Rockwell Automation 2711 PANELBUILDER SOFTWARE USER MANUAL User Manual

Page 83

Planning Your Application

Chapter 4

4-8

3.

With the Object Address List, define the discrete or block transfer

PLC addresses for each object on your screen.

4.

Enter the object reference number and screen number on the I/O

Usage Worksheets to map your PLC memory usage. Use the Discrete

I/O Usage Worksheet for discrete addresses. Use both the Discrete

I/O Usage Worksheet and the Block Transfer I/O Usage Worksheet

for Block Transfer Files. Use the Discrete worksheet to record any

block transfer control bytes in both the Input and Output sections of

the image table.

5.

Use a new Screen Worksheet and Object Address List for each

screen. Use one Discrete I/O Usage Worksheet for each full or partial

rack assignment, and two Block Transfer I/O Usage Worksheets for

each block transfer file.

6.

Use a separate Object Address List to record the addresses for your

windows and PLC controlled options, and map these addresses onto

the I/O Usage Worksheets. You may also wish to record all the

messages associated with the Alarm and Information windows, and

the Local Message Display object.

7.

Only after you’ve finished assigning addresses to your objects,

windows and PLC controlled options will you know exactly how

many racks to assign to your PanelView terminal. Enter this

information on the PLC Communications Worksheet.

8.

Calculate the size of the application file: your PanelView memory

requirements can’t exceed the terminal’s capabilities. Refer to

Table 4.E and

Table 4.J

.

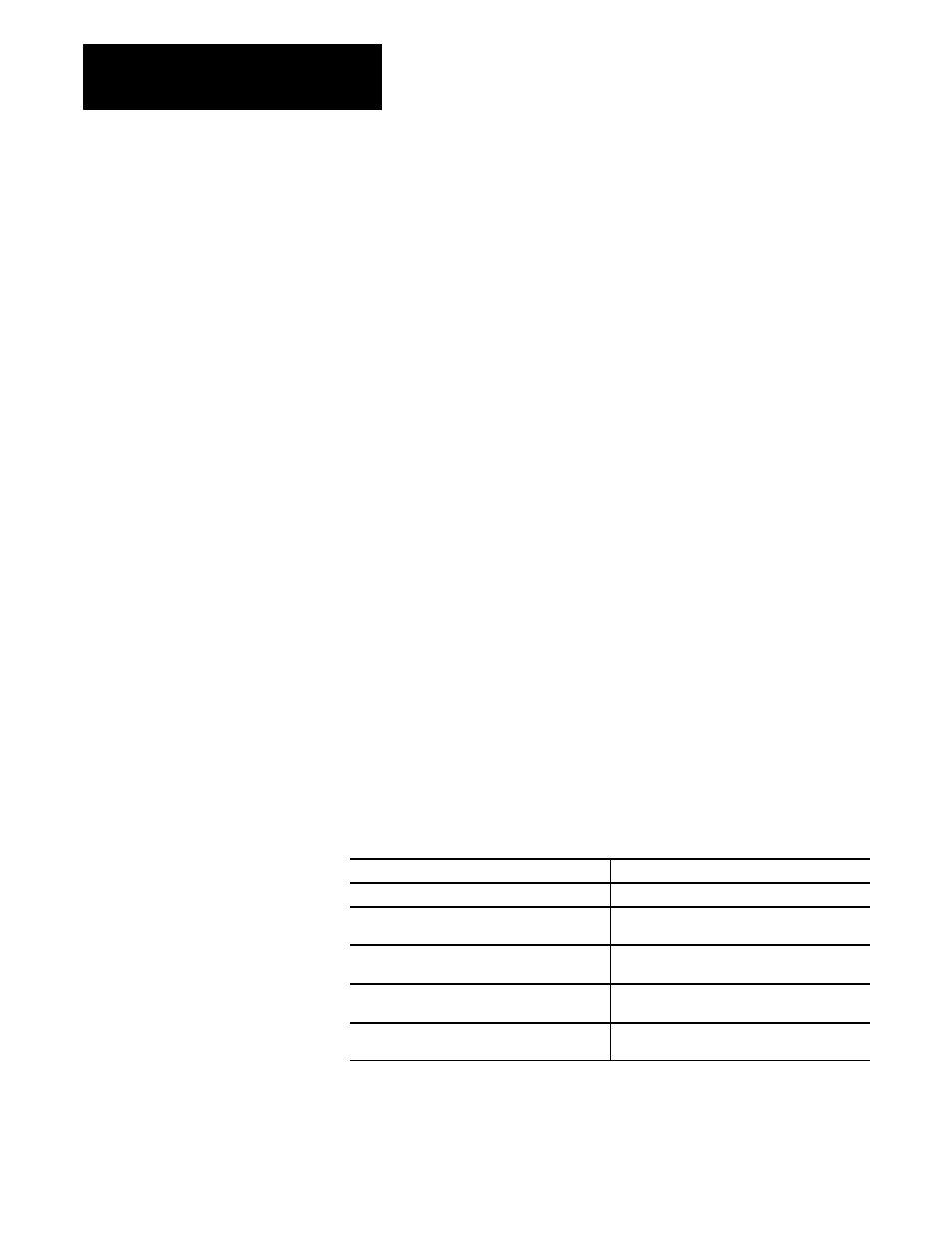

Table 4.E

Terminal Memory Limits (in bytes):

Firmware

Bytes of Memory

V1 and V2 firmware

62,976

V3, V4 and V5 firmware without retained alarm

data

62,976

V3, V4 and V5 firmware with retained alarm

data

59,904

V3, V4 and V5 firmware with 64k extra

EEPROM memory without retained alarm data

128,000

V3, V4 and V5 firmware with 64k extra

EEPROM memory with retained alarm data

124,928