Chapter 1. setting up – IAI America S-SEL-E User Manual

Page 15

Page 13

Chapter 1. Setting Up

7

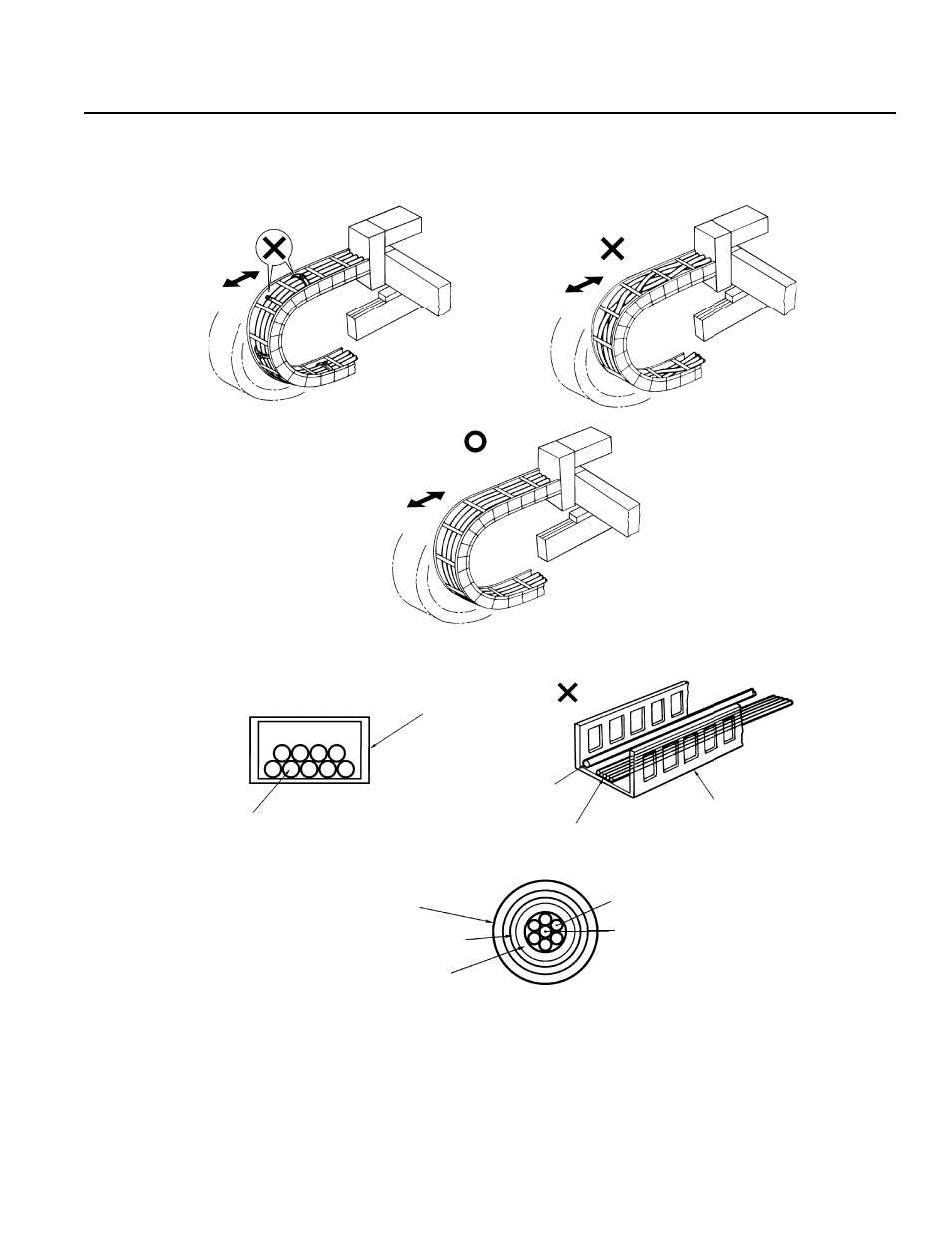

If placing cable in a cableveyor or flexible tube, make sure it does not twist around. Also, make sure the cables have some

freedom of movement and are not bunched up (cable should not project out at bending points).

8

The amount of cable placed inside a cableveyor should

be about 60% of the space capacity of the cableveyor.

9

Do not mix the signal line with a high voltage circuit.

Power supply circuit

10

In a case where the cable will be subject to forced bending, always use robot cable.

Absorption material

(when the cable bends

and there is pressure

from the outside signal

line, this absorbs the in-

ner and outer difference)

Signal line

(flat cable, etc.)

* When to use Robot Cable

When assembling two or three axes and connecting cable to the moving parts, bending weight will be repeatedly applied to the

base of the cable. In this case, the cable core is very likely to snap. To prevent this from happening, we strongly recommend the

use of robot cable which has greatly improved capacity to withstand bending.

[Standard structure]

Varies according to

manufacturer and type

Outer covering

Duct

Signal line (copper + tin)

Shield

Protective layer

Cable

Cableveyor