INFICON HAPSITE ER Chemical Identification System User Manual

Page 481

16 - 5

IP

N 07

4-

47

1-

P1

B

HAPSITE ER Operating Manual

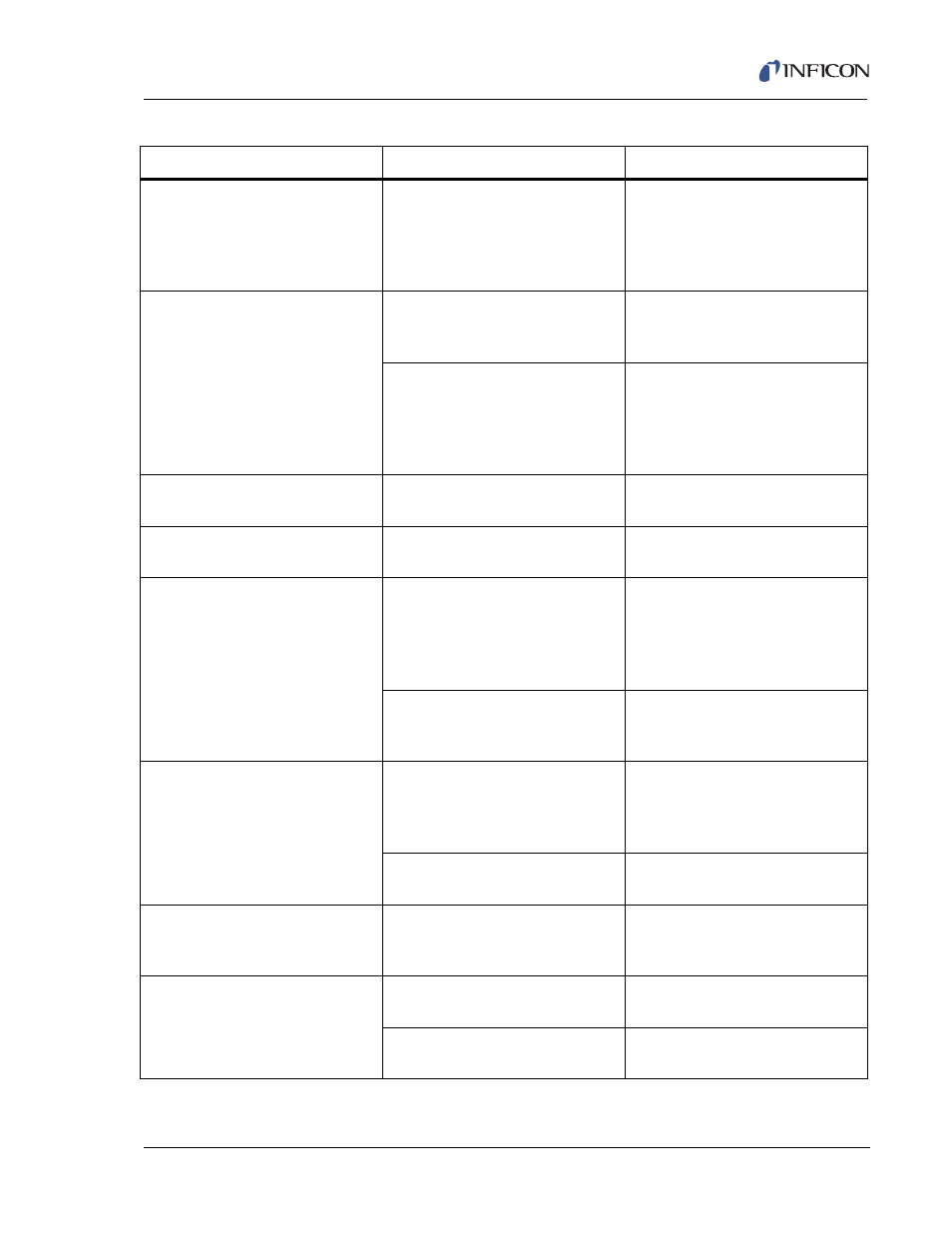

9d. Check turbo speed in Service

Module program, If less then 1480

Hz, Service Module pumps may

need maintenance or the system

may have an air leak.

9d. Contact INFICON (see

10. “Pressure too low to

read” message at user

interfaces.

10a. Pressure is too low to read.

The system has a lower pressure

limit of 1x10

-4

Pa.

10a. Open membrane isolation

valve. This will bring the pressure

to 1-3x10

-3

Pa.

10b. Ion pump has failed to turn

on.

10b. Close and open the

membrane valve a few times. If

this fails to shock the ion pump into

starting. Contact Customer

Support (see

).

11. Sample carrier over from one

run to the next.

11a. Cold spot in the sampling

system.

11a. Check to see if heat zones are

at temperature.

12. Internal Standard in back

ground.

12a. Low pneumatic (carrier gas)

pressure at GC 10-port valve.

12a. Check carrier gas pressure,

and replace canister if low.

13. Temperature zones read 99.8

o

C or higher.

13a. Component in the zone is hot. 13a. There is a problem with the

GCC card and it cannot control the

temperature.

Contact Customer Support (see

13b. Zone is cold.

13b. Sensor could be bad. Contact

Customer Support (see

).

14. Unable to read memory chips

on gas canister.

14a. Poor connections, or

damaged contact.

14a. Try re-seating canister, or try

a known good can. If this fails,

contact Customer Support (see

14b. Processor card failure.

14b. Contact Customer Support

(see

).

15. Water enters system during

decontamination.

15a. Dirt on the gaskets, or

improper seal. Clean gasket and

check seals.

15a. If problem can not be

corrected, contact Customer

Support (see

).

16. Poor Gas Chromatographic

Peaks/ Poor GC sensitivity.

16a. GC column has degraded.

16a. Contact Customer Support

(see

).

16b. Loose connections at sample

loop, concentrator or ferrules.

16b. Check to see if fittings and

ferrules are properly installed.

Table 16-1 Diagnosing Problems - HAPSITE

Symptom

Cause

Remedy