Commissioning – Lenze ECSCPxxx User Manual

Page 215

Commissioning

Configuring the electrical shaft ("E−Shaft")

Electrical shaft via classical digital frequency coupling (digital frequency input X8)

l

215

EDBCSXP064 EN 8.0

6.18.2

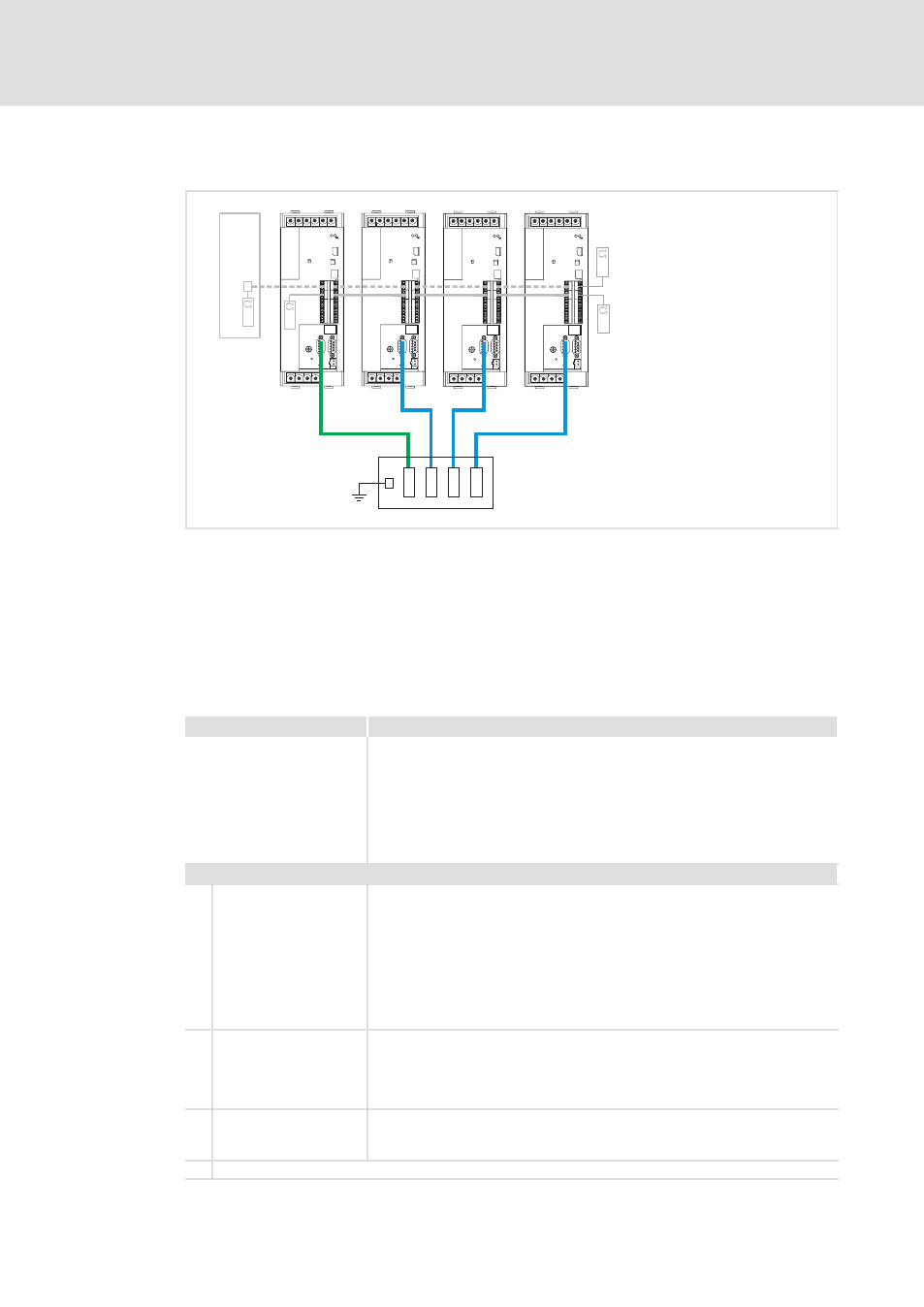

Electrical shaft via classical digital frequency coupling (digital frequency input X8)

X8

X8

X8

X8

0

1

1

1

E-Shaft Master

Slave 3

Slave 2

Slave 1

X

S

PLC

X4

X4

X4

X4

120

ECS

ECS

ECS

ECS

X1

X5

X2

X3

X4

EMF2132IB

120

120

X14

X14

X14

X14

120

120

120

ECSXP001

Fig. 6−51

ECS axis modules in the digital frequency network with digital frequency distributor EMF2132IB

PLC

Master control (PLC) or a PLC device to control the drive system

E−Shaft master Master value master (axis module ECSxP)

Slave 1...3

Slave drives (ECSxPaxis modules )

0

Master digital frequency cable EYD0017AxxxxW01W01 (socket/socket)

1

Slave digital frequency cable EYD0017AxxxxW01S01 (plug/socket)

Commissioning steps for a mimimum configuration

The codes can be found in the GDC in the "Positioning/E−shaft" menu item.

Setting

Brief description

Preconditions

l

Wiring of the digital frequency connection between interface X8 of the drive

controllers and the digital frequency distributor EMF2132IB

l

Wiring of the MotionBus (CAN) X4 for the control and coordination of the

drive system by the master control (PLC)

l

Connection of a PC via the "Global Drive Control" (GDC) operating program to

the system bus (CAN) X14 for parameterisation

l

Information on selection and configuration of the control interface to control

the drive system can be found on

^ 226.

Settings for the master drive

1.

Configure digital

frequency output.

l

C0491 = 1; configuration of signal direction at X8 = digital frequency output

l

C0540 = 1 or 2; set output function of X8

– 1: Digital frequency derived from setpoint (profile generator output)

– 2: Digital frequency derived from actual value (encoder simulation + zero

pulse)

l

C0030 = 2048; set DFOUT constant for the digital frequency output X8

– Standard setting: 2048 inc/rev

l

C0545 = 0 inc; set DFOUT angular offset

– Recommendation: 0 Inc

2.

Define positioning profile

for the operation.

l

Go to positioning profiles in the GDC parameter menu and create the

positioning profiles required for your application; e.g. with absolute

positioning or relative positioning in the continuous measuring system. (see

brief description

^ 123.)

l

Do not start the profiles yet!

3.

Save settings with mains

failure protection.

l

C0003 = 1; save parameter set 1 safe against mains failure.

The settings for the master drive are now completed.

4.

GDC: change to online connection to the slave drive.