Pmt cooling system, Tec control board, Figure 10-14 – Teledyne 9110EH - Nitrogen Oxides Analyzer User Manual

Page 193: Schematic of basic pmt design and functionality, Y (figure 10-14), Figure 10-14)

Model 9110EH Instruction Manual Theory of Operation

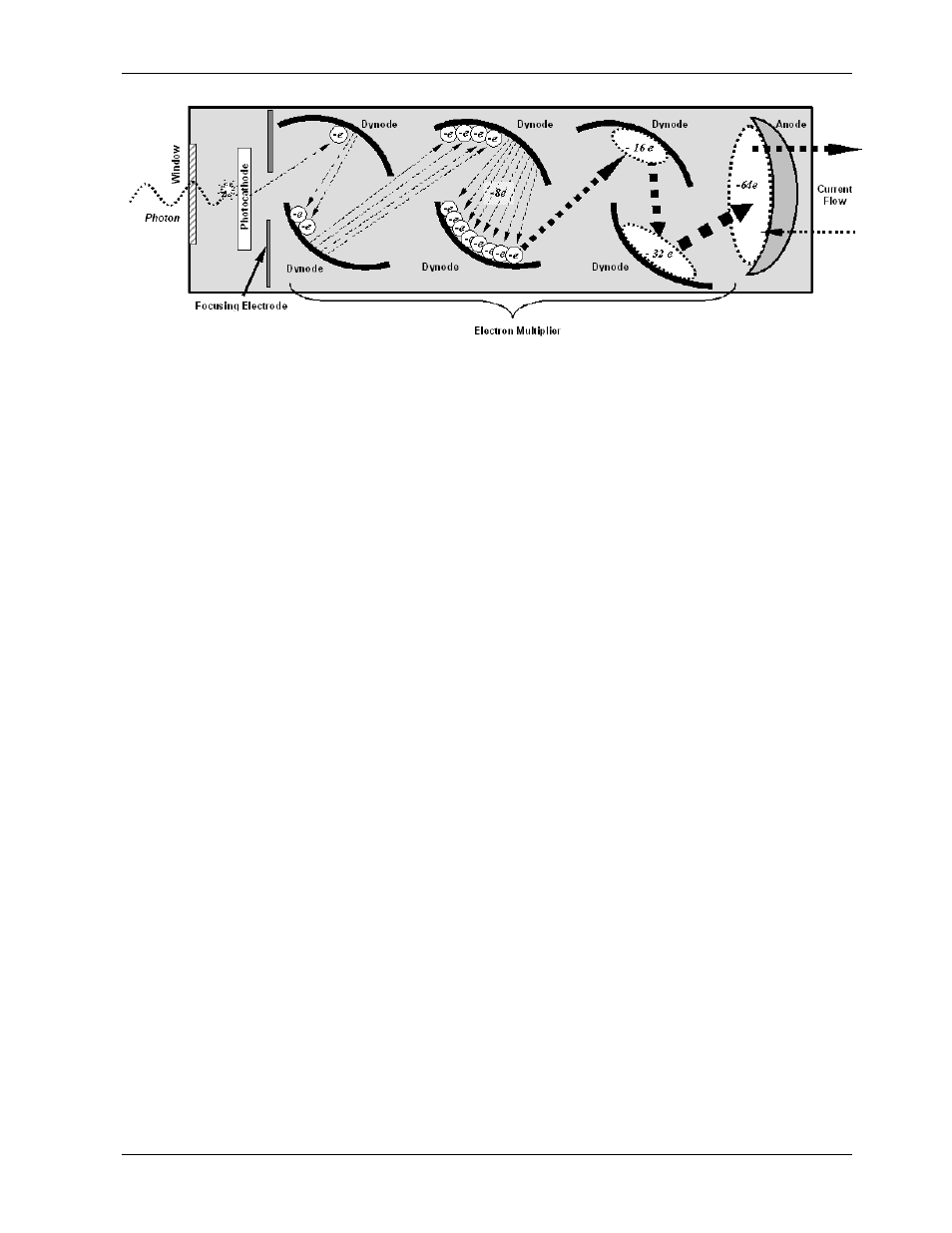

Figure 10-14:

Schematic of Basic PMT Design and Functionality

A significant performance characteristic of the PMT is the voltage potential across the

electron multiplier. The higher the voltage, the greater is the number of electrons emitted

from each dynode of the electron multiplier, making the PMT more sensitive and responsive

to small variations in light intensity but also increases random noise (dark noise). The gain

voltage of the PMT used in the M9110EH is usually set between 450 V and 800 V. This

parameter is viewable through the front panel as test function HVPS (Section 6.2.1) and

does not need to be changed unless the PMT or the HVPS itself is changed. For information

on when and how to set this voltage, see Section 11.6.5.

The PMT is housed inside the sensor module assembly (Figure 11-7). This assembly also

includes the high voltage power supply required to drive the PMT, an LED used by the

instrument’s optical test function (Section 6.7.5), a thermistor that measures the tempera-

ture of the PMT and various components of the PMT cooling system including the thermo-

electric cooler (TEC).

10.3.2.3. PMT Cooling System

The performance of the analyzer’s PMT is significantly affected by temperature. The warmer

it is, the noisier its signal becomes and significant variations in PMT temperature will render

the concentration signal useless, as it will directly reflect those variations.

The core part of the M9110EH PMT cooling system is a thermoelectric cooler (TEC), which

keeps the PMT temperature at a constant, low level (7±2°C) for optimum performance.

Thermoelectric coolers are solid state (semi-conductor) heat pumps, which transfer heat

from one side to the other when a DC current is passed through its circuits. Heat absorbed

at the cold junction (the PMT cold-block) is pumped to the hot junction (the cooling fins) at

a rate proportional to the current passing through the TEC circuit and the number of

junctions. The TEC is just one of many components in the M200E’s PMT cooling system as

shown in Figure 11-7.

10.3.2.4. TEC Control Board

The TEC control printed circuit assembly is located under the slanted shroud, next to the

cooling fins and directly above the cooling fan. Using the amplified PMT temperature signal

from the PMT preamplifier board, it sets the drive for the thermoelectric cooler. The warmer

the PMT gets, the more current is passed through the TEC.

M9110EH Rev 0

179