2 maintaining the fiber-optic dcs-net network, 2 maintaining the fiberćoptic dcsćnet network, 3 maintaining the coaxial cable system – Rockwell Automation 57C570 AutoMax PC3000 User Manual User Manual

Page 236: 4 inspecting the cable system

21Ć4

P

/

S

P

R

O

C

E

S

S

O

R

N

E

T

W

O

R

K

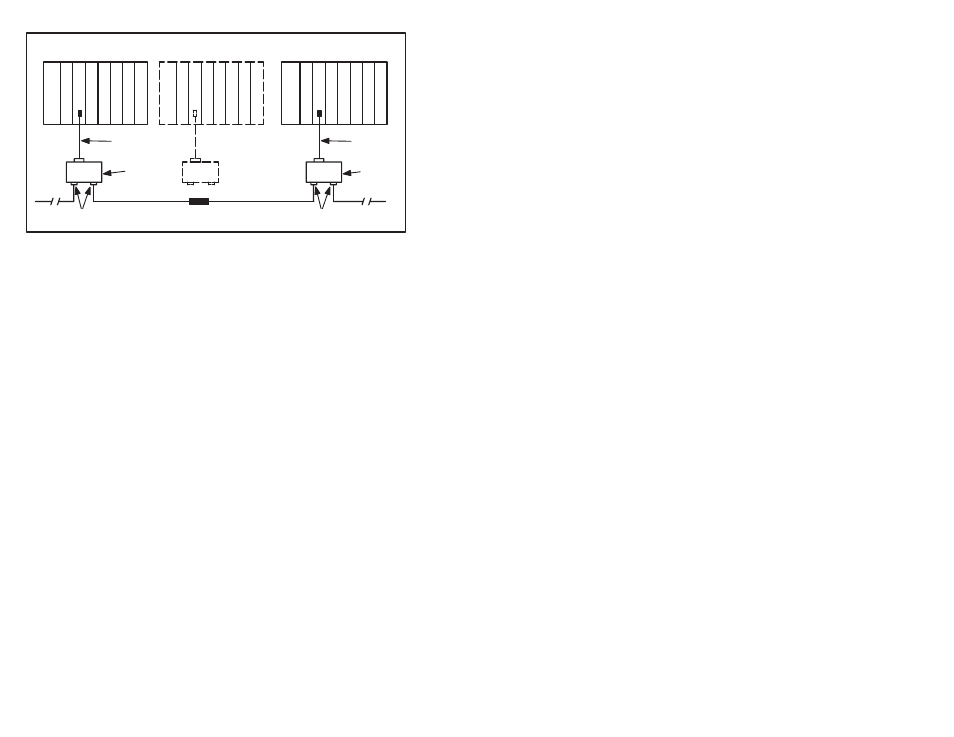

PASSIVE

TAP

DROP

CABLE

DISCONNECTED DROP

BNC CONNECTORS

P

/

S

P

R

O

C

E

S

S

O

R

N

E

T

W

O

R

K

PASSIVE

TAP

DROP

CABLE

BNC CONNECTORS

SPLICE

Figure 21.4 Ć Disconnecting an Intermediate Drop from the Network Cable System

Step 4.

Resume network operation.

21.1.3 Maintaining the Coaxial Cable System

Even if the installation is done properly, the AutoMax network may

still experience some unexpected downtime. This may be due to

gradual degradation of the cable system components or changes in

the environmental conditions along the cable path. Because of this,

some limited preventive maintenance is required.

Keep the network cable system documentation upĆtoĆdate with all

changes made to the network configuration during the life of the

network.

When old equipment is relocated or new equipment is installed, new

sources of heat, electrical noise, hazardous chemicals, and other

changes in the network cable system environment may occur.

Evaluate the effect these changes have on the performance of the

network. If necessary, take corrective action such as rerouting

certain AutoMax network cable segments and adding shielding to

the cable system components.

21.1.4 Inspecting the Cable System

Inspect the AutoMax network cable system periodically for damage,

shorts, and discontinuity. To perform these tests, use the appropriate

time domain reflectometer (TDR) for the cable length. TDRs can be

also used to perform cable testing during the installation or to locate

a possible cable fault during troubleshooting. All tests should be

properly documented.

21.2

Maintaining the FiberĆOptic DCSĆNET

Network

Refer to this section for information about maintaining the fiberĆoptic

DCSĆNET network.