Bonding multiple subpanels – Rockwell Automation 2094-EN02D-M01-Sx Kinetix 6200 and Kinetix 6500 Modular Multi-axis Servo Drives User Manual User Manual

Page 38

38

Rockwell Automation Publication 2094-UM002E-EN-P - May 2012

Chapter 2

Planning the Kinetix 6200 and Kinetix 6500 Drive System Installation

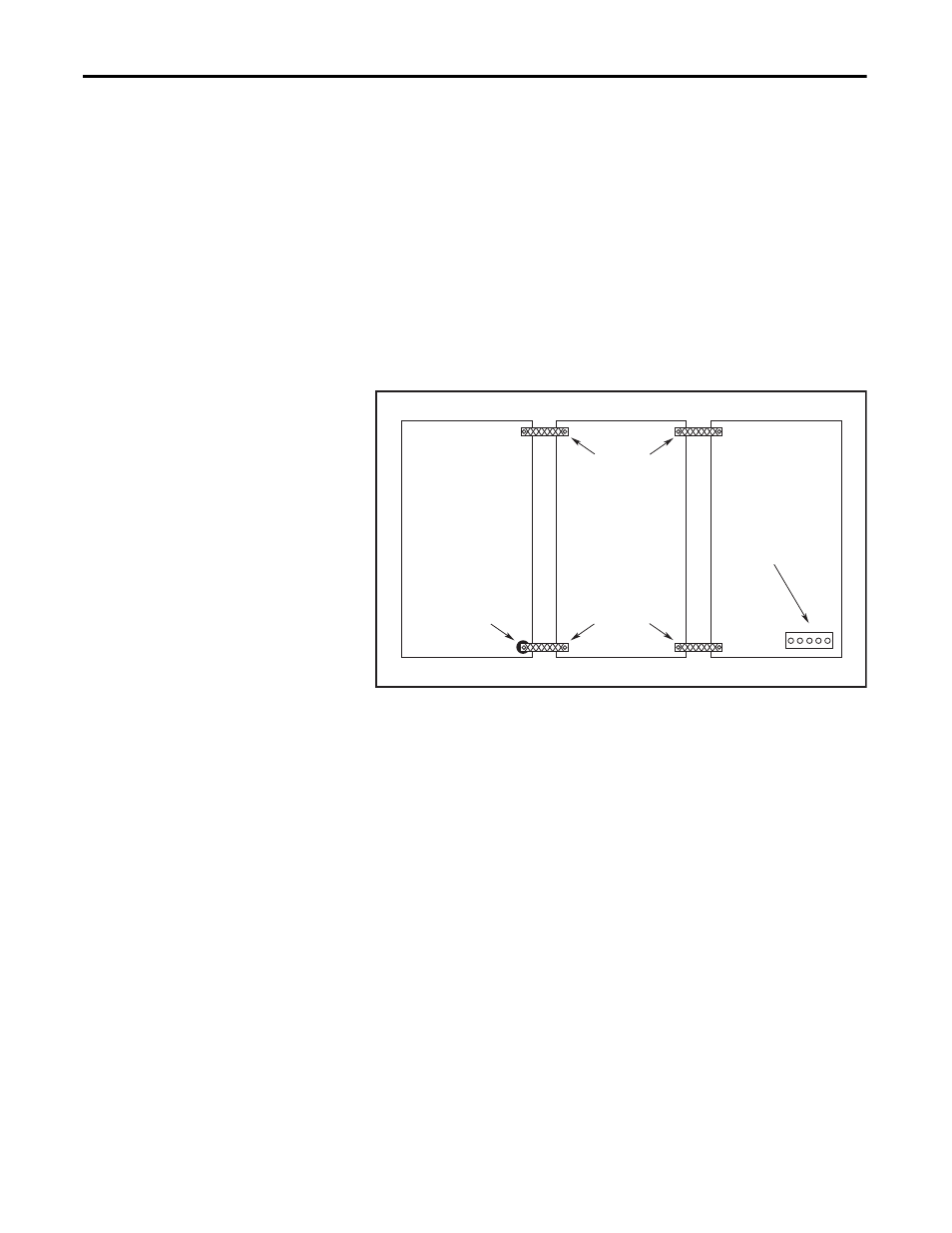

Bonding Multiple Subpanels

Bonding multiple subpanels creates a common low impedance exit path for the

high frequency energy inside the cabinet. Subpanels that are not bonded together

may not share a common low impedance path. This difference in impedance may

affect networks and other devices that span multiple panels.

• Bond the top and bottom of each subpanel to the cabinet by using

25.4 mm (1.0 in.) by 6.35 mm (0.25 in.) wire braid. As a rule, the wider

and shorter the braid is, the better the bond.

• Scrape the paint from around each fastener to maximize metal-to-metal

contact.

Figure 12 - Multiple Subpanels and Cabinet Recommendations

Wire Braid

25.4 mm (1.0 in.) by

6.35 mm (0.25 in.)

Paint removed

from cabinet.

Cabinet ground bus

bonded to the subpanel.

Wire Braid

25.4 mm (1.0 in.) by

6.35 mm (0.25 in.)