Cutout – Rockwell Automation 2711E-xxxx User Manual PanelView 1000e, 1200e 1400e User Manual

Page 39

2–8

Installing PanelView 1000e Terminals

Publication 2711E-6.17 – November 1998

4. Tighten the mounting clip screws to a torque of 10 inch-pounds. Do

not over-tighten.

!

ATTENTION: Tighten mounting clips to a torque of

10 inch-pounds to provide a proper seal and to prevent

potential damage to the terminal. Allen-Bradley

assumes no responsibility for water or chemical

damage to the terminal or other equipment within the

enclosure because of improper installation.

5. Remove the protective installation label covering the top vents of

the terminal.

!

ATTENTION: Remove the protective installation

label covering the top vents to prevent overheating and

damage to the terminal.

Mounting a Clip-Mount Keypad Terminal in a Panel or Wall

Cutout

To prepare the location:

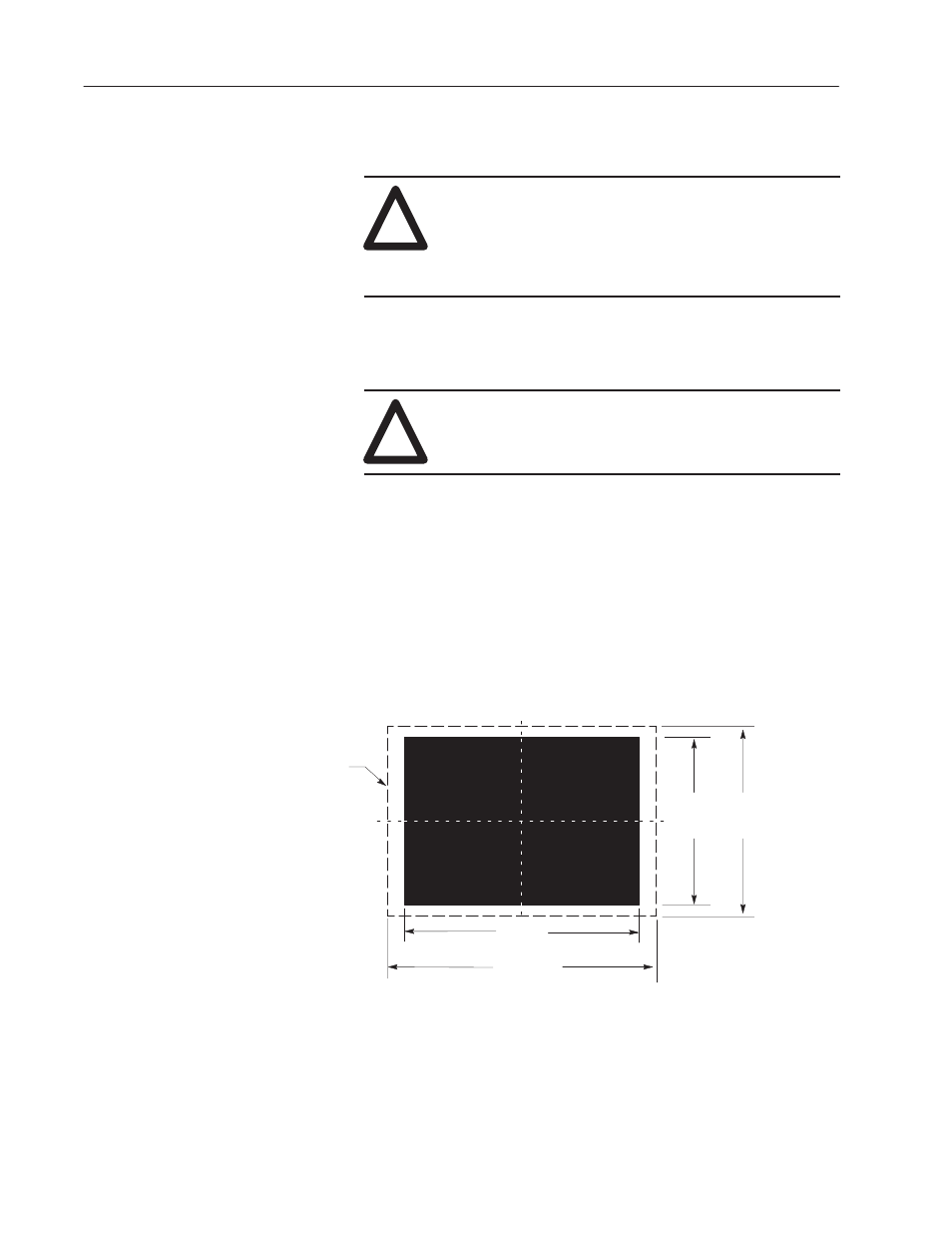

1. Make the appropriate cutout in the wall or panel location. Figure 2.7

shows the cutout dimensions for the clip-mount terminal.

2. Insert the terminal into the panel or wall cutout.

Figure 2.7 Clip-Mount Keypad Terminal Panel Cutout

24755

16.64

”

(423 mm)

15.35

”

(390 mm)

11.11

”

(282 mm)

Bezel Border Line

CUTOUT

CL

CL

10.11

”

(257 mm)

Eight assembled mounting clips are provided with the clip-mount

keypad terminals; only six clips are used for the mount.

3. Make sure the gasket is installed. If not, the terminal’s NEMA 4X

seal will not be met.