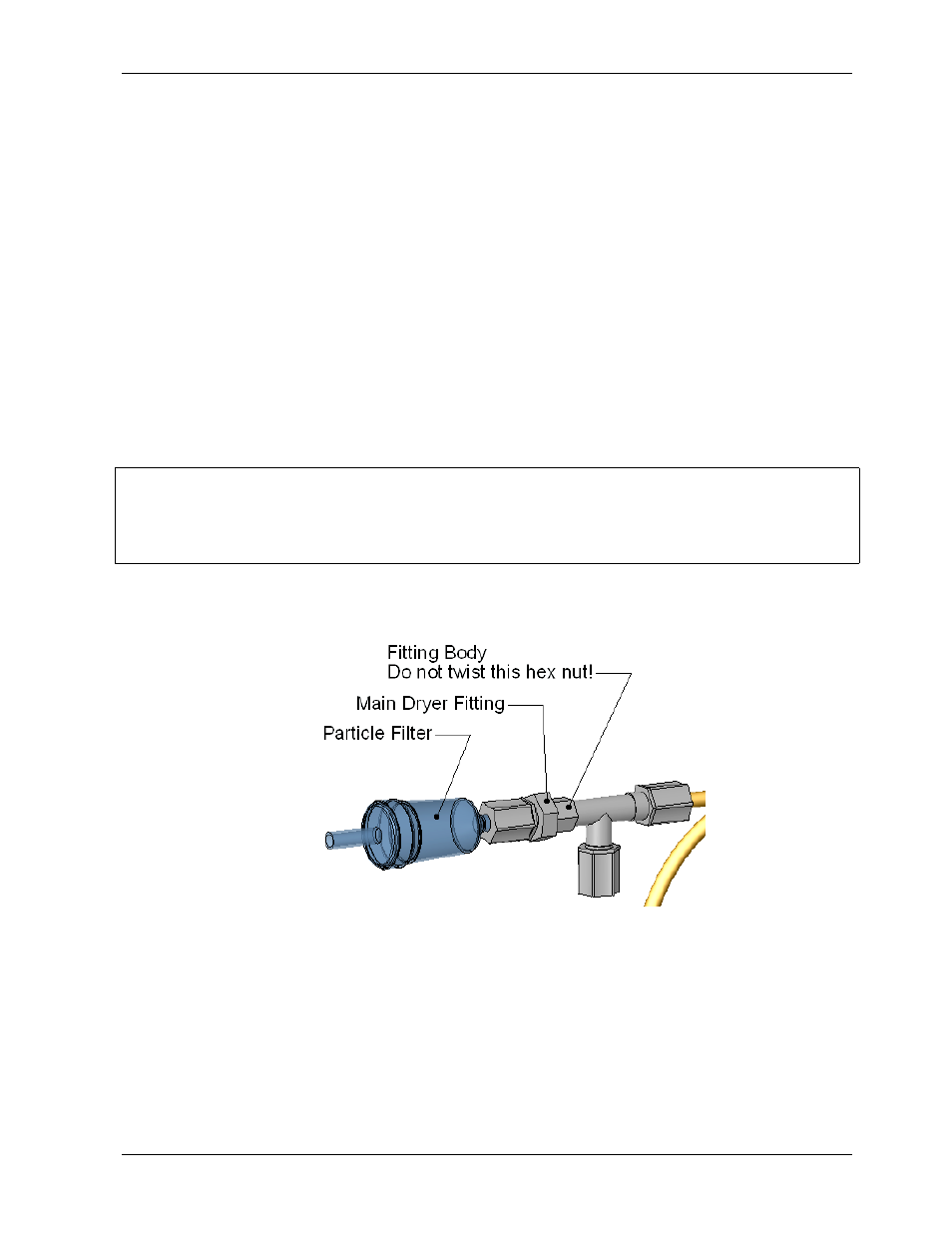

Changing the o3 dryer particulate filter, Changing the o, Dryer particulate filter – Teledyne 9110EH - Nitrogen Oxides Analyzer User Manual

Page 163: Figure 9-2, Particle filter on o, Supply air dryer

Model 9110EH Instruction Manual Instrument Maintenance

• To fulfill CE Mark safety requirements, the front panel locking screw must be

installed at all times during operation of the analyzer.

• Re-start the analyzer.

9.3.2. Changing the O

3

Dryer Particulate Filter

The air for the O

3

generator passes through a Perma Pure

©

dryer, which is equipped with a

small particulate filter at its inlet. This filter prevents dust from entering the Perma Pure

©

dryer and degrading the dryer’s performance over time. To change the filter according to

the service interval in Table 9-1:

• Before starting the procedure, check and write down the average RCEL pressure and

the OZONE flow values.

• Turn off the analyzer, unplug the power cord and remove the cover.

• Unscrew the nut around the port of the filter using 5/8” and 9/16” wrenches and by

holding the actual fitting body steady with a 7/16” wrench.

CAUTION

Risk of significant leak. Make sure to use proper wrenches and to not turn the

fitting against the Perma Pure

©

dryer. This may loosen the inner tubing and cause

large leaks.

• Take off the old filter element and replace it with a suitable equivalent

(TAPI part# FL-3).

Figure 9-2: Particle Filter on O

3

Supply Air Dryer

• Holding the fitting steady with a 5/8” wrench, tighten the nut with your hands. If

necessary use a second wrench but do not over-tighten the nut.

• Replace the cover, plug in the power cord and restart the analyzer.

• Check the O

3

flow rate, it should be around 80 cm³/min ± 15. Check the RCEL

pressure, it should be the same value as before.

M9110EH Rev 0

149