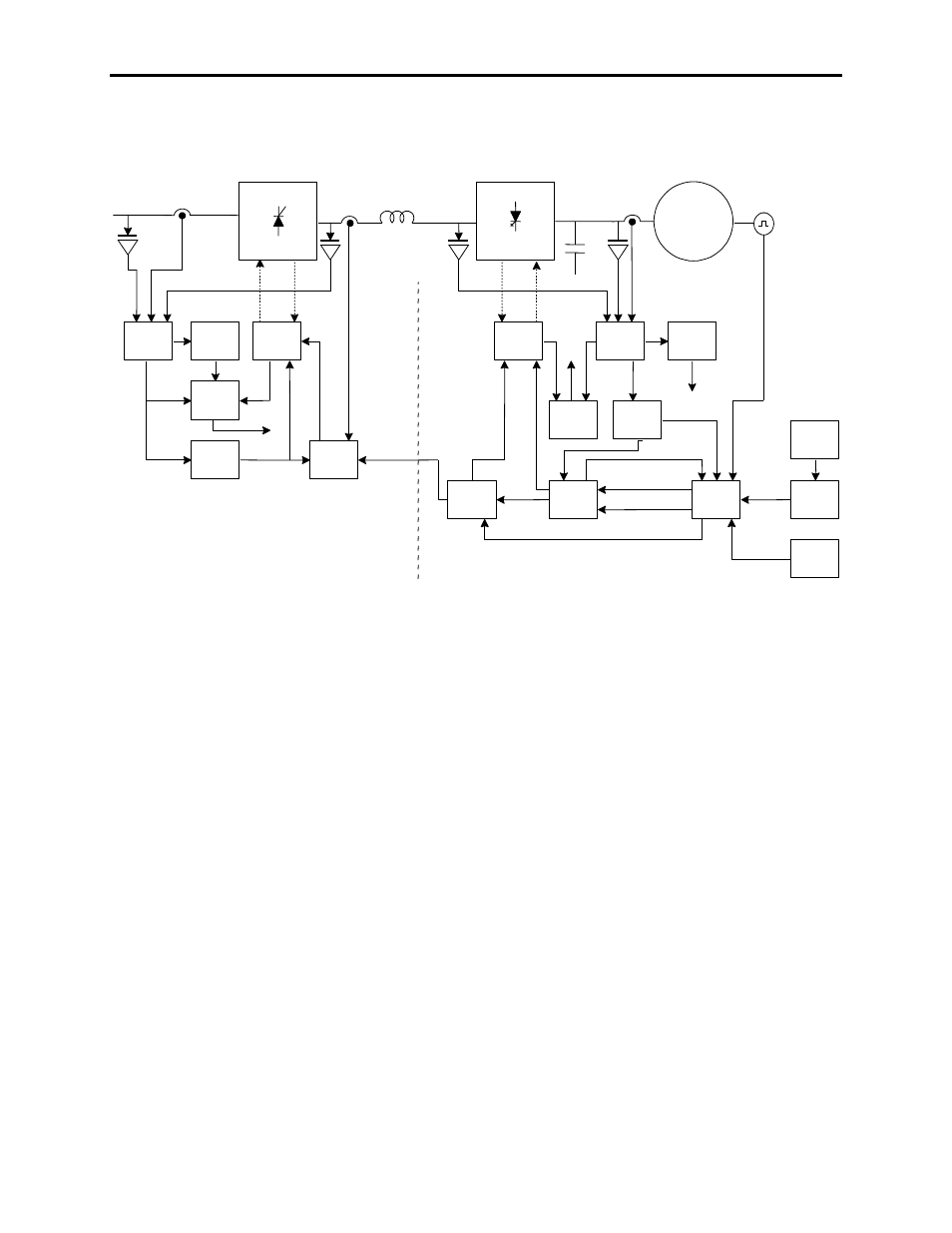

Control overview, Direct vector control, 18 overview of drive – Rockwell Automation 7000A PowerFlex Medium Voltage Drive (A-Frame) - Classic Control User Manual

Page 36

1-18

Overview of Drive

7000A-UM150F-EN-P – June 2013

7000 “A” Frame

Control Overview

Line

Converter

Feedback

Line

Converter

Protection

(HW)

Line gating

and

diagnostic

feedback

Line

Converter

Protection

Line

Side

Control

Machine

Side

Control

Line Converter

Faults

Line

Synch

Current

Control

Li

ne

c

on

verte

r fi

ring

a

ng

le

Idc ref.

Ref.

Current and

phase shift

calculator

Flux

Control

Mag.Current

command

Torque current command

Speed

Control

Torque

Speed Feedback

Machine

Converter

Protection

(SW)

Motor

Model

Synch.

Transfer

Skip Speed

and Speed

Ramp

Speed

Command

Speed Ref.

Tac

h. Fe

ed

ba

ck

Motor

Machine

Converter

Protection

(HW)

Machine

Converter

Feedback

Machine

gating and

diagnostic

feedback

Faults

Motor fil. Cap.

Machine Converter

DC Link

Inductor

M

ac

hi

ne

c

on

verte

r

fi

ring

a

ng

le

Sy

nc

. a

ng

le

Fau

lts

Flux

Figure 1.7 – PowerFlex 7000 “A” Frame Function Block Diagram

Direct Vector Control

The method of control in the PowerFlex 7000 “A” Frame medium

voltage AC drive is called sensorless direct vector control, meaning

that the stator current is divided into torque producing and flux

producing components, allowing the motor torque to be changed

quickly without affecting motor flux. This method of control is used

without tachometer feedback for applications requiring continuous

operation above 6 Hertz and less than 100% starting torque.

Full vector control can also be achieved with tachometer feedback

for applications requiring continuous operation down to 0.2 Hertz

with up to 150% starting torque. Vector control offers superior

performance over volts/hertz type drives. The speed bandwidth

range is 5-25 radians per second, while the torque bandwidth range is

15-50 radians per second.