5 testing cable segments – Rockwell Automation 57C570 AutoMax PC3000 User Manual User Manual

Page 109

7Ć11

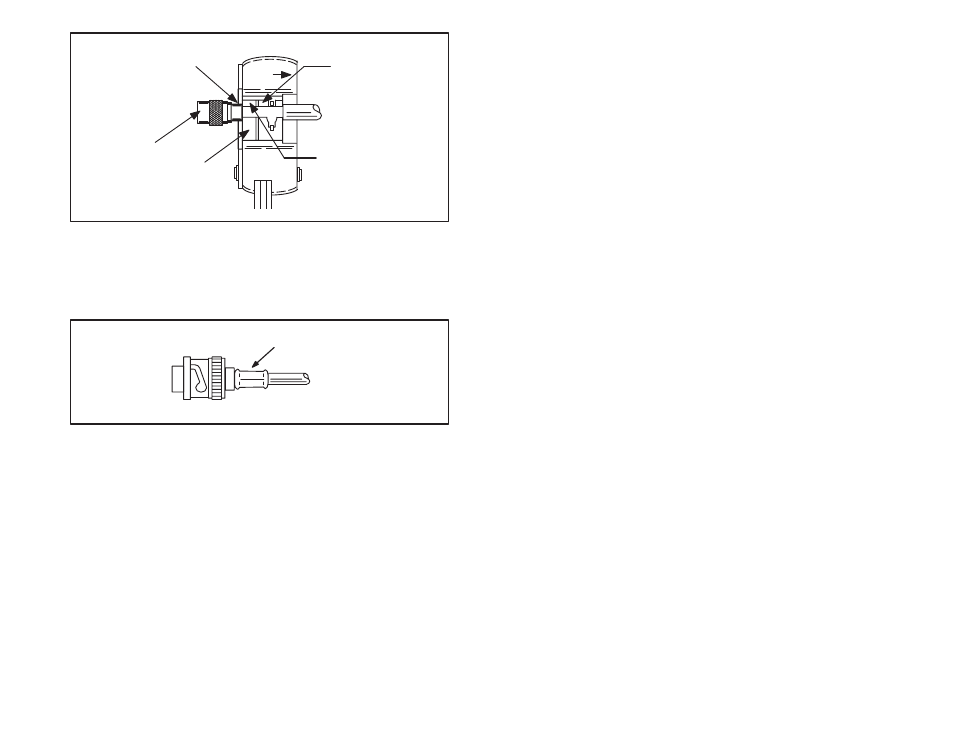

CABLE

SIDE

PLACE CONNECTOR

AND FERRULE,

ASSEMBLED ON

CABLE, IN UPPER

CRIMPING DIE

SHOULDER ON

CONNECTOR RESTS

AGAINST DIE

CONNECTOR

BRAID

CRIMP

LOCATE CONNECTOR

IN TOOL EXACTLY

AS SHOWN

Figure 7.18 Ć Place Connector Assembly in Tool

Step 13. Close the handles until the ratchet releases to complete

the crimp.

Step 14. Remove the crimped assembly from the crimping dies.

The connector is now attached to the coax cable, as

shown in figure 7.19.

CRIMPED FERRULE

Figure 7.19 Ć Connector Attached to RGĆ11/U Cable

7.5

Testing Cable Segments

Once a cable segment has been terminated with a connector on

each end, visually inspect the connector for loose connections,

nicked insulation, or loose strands from the braid that might cause a

poor connection or short. The center contact should be straight and

centered inside the connector dielectric. Be sure that the center

contact is inserted deep enough into the connector body. The tip of

the center contact should be about even with the end of the

connector dielectric. Be sure the ferrule is crimped tightly against

the body of the connector and that the shield braid wire does not

protrude from the ferrule. Check the cable's mechanical connections

by grasping the outer conductor connector in one hand and the

coax jacket in the other. Pull firmly. The connectors should hold.