Using the diagnostic signal i/o function, Table 11-1 – Teledyne 9110EH - Nitrogen Oxides Analyzer User Manual

Page 209

Model 9110EH Instruction Manual Troubleshooting & Repair

measurements recorded on the factory data sheet may also indicate a failure or a

maintenance item. A problem report worksheet has been provided in Appendix C

to assist in recording the value of these test functions. The following

table contains some of the more common causes for these values to be out of range.

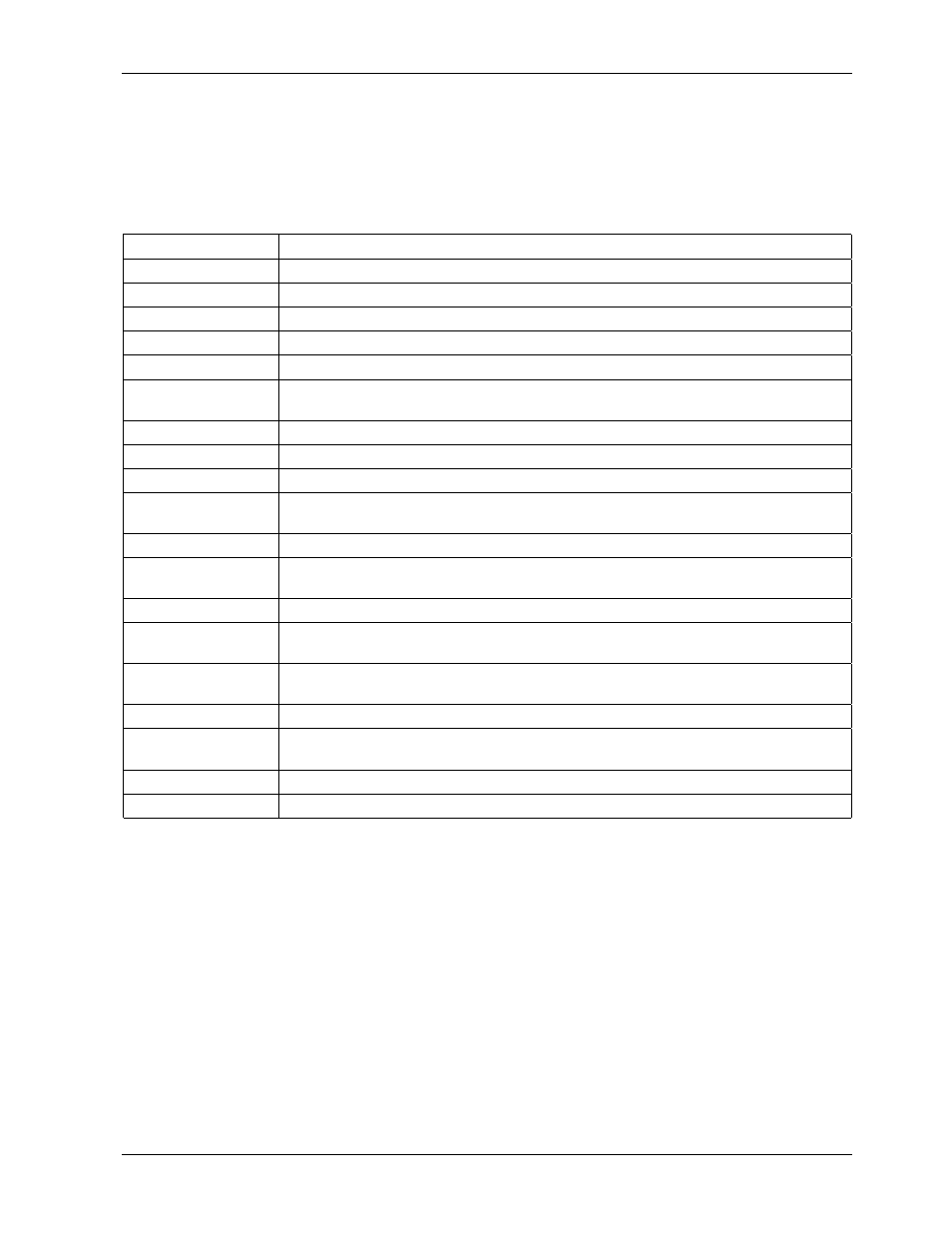

Table 11-1: Test Functions - Possible Causes for Out-Of-Range Values

Test Function

Indicated Failure(s)

NOx STB

Unstable concentrations; leaks

SAMPLE Fl

Leaks; clogged critical flow orifice

OZONE FL

Leaks; clogged critical flow orifice

PMT

Calibration off; HVPS problem; no flow (leaks)

NORM PMT

AutoZero too high

AZERO

Leaks; malfunctioning NONOx or AutoZero valve; O

3

air filter cartridge

exhausted

HVPS

HVPS broken; calibration off; preamp board circuit problems

RCELL TEMP

Malfunctioning heater; relay board communication (I

2

C bus); relay burnt out

BOX TEMP

Environment out of temperature operating range; broken thermistor

PMT TEMP

TEC cooling circuit broken; relay board communication (I

2

C bus); 12 V power

supply

IZS TEMP (option)

Malfunctioning heater; relay board communication (I

2

C bus); relay burnt out

MOLY TEMP

Malfunctioning heater; disconnected or broken thermocouple; relay board

communication (I

2

Z bus); relay burnt out; incorrect AC voltage configuration

RCEL (pressure)

Leak; malfunctioning valve; malfunctioning pump; clogged flow orifices

SAMP (pressure)

Leak; malfunctioning valve; malfunctioning pump; clogged flow orifices;

sample inlet overpressure;

NOX SLOPE

HVPS out of range; low-level (hardware) calibration needs adjustment; span

gas concentration incorrect; leaks

NOX OFF

Incorrect span gas concentration; low-level calibration off

NO SLOPE

HVPS out of range; low-level calibration off; span gas concentration incorrect;

leaks

NO OFFS

Incorrect span gas concentration; low-level calibration off

Time of Day

Internal clock drifting; move across time zones; daylight savings time?

11.1.3. Using the Diagnostic Signal I/O Function

The signal I/O parameters found under the diagnostics (DIAG) menu combined with a

thorough understanding of the instrument’s theory of operation (Chapter 10) are useful for

troubleshooting in three ways:

• The technician can view the raw, unprocessed signal level of the analyzer’s critical

inputs and outputs.

• All of the components and functions that are normally under instrument control can

be manually changed.

• Analog and digital output signals can be manually controlled.

This allows to systematically observe the effect of these functions on the operation of the

analyzer. Figure 11-2 shows an example of how to use the signal I/O menu to view the raw

M9110EH Rev 0

195