Overview of the engineering terminal, 1 engineering terminal, Overview of the engineering terminal -1 – Yokogawa GC8000 Process Gas Chromatograph User Manual

Page 17: Engineering terminal -1, Nengineering terminal, Nengineering terminal features

<1. Overvies of the Engineering Terminal>

1-1

IM 11B06C01-01E

1.

Overview of the Engineering Terminal

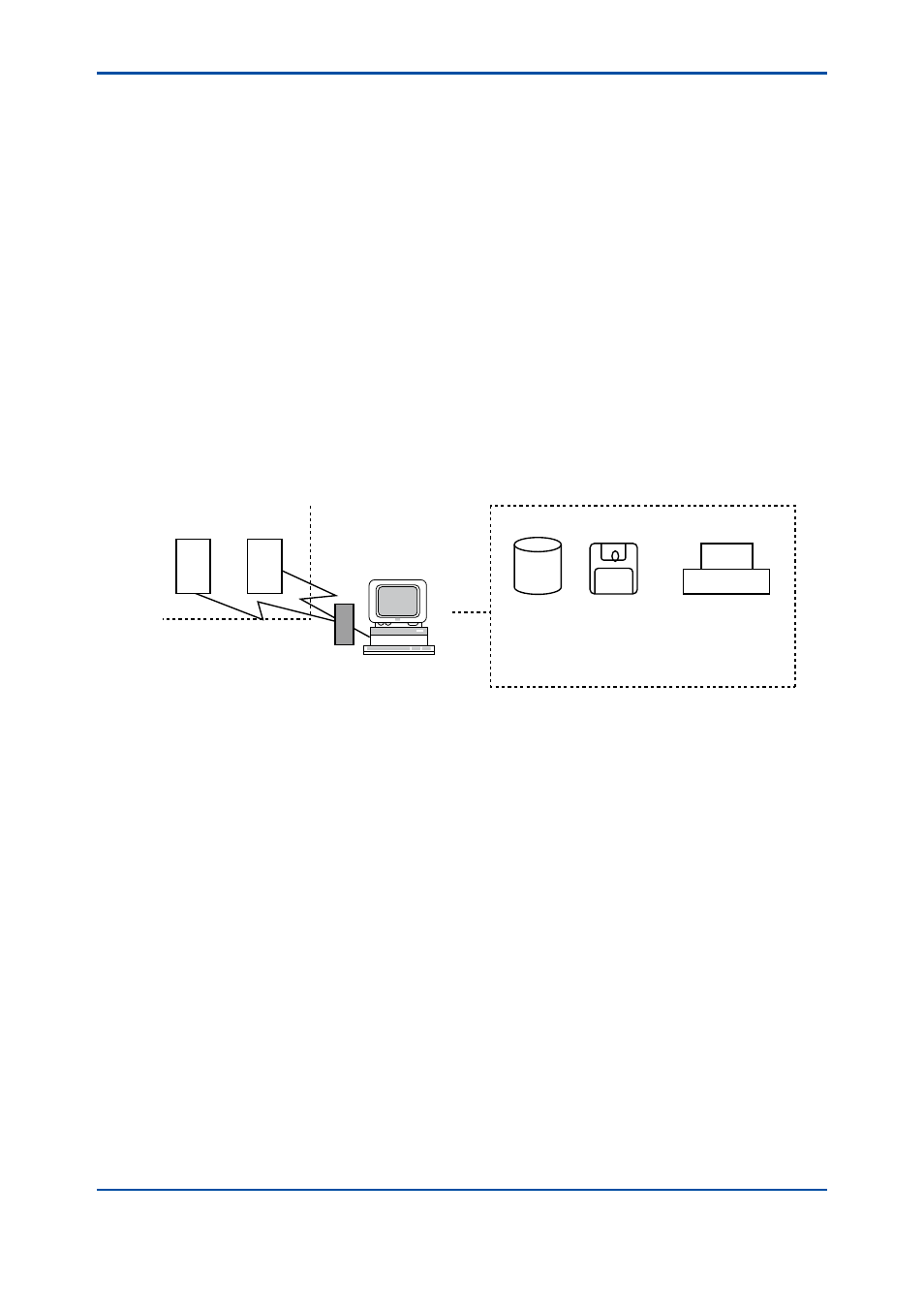

This chapter gives an overview of the Engineering Terminal, as well as the basic facts that

you need to know before operating the Engineering Terminal.

1.1

Engineering Terminal

Before operating the Engineering Terminal, take a look at what kind of software the Engineering

Terminal contains.

n

Engineering Terminal

The ASET Engineering Terminal is software that is intended for collectively maintaining and

monitoring analyzers from a personal computer. It links an analyzer server connected to multiple

units of GC1000 Mark II and ASIU’s (hereafter called “analyzers”) to a personal computer via a

communication link (Ethernet). Moreover, ASET can also be run on a PC serving as the analyzer

server.

An overview of the Engineering Terminal follows.

F1-1-1.ai

•••••

[Field]

Analyzer

GC1000 markII

Analyzer

GC8000

[Instrument room/office]

Engineering Terminal

Hub

Maintenance and monitoring of analyzers

Disk

Printer

• Saving and reading of

chromatogram and the

results of analysis

• Reading and writing of

setting parameters

• Printing the

chromatogram and

results of analysis

n

Engineering Terminal Features

The Engineering Terminal has the following features:

l

Collective control of up to 64 analyzers

You can control up to 64 analyzers collectively from a single ASET via an analyzer server.

Moreover, up to 240 analyzers can be connected to the analyzer bus. By using multiple ASETs to

control the analyzers in blocks, you can control all 240 analyzers.

l

Continuous monitoring for extended periods

The analyzer server continuously saves data (chromatograms, analyzed values, and setting

parameters) from the analyzers connected via the network. The ASET can call up continuous

data stored in the analyzer server and display it, enabling you to perform continuous monitoring

over extended periods.

l

Data transfer using Ethernet communication

Using Ethernet, the large volumes of data stored in the analyzer server can be uploaded and

downloaded, for each analyzer at a time, at the rate of 100 Mbps. ASET uses the standard file

transfer protocol FTP, thus significantly improving the reliability of data transfer.

5th Edition : Nov. 16, 2011-00