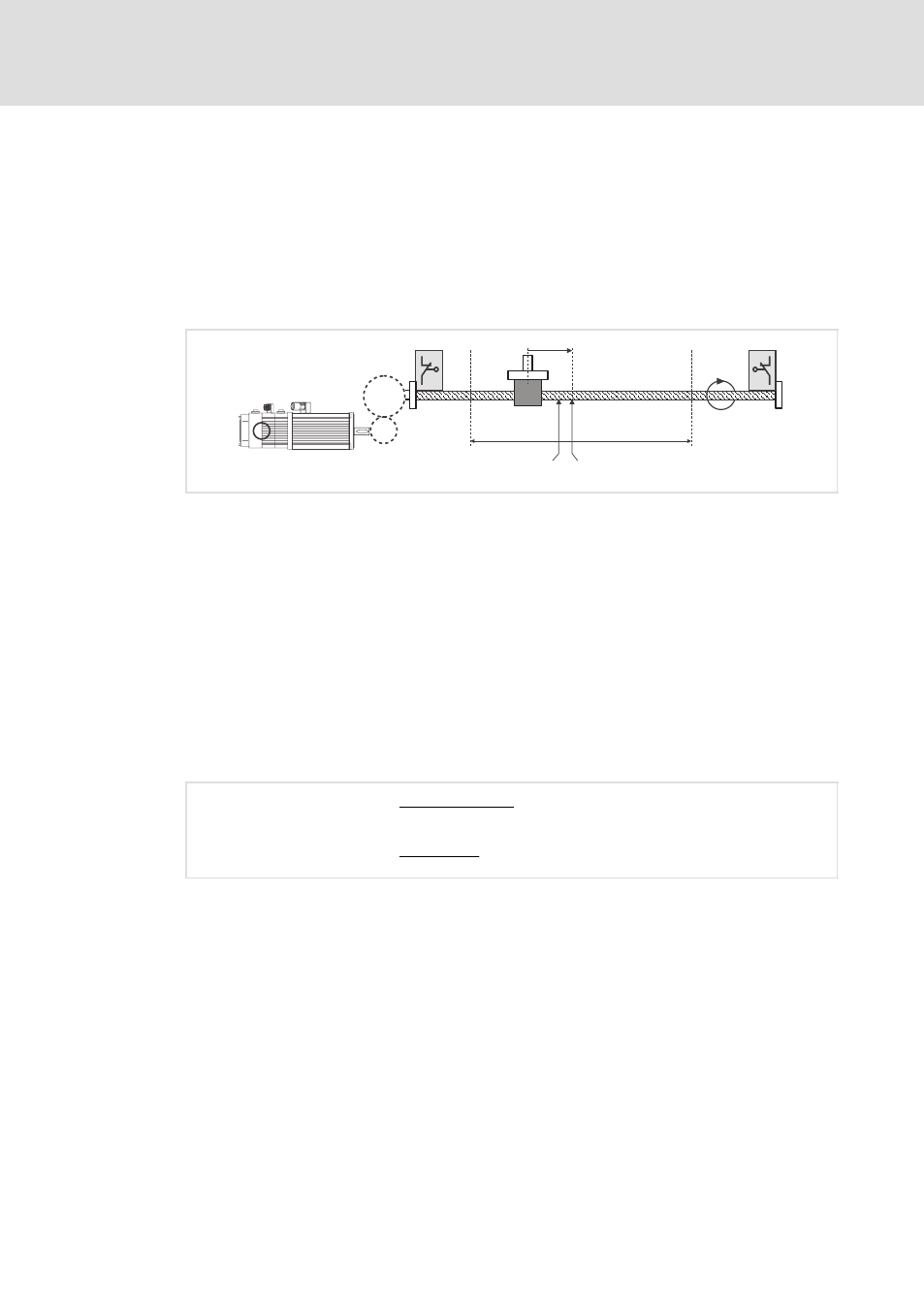

The machine parameters are explained in detail considering as example the operation of

a linear positioning axis with spindle which is provided with a movable slide:

Zero position

3000 mm

-2000 mm

i = 12.39

h = 20

s = 1000 mm

Target position

Z2

Z1

R

ECSXA417

Fig. 6−12

Example: Linear positioning axis with spindle

Motor/encoder

Gearbox with transmission ratio i = Z2 / Z1 (ratio of the tooth numbers or circumferences) or

i = n1/n2 (ratio of the speeds)

Negative software limit position

Positive software limit position

Feed constant (in mm/revolution), h = leadscrew pitch

The parameters for the positioning profile (target position, traversing speed, acceleration

and deceleration) are specified in real units with regard to the slide (e. g. 1000 mm as

relative target position or distance).

Target position in number of motor revolutions or converted into increments

In order to move the slide exactly 1000 mm to the right, the motor must rotate a certain

number of times which results from the gearbox ratio (i) and the feed constant (h).

Motor revolutions

+ 1000 mm

20 mm

ńrev.

@ 12.39 + 619.5 revolutions

Motor revolutions

+

Path (s)

Feed constant (h)

@ Gearbox ratio (i)

When multiplying the number of revolutions by the fixed position resolution of

65536 incr/rev. you obtain the distance to be traversed with internal incremental

representation.