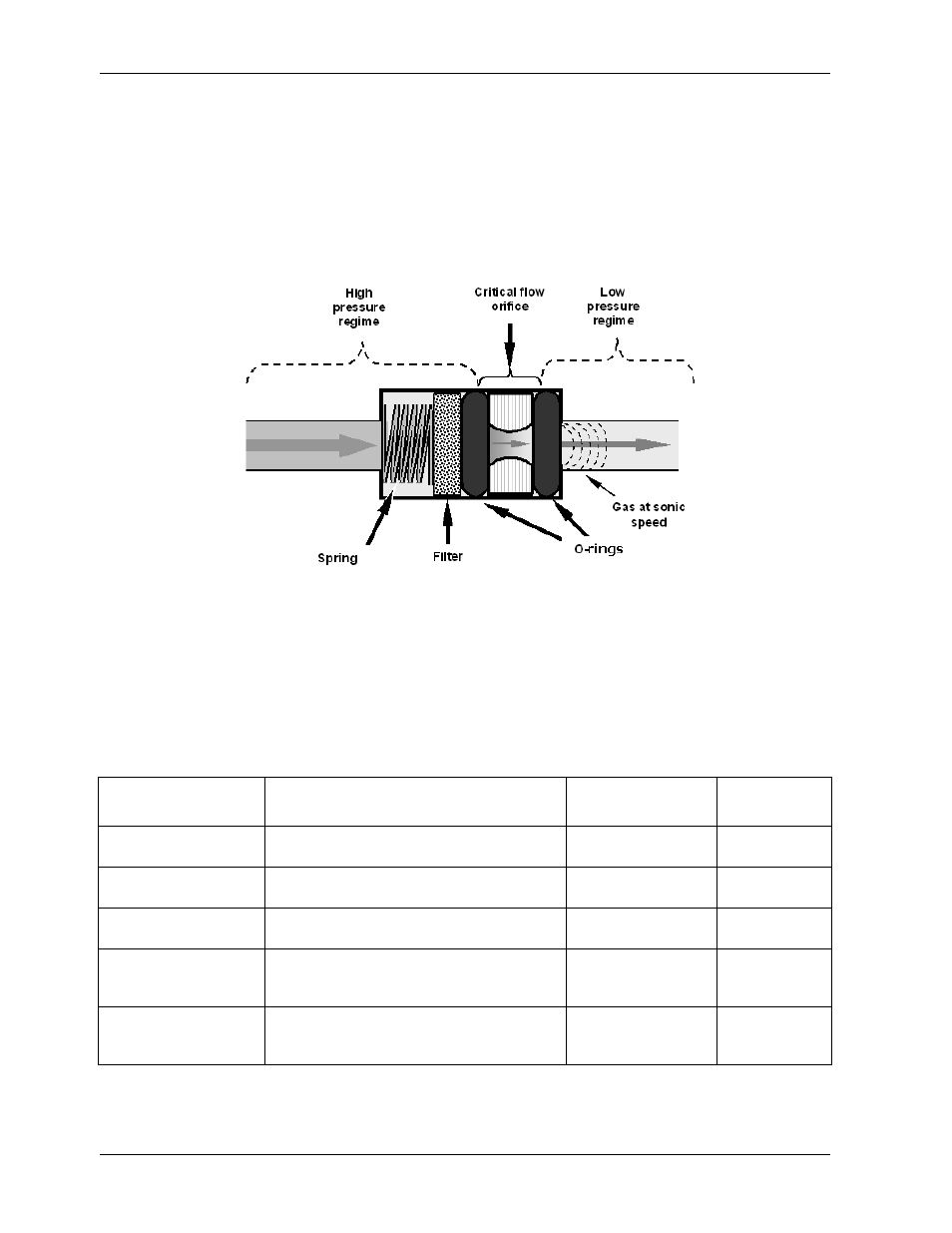

Figure 10-9, Flow control assembly & critical flow orifice, Table 10-3 – Teledyne 9110EH - Nitrogen Oxides Analyzer User Manual

Page 186: M9110eh gas flow rates

Theory of Operation Model 9110EH Instruction Manual

As the pressure on the downstream side of the orifice (the pump side) continues to drop,

the speed of the gas flowing through the orifice continues to rise. Once the ratio of

upstream pressure to downstream pressure is greater than 2:1, the velocity of the gas

through the orifice reaches the speed of sound and remains constant, regardless of any

further pressure difference. As long as that ratio stays at least 2:1, the gas flow rate is

unaffected by fluctuations, surges, or changes in downstream pressure because such

variations only travel at the speed of sound themselves and are therefore cancelled out at

the downstream exit of the critical flow orifice.

Figure 10-9: Flow Control Assembly & Critical Flow Orifice

The actual flow rate of gas through the orifice depends entirely on the size and shape of the

aperture in the orifice and the upstream pressure. The larger the hole or the higher the

upstream pressure, the more gas molecules pass through the orifice. The flow rate of the

gas is also unaffected by small degradations in pump efficiency due to age as long as the

2:1 pressure difference is maintained.

Table 10-3: M9110EH Gas Flow Rates

Location Purpose

Orifice

Diameter

Flowrate

(nominal)

Sample gas inlet of

reaction cell

Controls rate of flow of sample gas into

the reaction cell.

0.010” (0.25 mm) 500 cm³/min

O

3

supply inlet of

reaction cell.

Controls rate of flow of ozone gas into

the reaction cell.

0.004” (0.10 mm)

80 cm³/min

Dry air return of

Perma Pure

®

dryer

Controls flow rate of dry air return /

purge air of the dryer.

0.004” (0.10 mm)

80 cm³/min

Vacuum manifold ,

auto-zero port.

Controls rate of sample gas flow when

bypassing the reaction cell during the

auto-zero cycle.

0.010” (0.25 mm) 500 cm³/min

Vacuum manifold,

IZS exhaust port

Controls rate of flow of zero purge gas

through the IZS option (when installed

and enabled) when inactive.

0.004” (0.10 mm)

80 cm³/min

Note that the diameter of the critical orifice may change with temperature because of

expansion of the orifice material (ruby) and, hence, the most critical flow orifices in the

M9110EH are maintained at a constant temperature inside the reaction cell. These are the

172 M9110EH Rev 0