Sensor head installation, P stc-2002, Deposition controller y – INFICON STC-2002 Thin Film Deposition Controller Operating Manual User Manual

Page 137: Electrical connections and descriptions, Figure- : 4.1 head mounting dimensions

p STC-2002

DEPOSITION CONTROLLER

y

SECTION 4.XX

e page 135 of 276 ^

Electrical Connections And Descriptions

SECTION 4.0

Sensor Head Installation

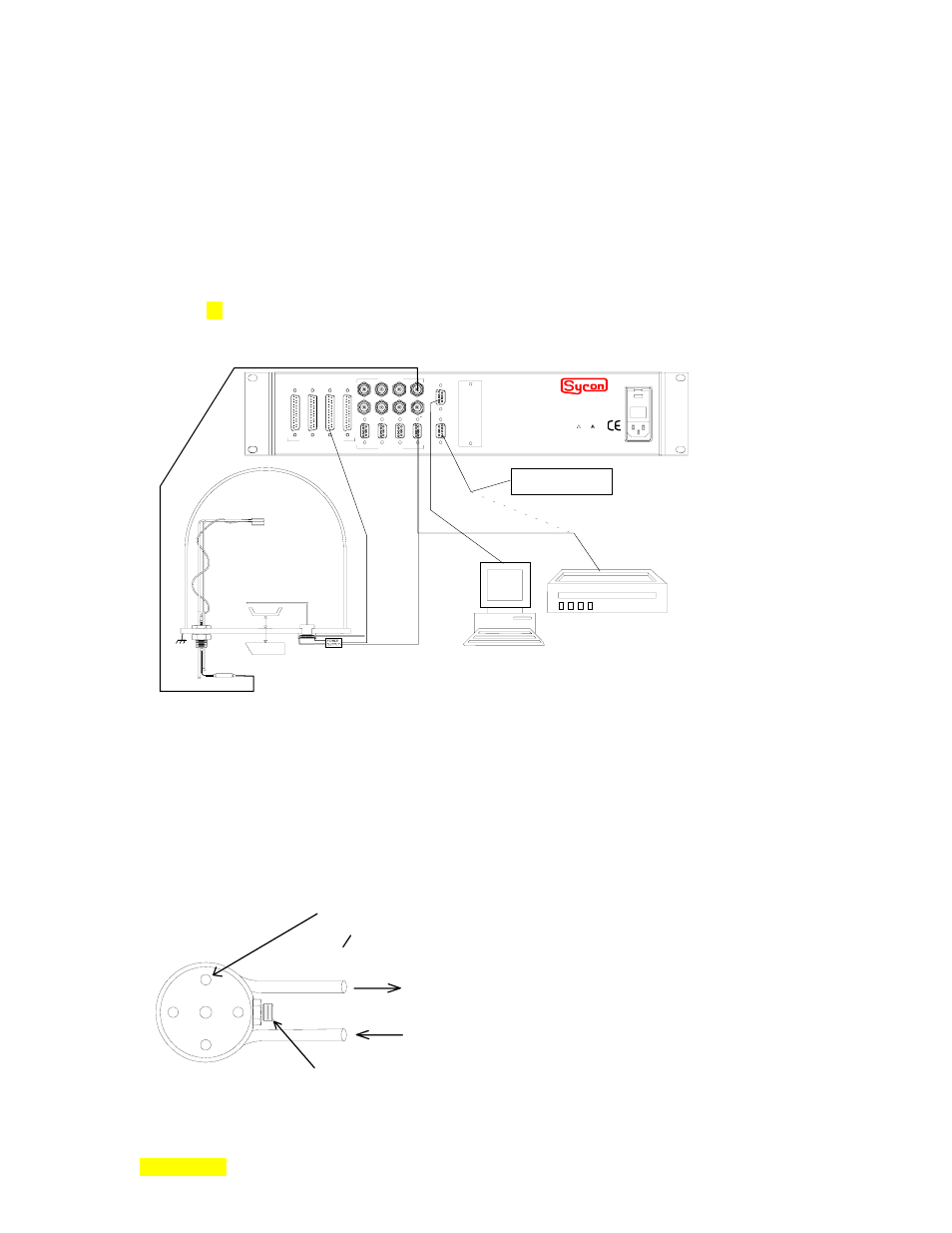

Following is a diagram of a typical evaporator installation. This diagram is repeated and described further

in Section x3 (see fig. 3.7).

CRYSTAL SENSOR

SHUTTER

DATA AQUISITION

COMPUTER

CHAMBER

DEPOSITION

SOURCE

OSCILLATOR

WARNING

!

The power cord protective

grounding conductor must be

connected to ground. No user

serviceable parts inside. Refer

servicing to qualified personnel.

FUSE: 2 x 2.00 AMP

QUICK-ACTING (F) 250v

90-264 vac, 50-60 Hz, 230VA MAX

INPUTS / OUTPUTS

SOURCE

SENSORS

I/O 4 1/O 3 I/O 2 I/O 1

COMM OPTION

RS232

MEM

instruments

Memory Module

7 5 3 1

8 6 4 2

CHART RECORDER

8 6 4 2

7 5 3 1

Sensor Installation

As a general rule the sensor head should not be installed closer than 10 inches to the evaporation

source. This minimum distance will generally provide adequate measurement sensitivity while reducing

the possibility of the source spattering small particles onto the sensor. Even small particles hitting the

crystal surface may cause the crystal to become unstable or stop oscillating completely.

The sensor should be shielded from the evaporant source by a shutter or other means when

evaporant material is being initially conditioned or outgassed.

Water Coolin

Microdot Coaxial Connec

#4-40 Tap -- 4 holes

Equally Spaced

on o0.731 B.C.

Figure- : 4.1 Head Mounting Dimensions.