Flow chart, Appendixes, Application examples • automated test station – Rockwell Automation 1398-PDM-xxx IQ Master Version 3.2.4 for IA-2000 and IQ-5000 Positioning Drive Modules, IQ-55 User Manual

Page 427

Application Examples • Automated Test Station

405

Publication 1398-PM601A-EN-P — October 2000

APPENDIXES

Output 2 is connected to a light to indicate the part failed the test. It may also be used to fire a solenoid

that moves a gate or conveyor to deflect the part to the proper location for rework or scrap.

Output 3 - Ready

Output 3 is used to tell the operator that the previous test is complete and to load a new part.

Output 4 - Error

Output 4 can be used to indicate an error in the test setup.

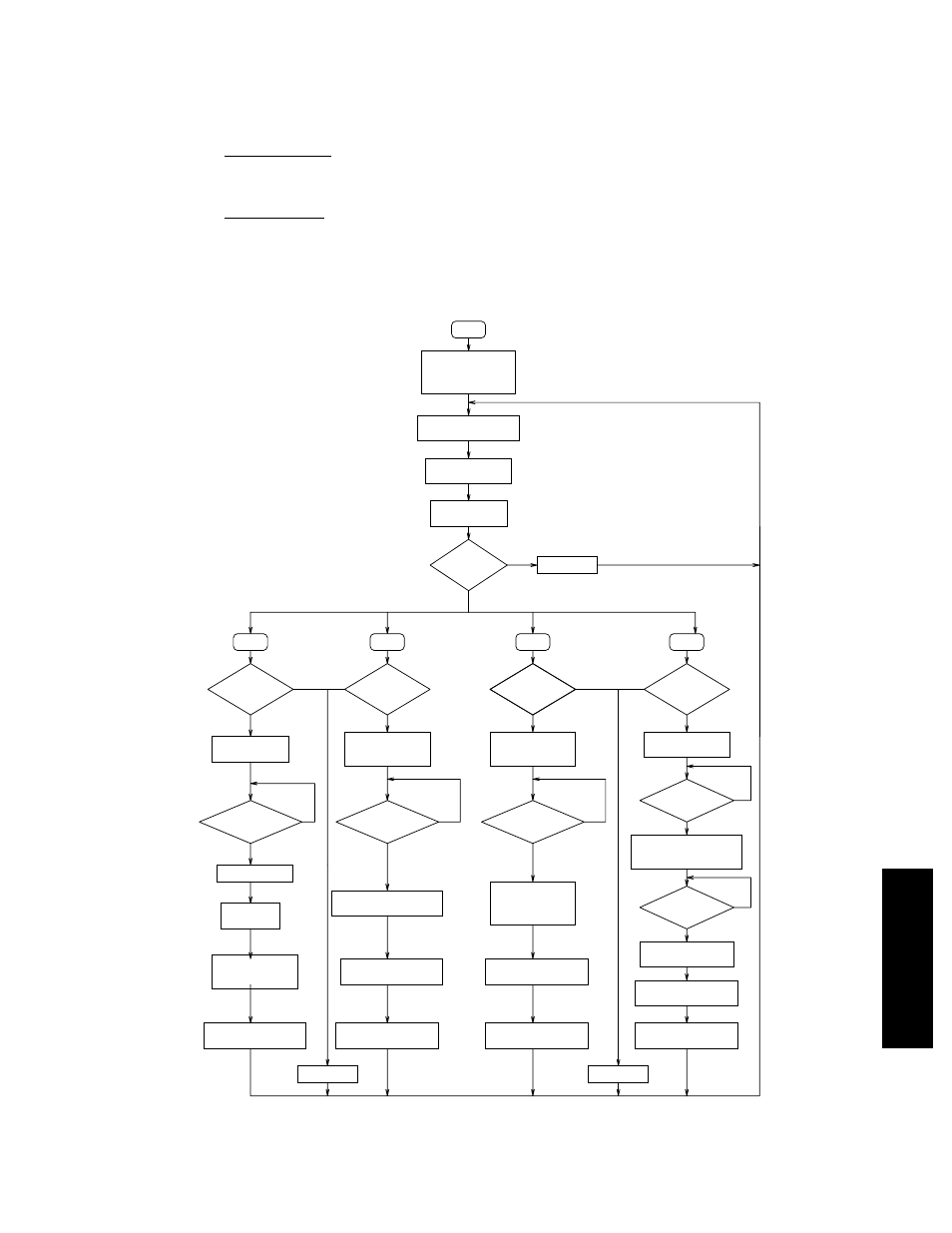

Flow Chart

VALID TEST

NUMBER?

SETUP ERROR

TEST 3

SET CURRENT LIMIT;

START TIMER;

COMMAND MOTION

TEST 2

TEST=2

VALID TEST

PARAMETERS?

YES

TEST=1

TEST 1

VALID TEST

PARAMETERS?

YES

NO

VALID TEST

PARAMETERS?

YES

ALL OUTPUTS OFF;

ENABLE

SET PASS /FAIL OUTPUT;

SET TEST COMPLETE FLAG

SET PASS /FAIL OUTPUT;

SET TEST COMPLETE FLAG

YES

SET PASS /FAIL OUTPUT;

SET TEST COMPLETE FLAG

TIMER COMPLETE?

SET CURRENT LIMIT;

START TIMER;

COMMAND MOTION

STOP MOTION;

DISABLE

TIMER COMPLETE?

START TIMER;

MOVE TO VELOCITY

NO

YES

YES

MEASURE CURRENT

NO

DISABLE;

RESTORE CURRENT LIMIT

DISABLE;

RESTORE CURRENT LIMIT

MEASURE VELOCITY;

STOP MOTION;

COMPARE VELOCITY

TO MAXIMUM

SET CURRENT LIMIT;

MOVE FORWARD

VALID TEST

PARAMETERS?

YES

PART ENGAGED?

NO

MEASURE DEFLECTION;

COMPARE TO LIMITS

SET PASS /FAIL OUTPUT;

SET TEST COMPLETE FLAG

DISABLE;

RESTORE CURRENT LIMIT

NO

SETUP ERROR

VALID TEST

PARAMETERS?

SETUP ERROR

SET READY OUTPUT;

WAIT FOR START

WAIT FOR HOST TO READ

PREVIOUS DATA

DISABLE;

CLEAR OUTPUTS;

SCANNED EVENTS;

INITIALIZE VARIABLES

YES

NO

NO

NO

YES

YES

START

MEASURE PART MOVEMENT;

COMPARE TO MAXIMUM

CALCULATE TORQUE;

COMPARE TO TEST

TOLERANCES

CAPTURE POSITION;

CLEAR FOLLOWING ERROR;

MOVE REVERSE

TEST 4

TEST=4

TEST=3

PART ENGAGED?

NO

TIMER COMPLETE?

NO