Plc-2/30 block transfer programming example, Ać10 – Rockwell Automation 2711 PANELBUILDER SOFTWARE USER MANUAL User Manual

Page 374

PLC Programming Considerations

Appendix A

A-10

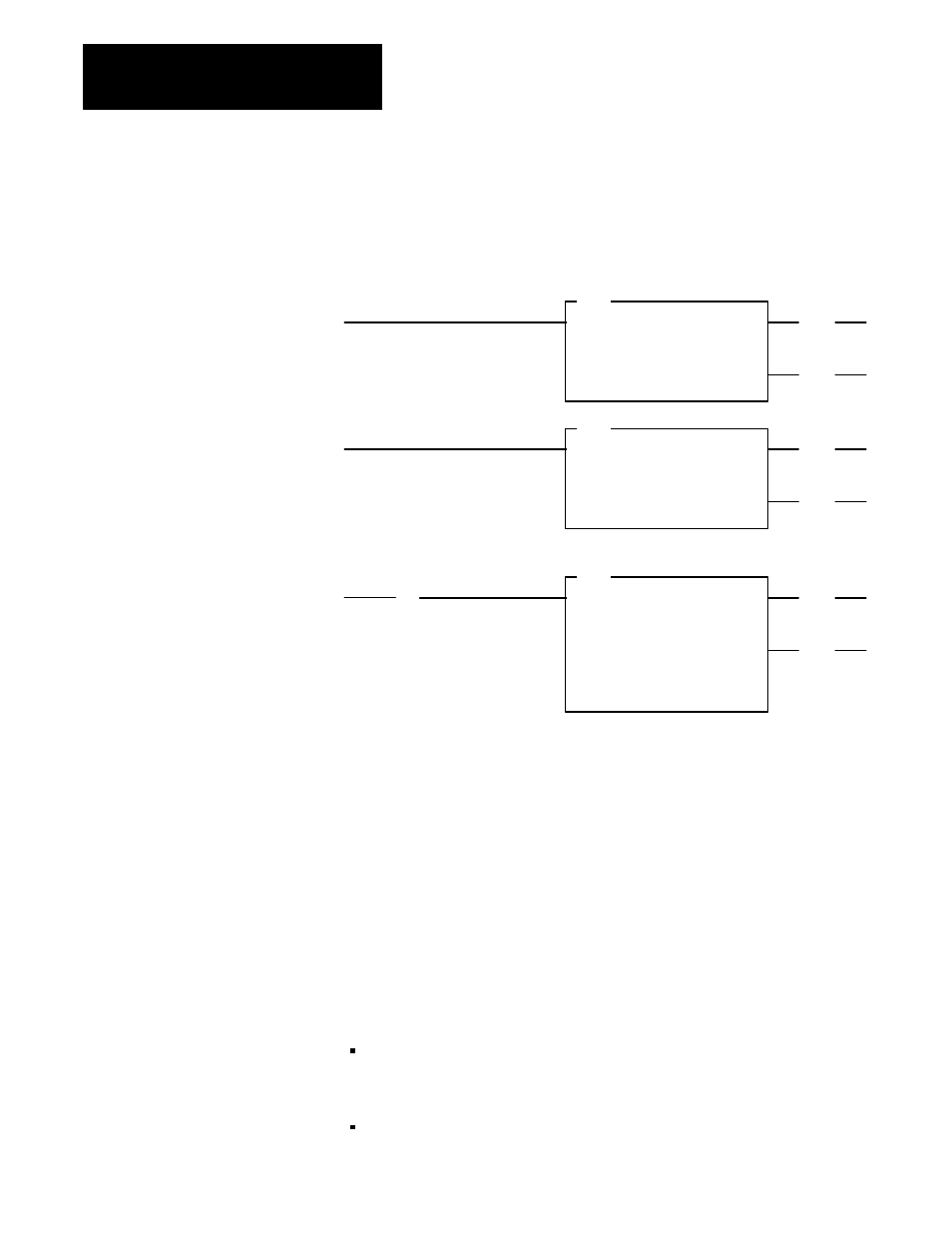

The following rung moves the block transfer read data into a “verified”

block transfer read file. The PLC program should only use data from the

“verified” read file.

Figure A.7

BiĆdirectional Block Transfer Example (PLCĆ2/30)

033

(EN)

17

20243

FFM

FILE TO FILE MOVE

Counter Addr:

033

Position: 001

File Length:

20

File A:

300 - 323

File R:

400 - 423

Rate Per Scan:

20

BTR

Done

110

] [

07

033

(DN)

15

010

(EN)

07

BTR

BLOCK TRANSFER READ

Data Addr:

030

Module Addr:

100

Block Length:

20

File:

300 - 323

110

(DN)

07

010

(EN)

06

BTW

BLOCK TRANSFER WRITE

Data Addr:

031

Module Addr:

100

Block Length:

20

File:

200 - 223

110

(DN)

06

To block transfer in a single direction, program a rung similar to the

corresponding block transfer rung shown above. Each block transfer read

instructions data should always be “verified” with a “file to file move” as

shown above.

IMPORTANT: If using a 1772-SD2 Remote I/O Scanner with a

PLC-2/30, you must use 1772-SD2 rev. 3 or later.

Use PLC-5 6200 software to configure a PLC-5/15 or 5/25 for

communication with remote I/O devices such as a PanelView terminal.

To use the following procedure your system must have this software:

PLC-5 6200 software release 2.2 or later

As well, you must have one of these PLC controllers:

PLC-5/15 Series B, rev. H or later

PLCĆ2/30 Block Transfer

Programming Example

Configuring a PLCĆ5 for

MultiĆChassis I/O Rack

Addressing