Planning your application chapter 4 – Rockwell Automation 2711 PANELBUILDER SOFTWARE USER MANUAL User Manual

Page 105

Planning Your Application

Chapter 4

4-30

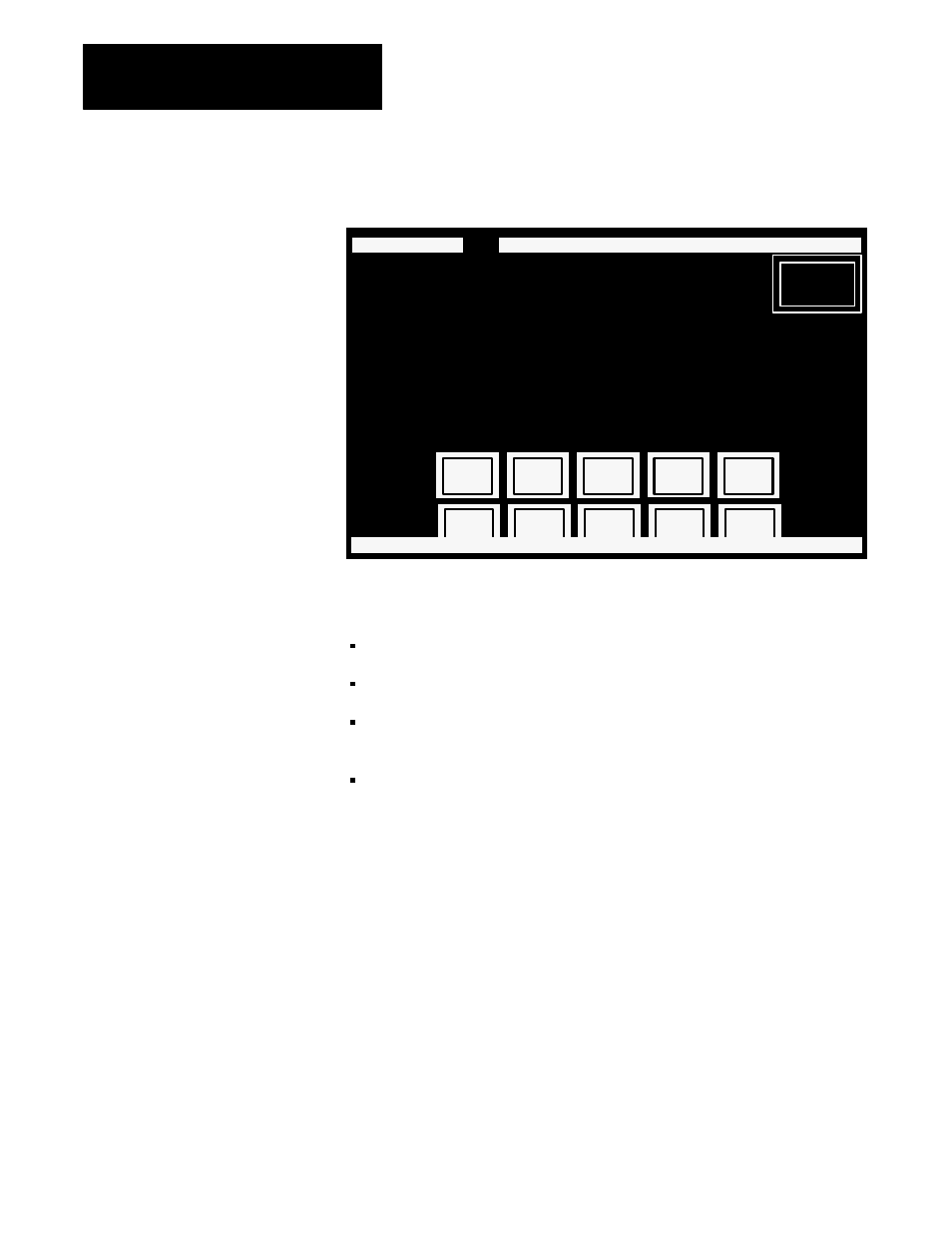

Figure 4.11

Screen 2 The Conveyor Controls Screen

22089

SCREEN MENU:

Add

Edit Move Delete Memorize Recall Options Exit

FRONT

FRONT

CENTER

CENTER

BACK

CENTER

BACK

MAIN

SCREEN

C

.

O

.

N

.

V

.

E

.

Y

.

O

.

R

.

G

.

C

.

O

.

N

.

T

.

R

.

O

.

L

.

S

.

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

V1 Size: 2,243 Screen: 2 CONVEYOR Oct 15 1992 12:31

O

.

N

.

O

.

N

.

O

.

N

.

O

.

N

.

O

.

N

.

O

.

F

.

F

.

O

.

F

.

F

.

O

.

F

.

F

.

O

.

F

.

F

.

O

.

F

.

F

.

Screen 2 consists of:

one Text object with the screen title CONVEYOR CONTROLS

.

one “Return To Previous Screen” Button labeled MAIN SCREEN

.

five Momentary Push Buttons—Normally Open with indicator state text

inside the buttons and “outer text” above the buttons

five Momentary Push Buttons—Normally Closed with indicator state

text inside the buttons

Each push button has two possible states to which different text and

attributes will be assigned.

Each of the ten push buttons on this screen has a unique PLC input bit

address. You will program your PLC controller to turn on a conveyor when

its respective Momentary Push Button (Normally Open) is pressed, and to

turn it off again when its respective Momentary Push Button (Normally

Closed) is pressed.

Each of the ten buttons also has a unique PLC output bit address. These are

referred to as the “Indicator Control Bits”. Your PLC program should

include the logic to set the appropriate Indicator Control Bits to show that

the conveyor is on or off.