External shunt modules – Rockwell Automation 2094-EN02D-M01-Sx Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User Manual User Manual

Page 51

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

51

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

Chapter 2

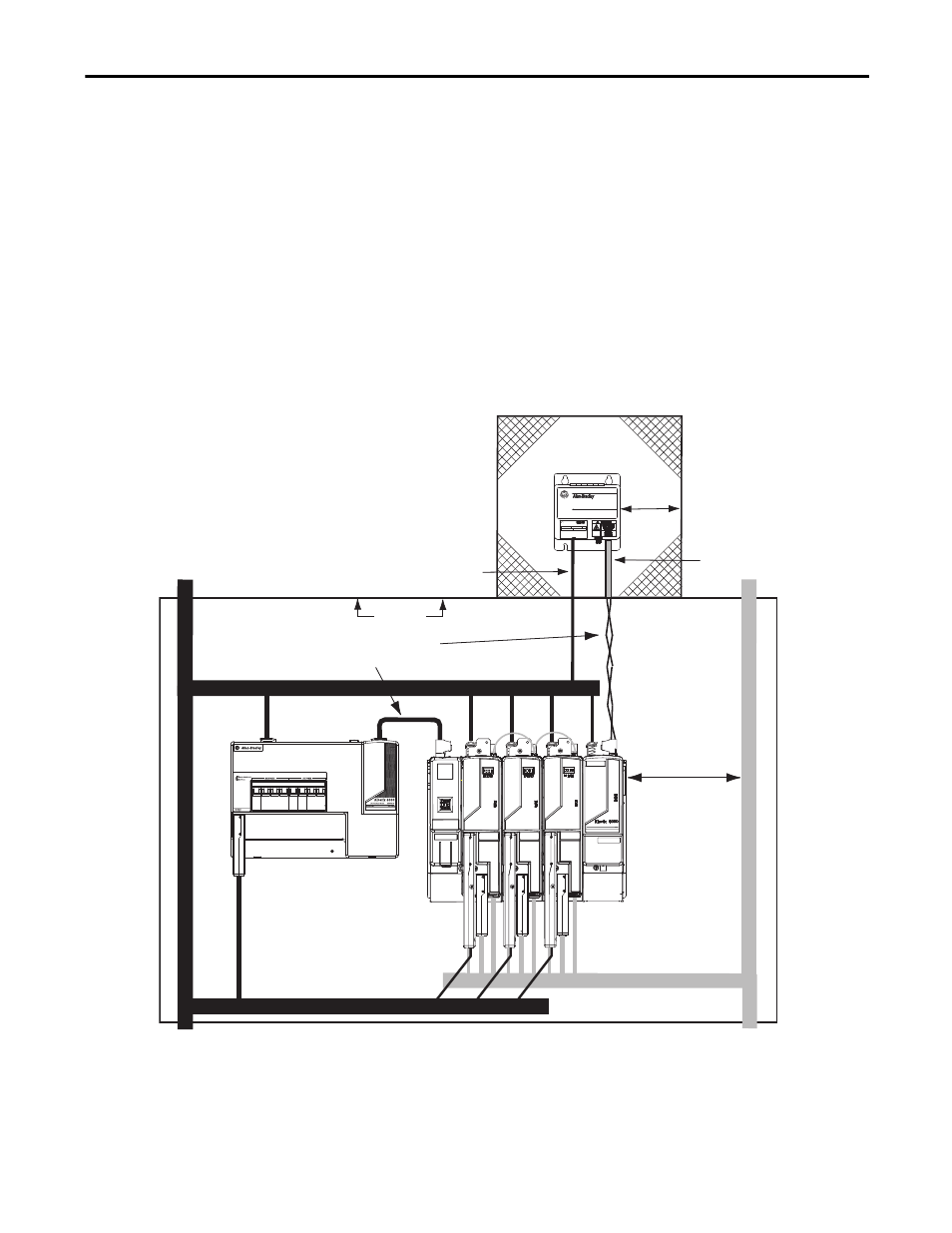

External Shunt Modules

Observe these guidelines when mounting your external shunt module outside the

enclosure:

• Mount circuit components and wiring in the very dirty zone or in an

external shielded enclosure. Run shunt power and fan wiring inside metal

conduit to minimize the effects of EMI and RFI.

• Mount resistors (other than metal-clad) in a shielded and ventilated

enclosure outside the cabinet.

• Keep unshielded wiring as short as possible. Keep shunt wiring as flat to

the cabinet as possible.

• Route thermal switch and fan wires separate from shunt power.

Figure 22 - External Shunt Module Outside the Enclosure

C

D

D

D

D

D

VD

C

VD

D

1394 Digital Servo Controller

300W Shunt Module

BULLETIN 1394 300W SHUNT MODULE

ALLEN-BRADLEY

FOR USE WITH 1394-SJT22-X SYSTEM MODULE

CAT.

PART

SER.

INPUT DC

INPUT AC

FOR FUSE REPLACEMENT USE:

BUSSMAN CAT. NO.

R

Line Interface Module

Kinetix 6200 or

Kinetix 6500 System

Dirty Wireway

Clean Wireway

Motor Power Cables

Very Dirty Connections Segregated

(not in wireway)

Customer-supplied

Metal Enclosure

150 mm (6.0 in.)

clearance (min) on all four

sides of the shunt module.

Enclosure

2094-BSP2

Shunt Module

Metal Conduit

(where required

by local code)

Shunt thermal Switch and Fan Wires (when present)

No sensitive

equipment within

150 mm (6.0 in.).

Clean I/O, Feedback, and

Ethernet Cables

Dirty I/O and

Safety Cables

Shunt Power Wiring Methods:

Twisted pair in conduit (1st choice).

Shielded twisted pair (2nd choice).

Twisted pair, two twists per foot (min) (3rd choice).