Rockwell Automation 7000A PowerFlex Medium Voltage Drive (A-Frame) - Classic Control User Manual

Page 461

Troubleshooting

7-23

7000 “A” Frame

7000A-UM150F-EN-P – June 2013

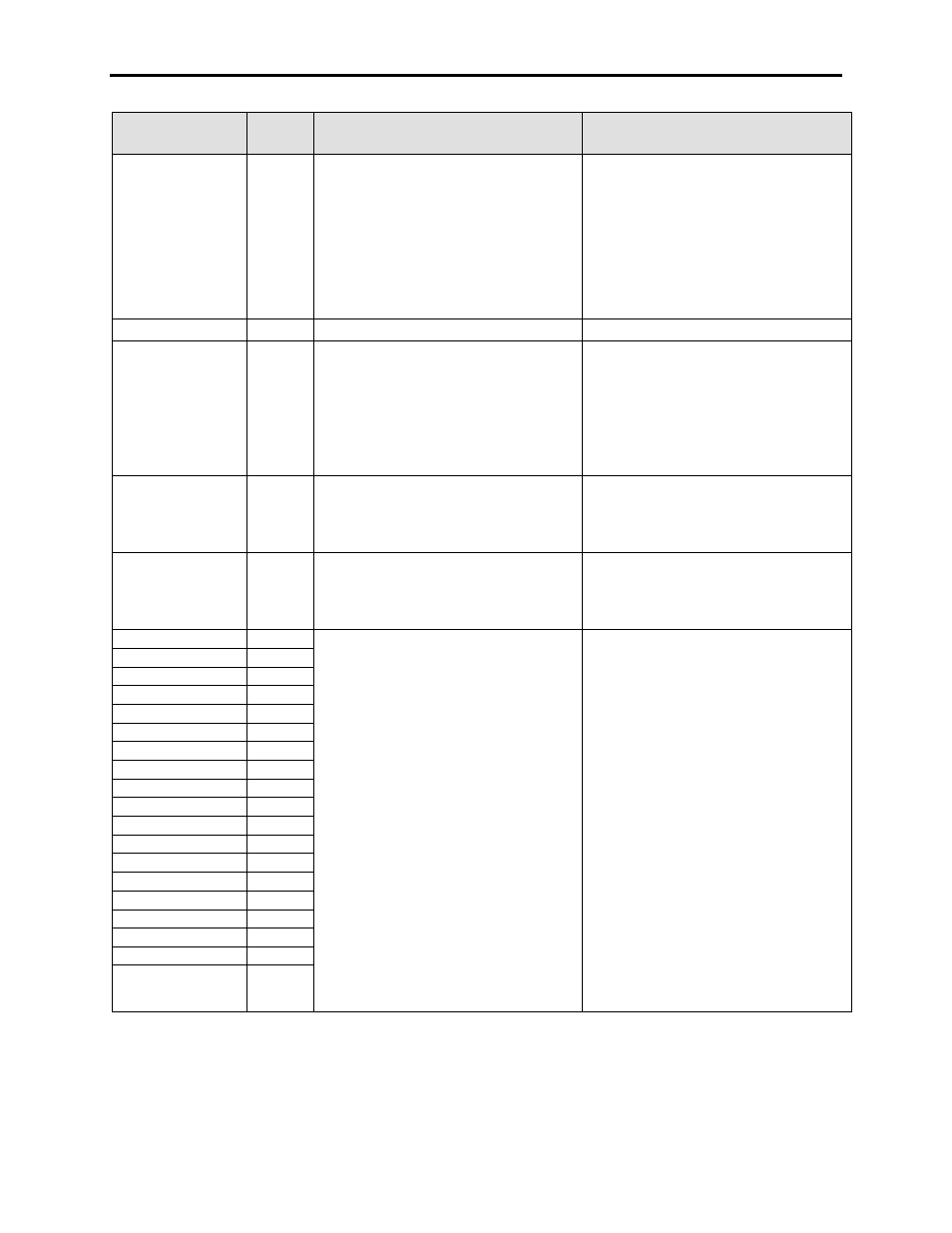

FAULT

MESSAGE

FAULT

CODE

DESCRIPTION

RECOMMENDED ACTIONS

Sync Xfer Failed

75

A Synchronous Transfer was not completed

in the time specified in Synchronous

Transfer Time (P230) and the drive has

faulted. This fault will only occur if the

parameter Sync Xfer Option (P419) is

configured as Enable Fault. If the

parameter is set as Enable Warn, the drive

will go back to last speed command and

issue a warning.

– Instability at Synchronous Speed - Check

for stability of the synchronous transfer

process/ speed regulator

– Load can not reach Synchronous Speed

– Check load conditions for torque limit

or low alpha line (low line voltage)

– Consult factory for review of

synchronous transfer parameters

Tach Loss F

42

Tach Loss fault

– Check the tach feedback

Temp Feedback Ls

(C-Frame only)

232

This fault occurs only if the drive is not

running. The drive has detected missing

temperature feedback from the cooling

system. A missing sensor can be

interpreted as either 0°C or over 100°C, and

both are unrealistic values, so it is

considered a Feedback Loss.

– Verify sensor is completely seated

properly on TFB.

– Measure sensor resistance.

– Verify Fiber Optics are properly seated

on TFB

– Verify the TFB has power

– Replace if necessary.

Terminal USART

241

CIB Hardware Fault

– CIB Hardware Problem

– Cycle control Power to the drive, and if

the problem still exists the board should

be replaced

XIO Interface

244

CIB Hardware Fault

– CIB Hardware Problem

– Cycle control Power to the drive, and if

the problem still exists the board should

be replaced

U1A Device Flt

117

INVERTER SGCT FAULT

This fault will only occur during the initial

contactor closure and the diagnostic

sequence after a start command. The

inverter monitors the state of the feedback

before a gate pulse is given, and monitors

the feedback after a gate pulse has been

sent. The SGCT has smart diagnostics, so

the feedback may indicate short before

firing, and if the pulse is received and the

device is really shorted, the diagnostic will

toggle the feedback to let you know the

problem is with the device, or the power

supply for that device.

The firmware now completes a diagnostics

sequence immediately after any drive reset,

with the goal of detecting faults before any

destructive action is taken from the next

action

– Complete a resistance check per the

instructions in the manual

– NOTE: SGCTs may not have completely

shorted, and still could read in the kΩ

range – Any devices with low suspect

readings should be changed

– Check the LED status of the SCGT gate

driver card for abnormal readings

– Complete a Gating Test mode check on

the devices

– Verify the associated 20V power supply

is powered and active

– Verify all the power connections to the

SCGT firing card are seated properly

U1B Device Flt

123

U1C Device Flt

480

U4A Device Flt

120

U4B Device Flt

126

U4C Device Flt

483

V3A Device Flt

119

V3B Device Flt

125

V3C Device Flt

482

V6A Device Flt

122

V6B Device Flt

128

V6C Device Flt

485

W2A Device Flt

118

W2B Device Flt

124

W2C Device Flt

481

W5A Device Flt

121

W5B Device Flt

127

W5C Device Flt

484