Power and control wiring (cont.) – Rockwell Automation 7000L PowerFlex 7000 Medium Voltage AC Drive C Frame - Marine User Manual

Page 88

2-58

Drive Installation

7000L-UM302B-EN-P – June 2013

7000 “C” Frame - Marine

Encoder Installation Guidelines

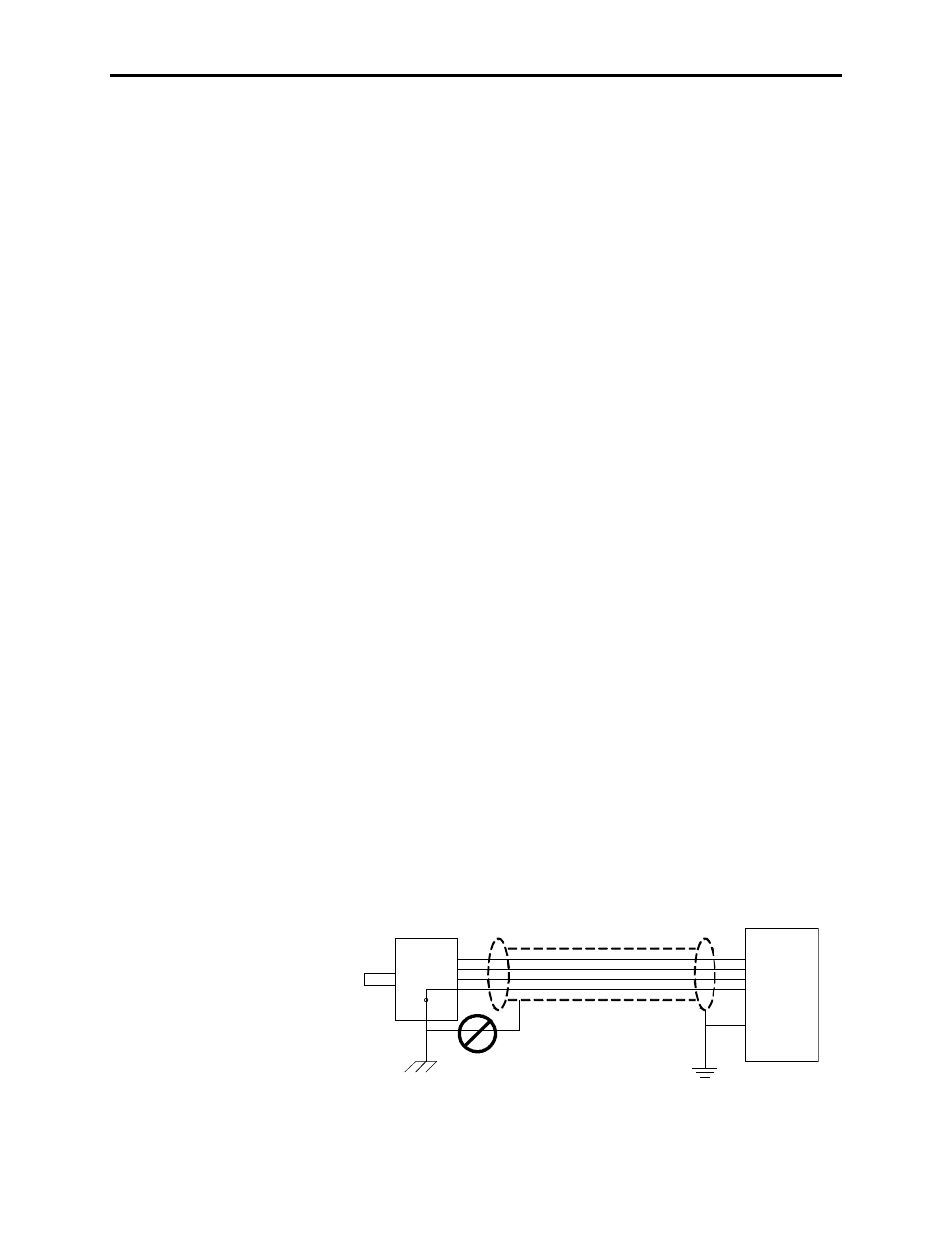

The most frequent problems encountered when transmitting an

encoder‟s signal(s) to the drive are signal distortion and electrical

noise. Either of these problems can result in a gain or loss of encoder

data counts (quadrature encoders) or corrupt positional data (absolute

encoders). Many of these problems can be avoided by applying good

installation and wiring practices. This section is a general guideline

and recommended practices for field installed equipment. It applies

to either encoder board and both quadrature and absolute encoders.

• Protection from Radiated and Conducted Noise

Reasonable care should be taken when connecting and routing power

and signal wiring on a machine or system. Radiated noise from nearby

relays, solenoids, transformers, non linear loads (such as motor drives)

etc. can couple onto signal wires producing undesired pulses. In fact

the encoder itself may induce noise into signal lines run adjacent to it.

To avoid radiated and/or conducted noise, power and signal lines

should be run separately with a minimum distance between them of

at least 75 mm (3 inches). If they have to overlap somewhere in the

system, then the power lines should be run at 90° to the signal lines.

Signal lines should also use twisted pair shielded cable and run in

separate conduit that should be grounded to the building ground.

Encoder wires and shields should maintain continuity throughout,

from the encoder to the drive. Avoid the use of a terminal block in a

junction box. This has the potential of creating radiated noise and

ground loops.

The encoder case must be grounded to the building ground to insure

proper and reliable operation. Most encoders have provision for a

case ground connection through the connector/cable pair if a ground

connection cannot be made through the mounting bracket/machine

ground. DO NOT ground the encoder case through both the

machine and cable wiring. Use low capacitance wires ( ≤ 40pf/ft)

with 100% shield coverage for long cable runs and connect the shield

only at the drive end.

Wrong Shield

Connection

Encoder

Drive

Figure 2.63 – Detail Power Terminal Dimensions

Power and Control Wiring

(cont.)