Heat and cool outputs, Heat and cool outputs 114 – Watlow Series D8 User Manual

Page 132

Chapter 5: Tuning and Control

Series D8 User’s Guide

114

Watlow Anafaze

Doc. 0600-3120-2000

Proportional, Integral and Derivative Control (PID)

Derivative control corrects for overshoot by anticipating the

behavior of the process variable and adjusting the output ap-

propriately. For example, if the process variable is rapidly ap-

proaching the set point from below, derivative control reduces

the output, anticipating that the process variable will reach set

point. Use derivative control to reduce the overshoot and os-

cillation of the process variable that is common to PI control.

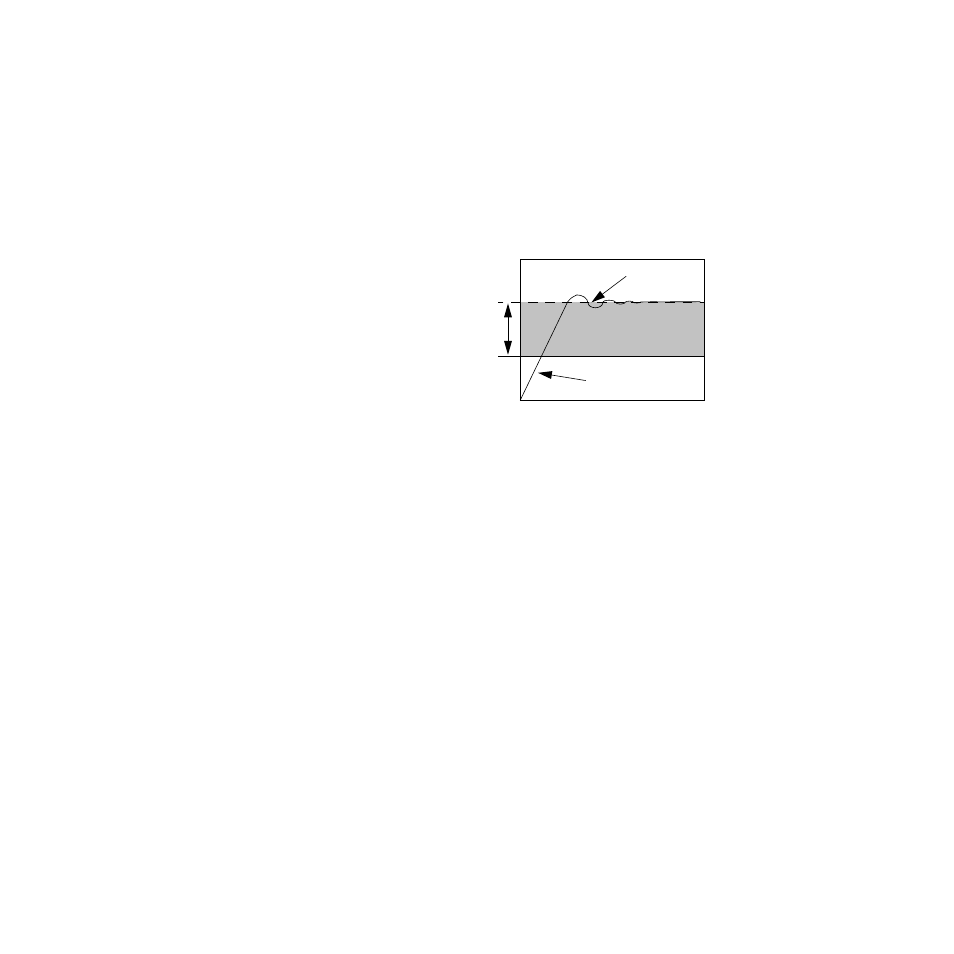

Figure 5.4 shows a process under full PID control.

Figure 5.4

Proportional, Integral and Deriva-

tive Control

Heat and Cool Outputs

Each loop may have one or two outputs. Often a heater is con-

trolled according to the feedback from a thermocouple, in

which case only one output is needed.

In other applications, two outputs may be used for control ac-

cording to one input. For example, a system with a heater and

a proportional valve that controls cooling water flow can be

controlled according to feedback from one thermocouple.

In such systems, the control algorithm avoids switching too

frequently between heat and cool outputs. The on/off algo-

rithm uses the control hysteresis parameter to prevent such os-

cillations (see Hysteresis on page 138). When PID control is

used for one or both loop outputs, both the hysteresis param-

eter and PID parameters determine when control switches be-

tween heating and cooling.

Proportional

Set Point

Process Variable

Band