INFICON STC-2002 Thin Film Deposition Controller Operating Manual User Manual

Page 25

p STC-2002

DEPOSITION CONTROLLER

y

SECTION 2.XX

e page 23 of 276 ^

<

< control loop=2-12 >>

simplest case (seq, non-seq / 1 crystal). 1 process, 1 film, 1 material, 1 crystal, 1 deposit

.

Returning to STC-2002 specifics, some additional STC-2002 terminology definitions must now be given.

Beyond sensor information and power supply control voltage, the

STC-2002

also allows the user to define

the other parameters that are critical in the deposition process.

In STC-2002 terminology, a film is defined as a list of user programmable deposition related

parameters (see XXX). Typically, one material deposition is accomplished per film (describes specific:

material, mechanical setup, timing, etc.). The STC-2002 can store up to 99 films (referred to as a film

recipe library). A process is a list of film implementations. Each film implementation is referred to as a

layer (or step in the process). Process layers can use the same film many times or use any combination of

different films (insert figure / see fig. xx).

The STC-2002 has 2 basic process control modes: sequencing mode and non-sequencing mode.

While in either one of these modes, manual mode (manual control of power) may be invoked. In addition,

a test mode can be employed to simulate (w/ simulated rate information) a crystal sensor input while in any

combination of the modes just described. Simply put, the sequencing / non-sequencing mode difference is

that of having or not having a process. Non-sequencing mode does not have a process (or at least nothing

named as such). Non-sequencing mode uses 1 implicit process which can run 1 film. The non-sequencing

mode is easiest to configure (user programs an active film). The sequencing mode is more complicated

only by the additional programming of a process[es] that calls out a film or films.

The STC-2002 retains the non-sequencing mode for historical compatibility and for simple

depositions.

On the subject of films and processes, that which is referred to as active is that which is queued to

be run when the start sequence is initiated. In other words, except for a co-deposition process, only one

film is being deposited at one time and one process (the active process) is calling out that one film in one of

its steps. When a process is run (start key sequence), it uses the single process that was selected as the

active process (on the Main Menu). Likewise, the film that was selected by the active process as the active

film will become the running film. [The non-sequencing mode has only one inherent unspecified process

and films are manually selected to be active. Only the film selected as active will be run (Main Menu in

non seq mode).] Regardless of mode selection, an active process or active film can be edited (modified)

while a process or film is running but only in a limited manner. This prevents potentially dangerous

situations from occurring. The limitations, that is, the parameters that are not changeable while a process

(or film ) is running include the following:

Film parameters: SS Map Select, Pocket Select, Etching Mode.

Map parameters: CH x Start Mode, Source full power, Source out channel, Indexer Sync Mode.

Min ~~~ XTALS

[3 parameters]

(evaluated at start only except for RE-VERIFY key usage).

Process: Film# of current running step, Process length (no step insertion/deletion).<

<

>

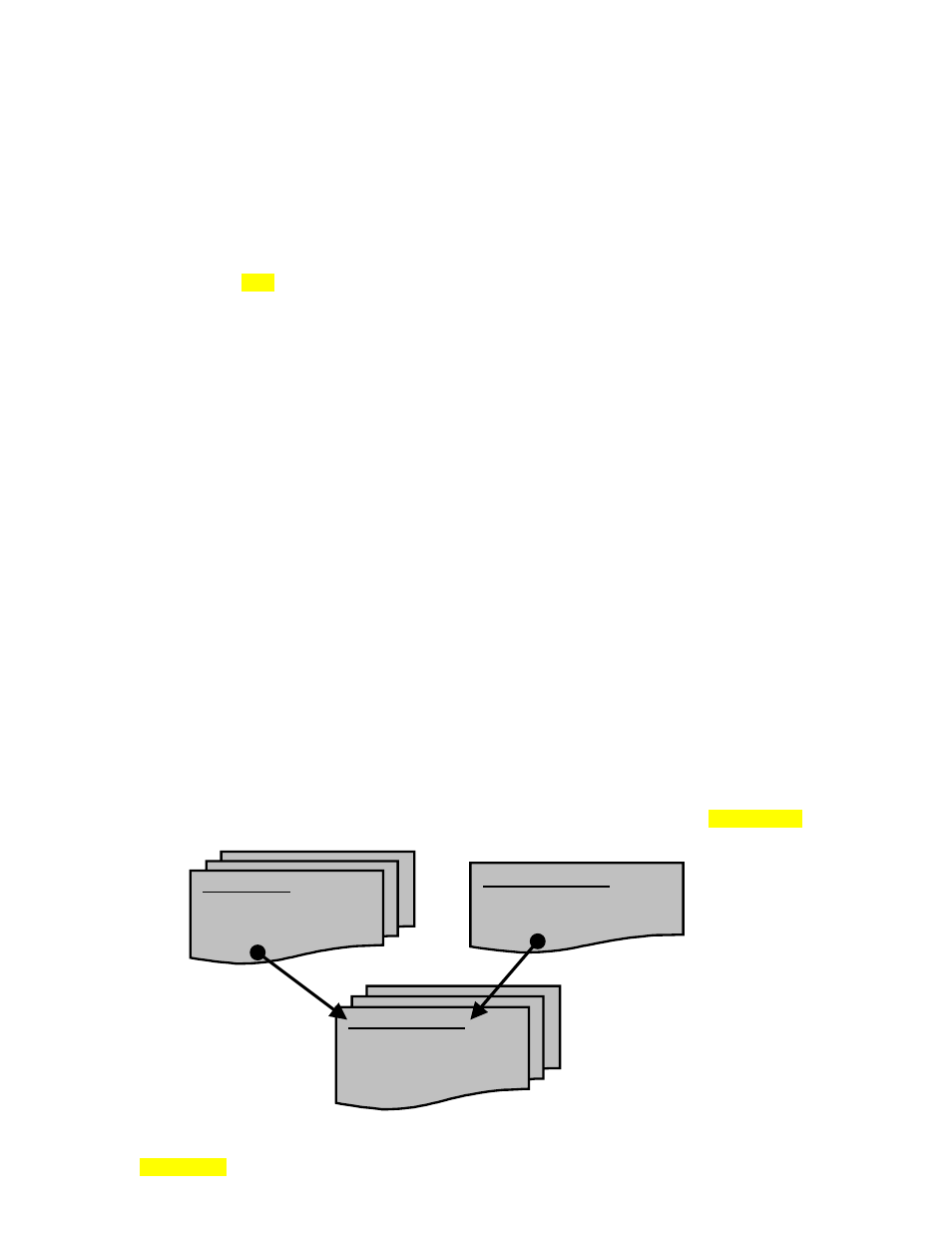

SEQ MODE

1 active process

(process selects 1 or more films)

Up to 9 programmable processes

NON-SEQ MODE

1 implicit active process

(user selects 1 active film)

1 ACTIVE FILM

(up to 99 programmable films)

Film parameters define the

constituent elements of the

deposition