3 communications with plcs, Command construction – Yokogawa Data Acquisition with PID Control CX2000 User Manual

Page 115

5-5

IM 04L31A01-17E

5

Ladder Communication Protocol

5.3

Communications with PLCs

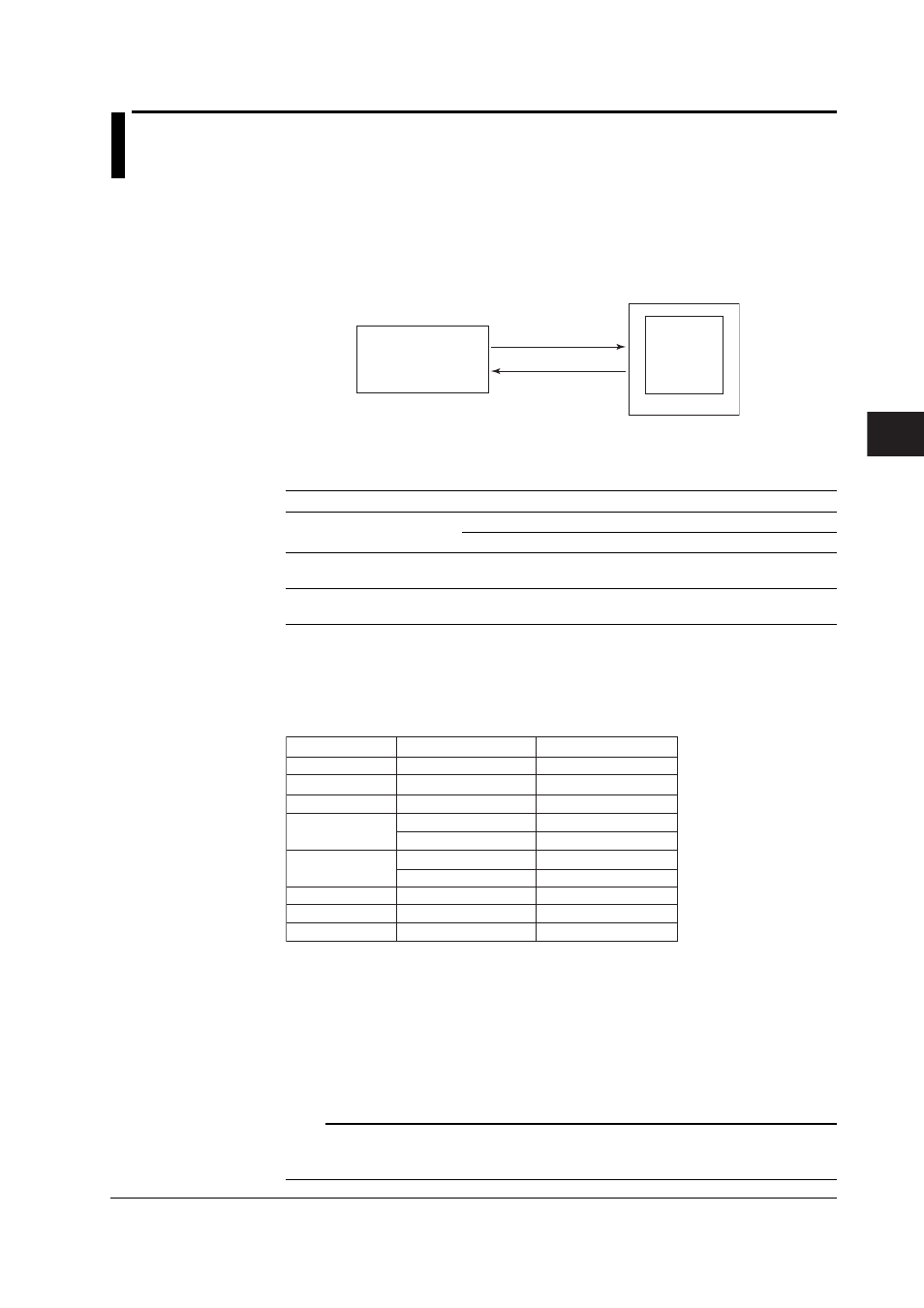

When performing ladder communications, make sure the PLC (host) first sends a

command to the CX. When the CX receives a command from a PLC, the CX executes

the specified operation, provided that no errors are present in the received command,

and returns a response to the PLC. If an error is present in the command, the CX

returns an error code corresponding to the error type to the PLC.

Command

Response

CX

PLC

The PLCs that the CX can communicate with are those that support the ladder

communication protocol.

Connectable PLCs are indicated below.

Distributor

Product Name

Requirements

YOKOGAWA

FA500

With communication module (RZ91-0N)

FA-M3

With communication module (F3RZ91-0N)

Mitsubishi Electric Corporation MELSEC-A Series

With computer link module

and others

Others

PLCs that can use the With module for RS-232 or RS-422/485

non-procedural mode

For information on the PLCs, contact the respective distributor. For details, refer to the instruction

manual for the PLC to be connected.

Command Construction

The figure below illustrates the construction of the commands that PLCs transmit.

Number of Bytes Number of BCD Digits

Command Element

1

1

2

1

1

2

1

1

2

2

4

1

1

1

1

4

2

2

Station number

CPU number (01)

D register number

0

5th digit

R/W

+/–

Read and write data

CR

LF

• Station number (1-32)

The number used by the PLC to identify the communication destination. The serial

interface address of the CX to which commands are sent is specified here.

• CPU number

Fixed to “01”.

• D register number

The D register number is specified using a 4-digit BCD value excluding the “D”.

Note

In ladder communications, the D register number is specified using BCD codes. BCD is a

method of using 4 bits to represent the decimal digits 0 through 9. For example, the value 99

expressed using 1-byte BCD code is “10011001” (not “01100011”).