Figure 3-9, Control input connector, Table 3-4 – Teledyne 9110EH - Nitrogen Oxides Analyzer User Manual

Page 33: Control input signals

Model 9110EH Instruction Manual Getting Started

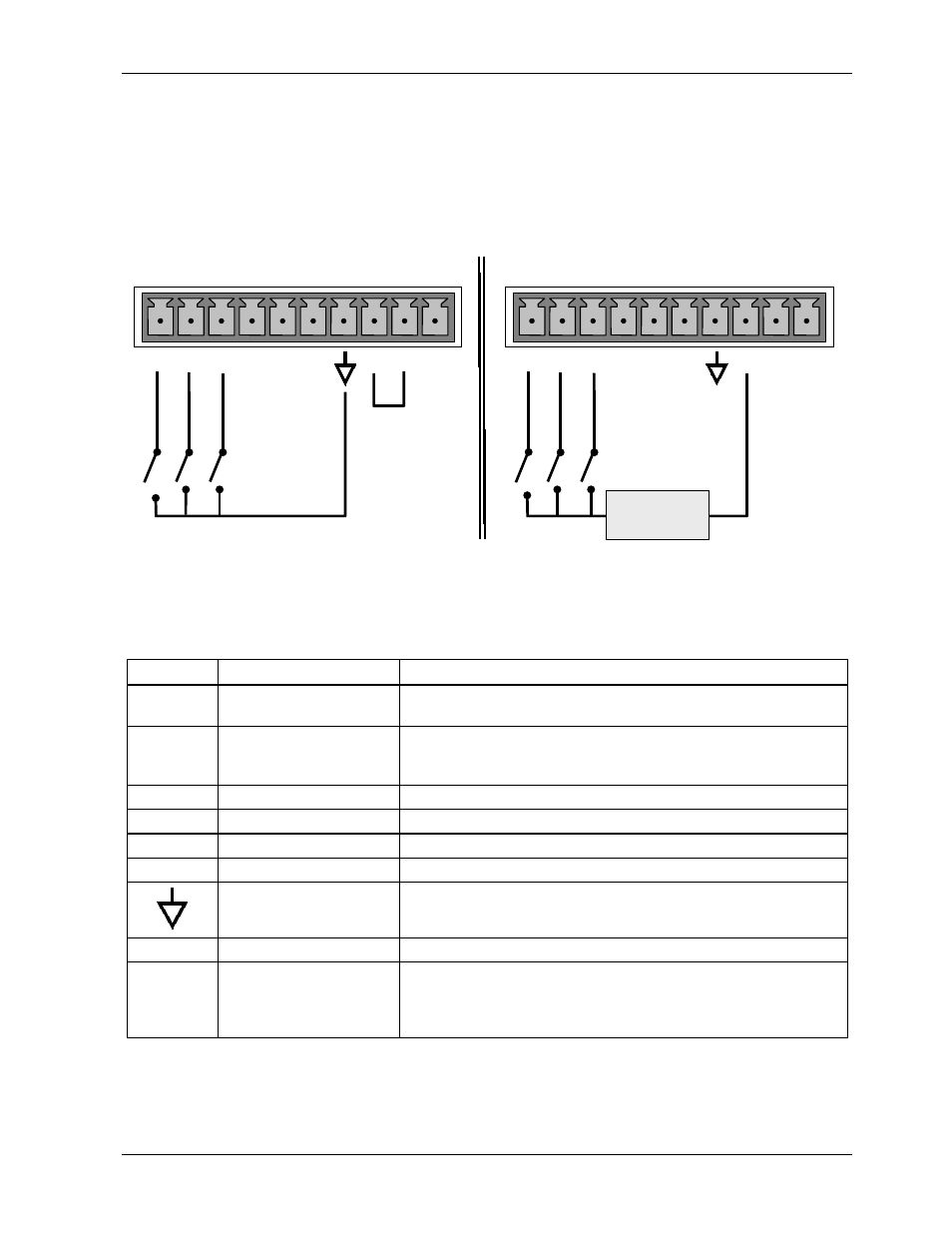

If you wish to use the analyzer to remotely activate the zero and span calibration modes,

several digital control inputs are provided through a 10-pin connector labeled CONTROL IN

on the analyzer’s rear panel.

There are two methods for energizing the control inputs. The internal +5V available from

the pin labeled “+” is the most convenient method. However, if full isolation is required, an

external 5 VDC power supply should be used.

SPAN C

A

L

ZERO CA

L

CONTROL IN

Local Power Connections

External Power Connections

SPAN C

A

L

ZERO CA

L

CONTROL IN

-

+

5 VDC Power

Supply

A B C D E F U

+

A B C D E F U

+

Figure 3-9: Control Input Connector

Table 3-4: Control Input Signals

Input #

Status Definition

ON Condition

A

REMOTE ZERO CAL

The analyzer is placed in Zero Calibration mode. The mode

field of the display will read ZERO CAL R.

B

REMOTE SPAN CAL

The analyzer is placed in low span calibration mode as part

of performing a low span (midpoint) calibration. The mode

field of the display will read LO CAL R.

C SPARE

D SPARE

E SPARE

F SPARE

Digital Ground

The ground level from the analyzer’s internal DC power

supplies (same as chassis ground).

U

External Power input

Input pin for +5 VDC required to activate pins A - F.

+

5 VDC output

Internally generated 5V DC power. To activate inputs A - F,

place a jumper between this pin and the “U” pin. The

maximum amperage through this port is 300 mA (combined

with the analog output supply, if used).

If you wish to utilize one of the analyzer’s two serial ports, attach the serial cable that is

included with the analyzer to the COM1 serial port on the rear panel. Connect the other end

to a serial port on your computer and set the computer serial port to 115000 baud transfer

M9110EH

Rev 0 19