Ać13, Plc programming considerations appendix a, Input data (block transfer read) – Rockwell Automation 2711 PANELBUILDER SOFTWARE USER MANUAL User Manual

Page 377

PLC Programming Considerations

Appendix A

A-13

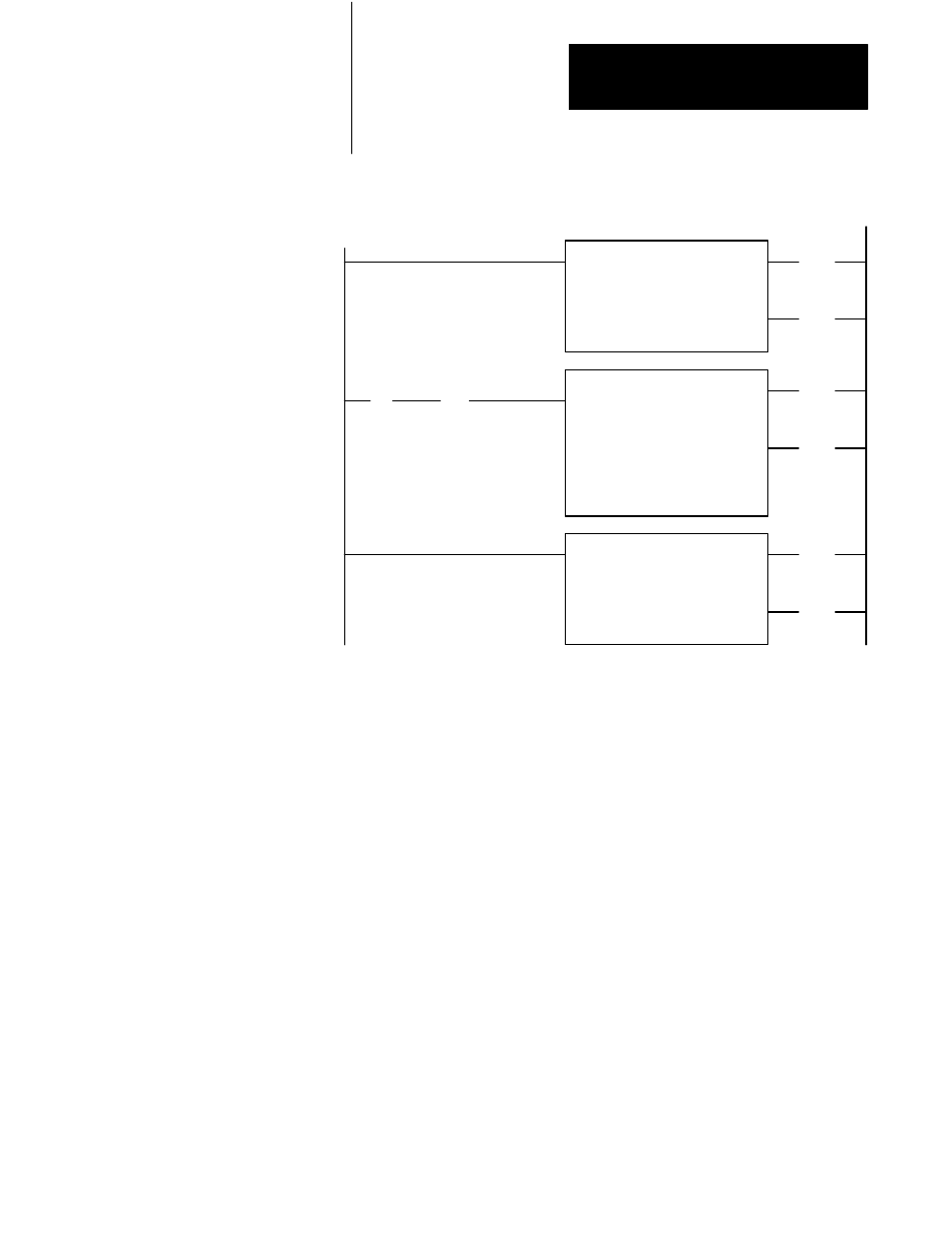

Figure A.8

Block Transfer Programming Example for Local PLCĆ2 Family Processor

DATA ADDR:

0030

MODULE ADDR:

131

BLOCK LENGTH:

24

FILE:

300- 327

BLOCK XFER READ

Local Processor

013

(EN)

17

Fault Bit

305

] / [

BTR

Done Bit

113

] [

17

00

20218

113

(DN)

17

COUNTER ADDR: 0040

POSITION:

001

FILE LENGTH:

19

FILE A: 0305- 0327

FILE R: 0405- 0427

RATE PER SCAN: 0

FILE TO FILE MOVE

0040

(EN)

17

0040

(DN)

15

DATA ADDR:

0031

MODULE ADDR:

131

BLOCK LENGTH:

24

FILE:

200- 227

BLOCK XFER WRITE

Buffer File

CNTL

(EN)

16

113

(DN)

16

Input Data (Block Transfer Read)

The 1771-SN formats input data received from the PanelView terminals

and block transfers this data to the PLC processor when enabled by your

ladder diagram program. Eight words are reserved for I/O data from each

full remote I/O chassis (Figure A.9). Do not use the first eight words (0

through 7 octal) for data from input modules. The remaining words (10–

77 octal) correspond to Remote I/O rack numbers 1–7. For example, word

10 (octal) corresponds to module group 0 of rack number 1. The most

significant byte is slot 1, the least significant byte is slot 0.

The reason for the additional length of BTR and BTW files is addressing

convenience. Word addresses for assigned rack 1 are 10–17, assigned rack

2 are 20–27, assigned rack 3 are 30–37, etc., in both files.