Setting up ratio control, Setting up ratio control 104, Variable in cascade example 104 – Watlow Series D8 User Manual

Page 122

Chapter 4: Operation and Setup

Series D8 User’s Guide

104

Watlow Anafaze

Doc. 0600-3120-2000

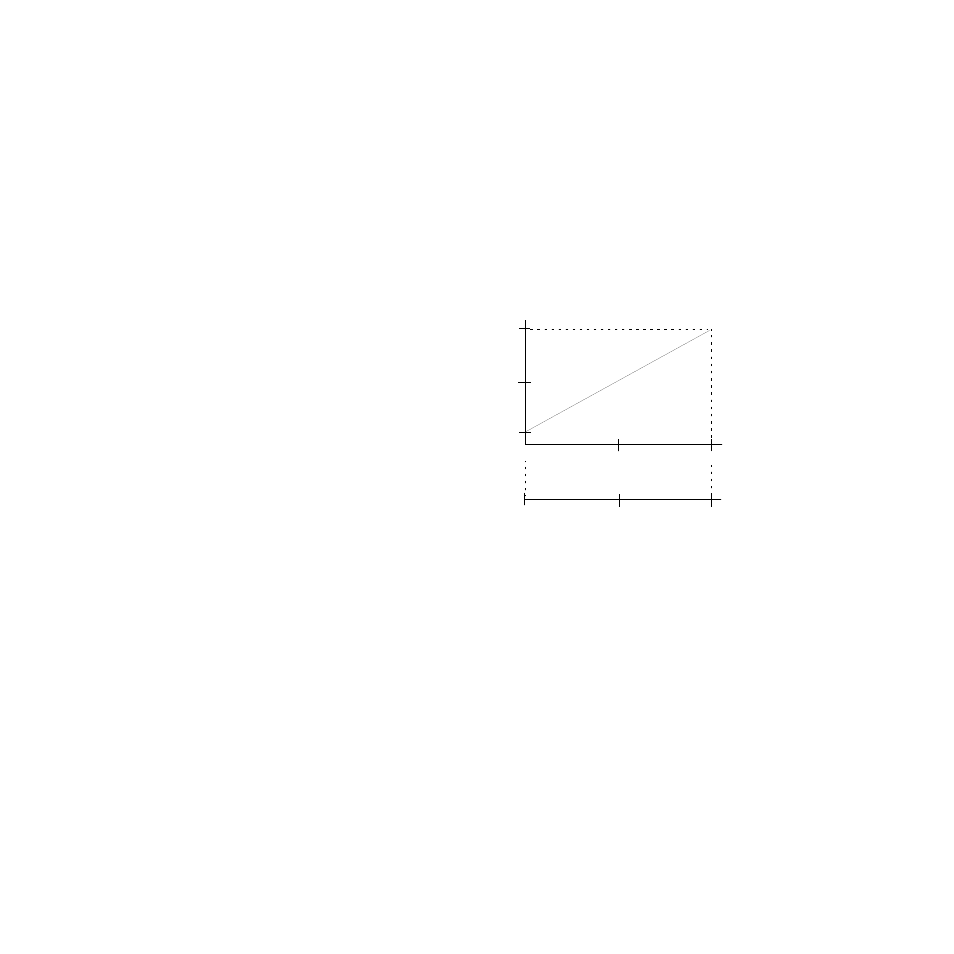

With proportional control, when loop 1 is at set point, its out-

put is 0 percent, and the set point of loop 2 is equal to the de-

sired temperature 150º F. If the temperature of the loop 1

drops below 149º F, the deviation results in a proportional out-

put of 10 percent. This results in an increase to the set point

for loop 2 equal to 10 percent of the set point range. In this

case the range is 40º F (190º F - 150º F = 40º F), and 10 percent

of 40º F is 4º F.

So when the temperature at loop 1 drops 1º F, the set point of

loop 2 increases by 4º F until the output of loop 1 is 100 per-

cent and the set point of loop 2 is 190º F. At this point, further

decreases of the loop 1 process variable have no additional af-

fect on loop 2. Figure 4.12 illustrates this relationship.

Figure 4.12 Relationship of Secondary Loop

Set Point to Primary Loop Process

Variable in Cascade Example

Setting Up Ratio Control

Ratio control allows the process variable of one loop (master

loop), multiplied by a ratio, to be the set point of another loop

(ratio loop). You can assign any process variable to determine

the set point of a ratio loop.

By adjusting the ratio control parameters, you can adjust the

influence that the master loop process variable has on the set

point of the ratio loop.

Set Point of the Secondary Loop

(Engineering Units)

Process Variable of Primary Loop (ºF)

Heat Output of Primary Loop

(Percent of Full Scale)

0%

50%

100%

150º F

145º F

140º F

190º F

170º F

150º F