On/off control, Proportional control (p), On/off control 112 – Watlow Series D8 User Manual

Page 130: Proportional control (p) 112, Figure 5.1—on/off control 112

Chapter 5: Tuning and Control

Series D8 User’s Guide

112

Watlow Anafaze

Doc. 0600-3120-2000

On/Off Control

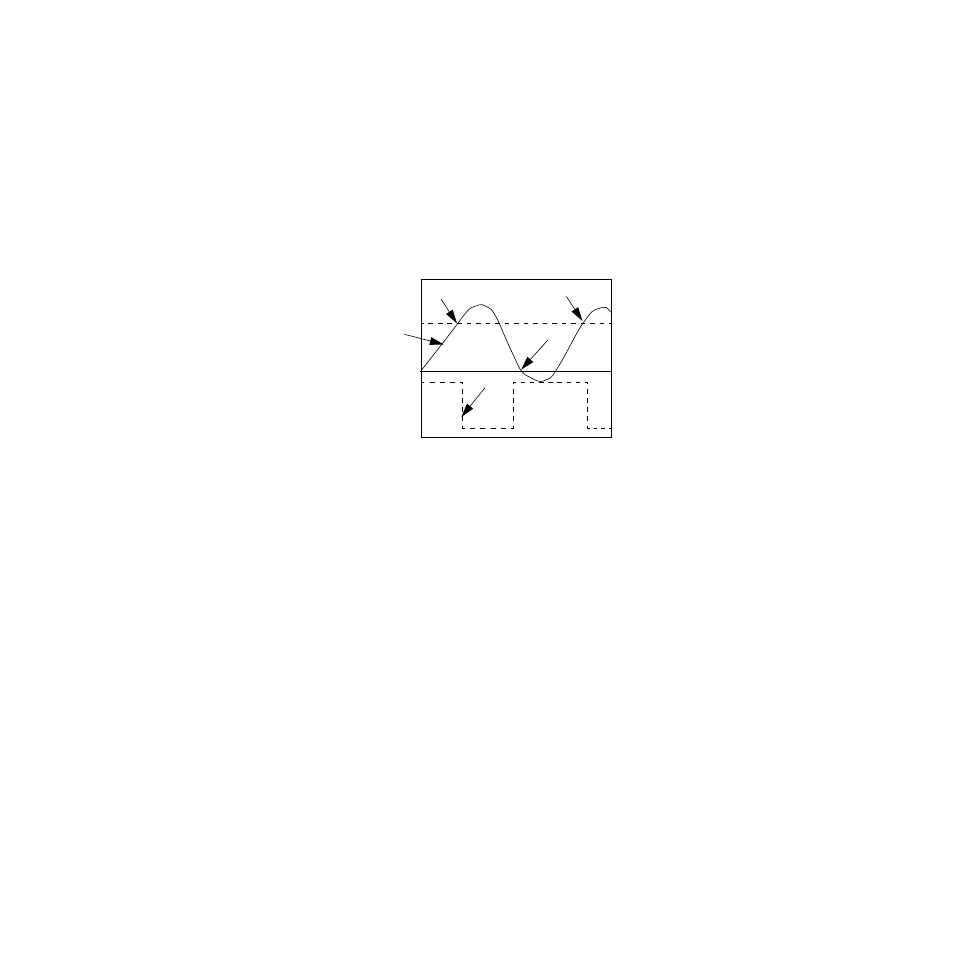

On/off control is the simplest way to control a process. The

controller turns an output on or off when the process variable

reaches limits around the desired set point. This limit is adjust-

able.

For example, if the set point is 1000° F and the control hyster-

esis is 20° F, the heat output switches on when the process

variable drops below 980° F and off when the process rises

above 1000° F. A process using on/off control cycles around

the set point. Figure 5.1 illustrates this example.

Figure 5.1

On/Off Control

Proportional Control (P)

Proportional control eliminates cycling by increasing or de-

creasing the output proportionally with the process variable’s

deviation from the set point.

The magnitude of proportional response is defined by the pro-

portional band. Outside this band, the output is either 100 per-

cent or 0 percent. Within the proportional band the output

power is proportional to the process variable’s deviation from

the set point.

For example, if the set point is 1000° F and the proportional

band is 20° F, the output power is as follows:

•

0 percent when the process variable is 1000° F or above

•

50 percent when the process variable is 990° F

•

75 percent when the process variable is 985° F

•

100 percent when the process variable is 980° F or below

However, a process that uses only proportional control settles

at a point above or below the set point; it never reaches the set

point. This behavior is known as offset or droop. When using

proportional control, configure the manual reset parameter for

the power level required to maintain set point.

Heat Off

Heat On

Set Point

Set Point - Hysteresis

Process

On

Heat Off

Output

Off

Variable

980

°

F

1000

°

F