P stc-2002, Deposition controller y, Hardware setup discussion – INFICON STC-2002 Thin Film Deposition Controller Operating Manual User Manual

Page 31

p STC-2002

DEPOSITION CONTROLLER

y

SECTION 2.XX

e page 29 of 276 ^

chooses the sensors that are part of the multiple sensor group. Since each sensor has a unique parameter

group, programming 2 or more crystals as active automatically invokes an averaging mode. Lost channels

during averaging are handled by menu programmed alternatives (Main Menu/Review SS Maps/Channel

Drop Filter Mask). TBD multiple sensor deposition: averaging multiple, averaging weight, interaction

calibration (among the crystal sensors) . [additive]

Although the STC-2002 cannot control multiple depositions (multiple sources as is the case with

co-deposition), but it can maintain other multiple sources (depending on installed and available sensor

cards) such that one source output is controlled while other source outputs can be maintained at a non-zero

power level. This would provide the ability to precondition other materials that could become activated

(controlled) when the currently controlled source reaches its preset conditions. In other words, multiple

source outputs can be providing some level of output to multiple power supplies while deposition control

can be focused on a single source output (moved) among these. The preconditioning mentioned above

would include the soak phases of the deposition process cycle. The soak phase is (or soak phases are)

characterized by power being maintained at a constant level.

Note soak power levels in deposition cycle

Rise

1

Rise

2

Soak

1

Soak

2

Shutter

Delay

Deposit

Rate

Ramp

Deposit

2

Idle

Ramp

Idle

.

The more imaginative among us might, at this time, see an opportunity here to use the STC-2002 for a co-deposition process (set the

rate for a source output when active, select another source output as active and then allow the non-controlled output to deposit along

with the controlled output deposition). The problem with this scenario is in the shutter control that is linked to the active output

channel. Alternately, the shutter control could be accomplished with an I/O program but it would not control the process like a true co-

deposition unit nor would it have the same co-deposition oriented amenities

.

hardware setup discussion

(for actual installation details see Sections x3 & 4 but please read this section first)

.

necessities: crystal sensor head, osc, bnc cables, vacuum chamber, etc

.

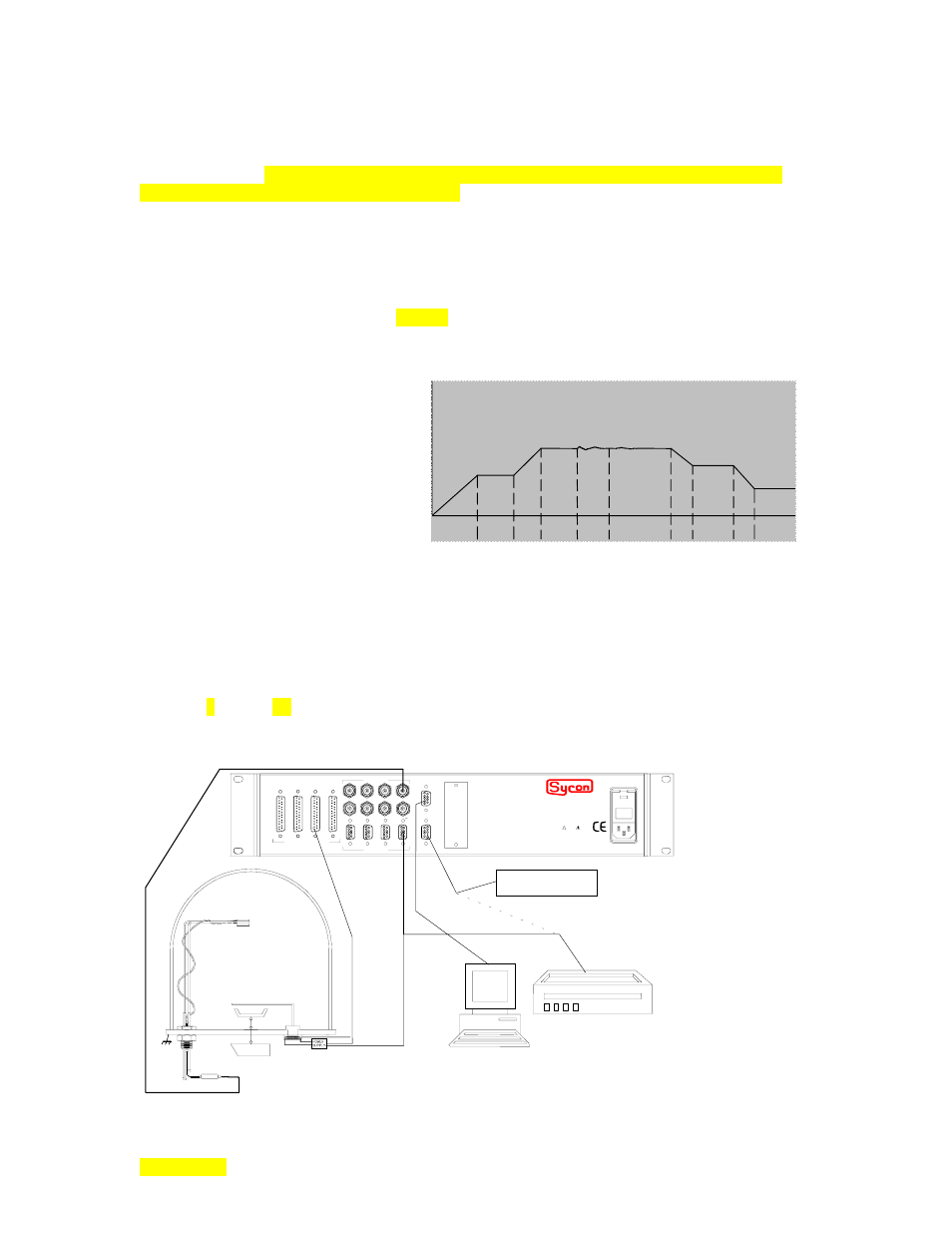

Following is a diagram of a typical evaporator installation. This diagram is repeated and described further

in Section 3 (see fig. 3.7).

NOTE: Chart recorder function through memory module connection uses optional hardware and TBD software.

CRYSTAL SENSOR

SHUTTER

DATA AQUISITION

COMPUTER

CHAMBER

DEPOSITION

SOURCE

OSCILLATOR

WARNING

!

The power cord protective

grounding conductor must be

connected to ground. No user

serviceable parts inside. Refer

servicing to qualified personnel.

FUSE: 2 x 2.00 AMP

QUICK-ACTING (F) 250v

90-264 vac, 50-60 Hz, 230VA MAX

INPUTS / OUTPUTS

SOURCE

SENSORS

I/O 4 1/O 3 I/O 2 I/O 1

COMM OPTION

RS232

MEM

instruments

Memory Module

7 5 3 1

8 6 4 2

CHART RECORDER

8 6 4 2

7 5 3 1