Calibration procedure for inputs – Rockwell Automation 1771-QDC PLASTIC MOLD.MODULE User Manual

Page 291

6–7

Calibration Instructions

Publication 1771-6.5.88 – July 1997

Important: Calibrate inputs before outputs. Follow this procedure for:

•

calibrating the QDC module’s inputs

•

verifying the calibration

For each calibration below, you will:

•

apply precise voltages using the input wiring arm

•

enter command codes in BTW word 2 with your programming

terminal

For each verification below, you will:

•

apply precise voltages using the input wiring arm

•

read verification codes in BTR words 10-13

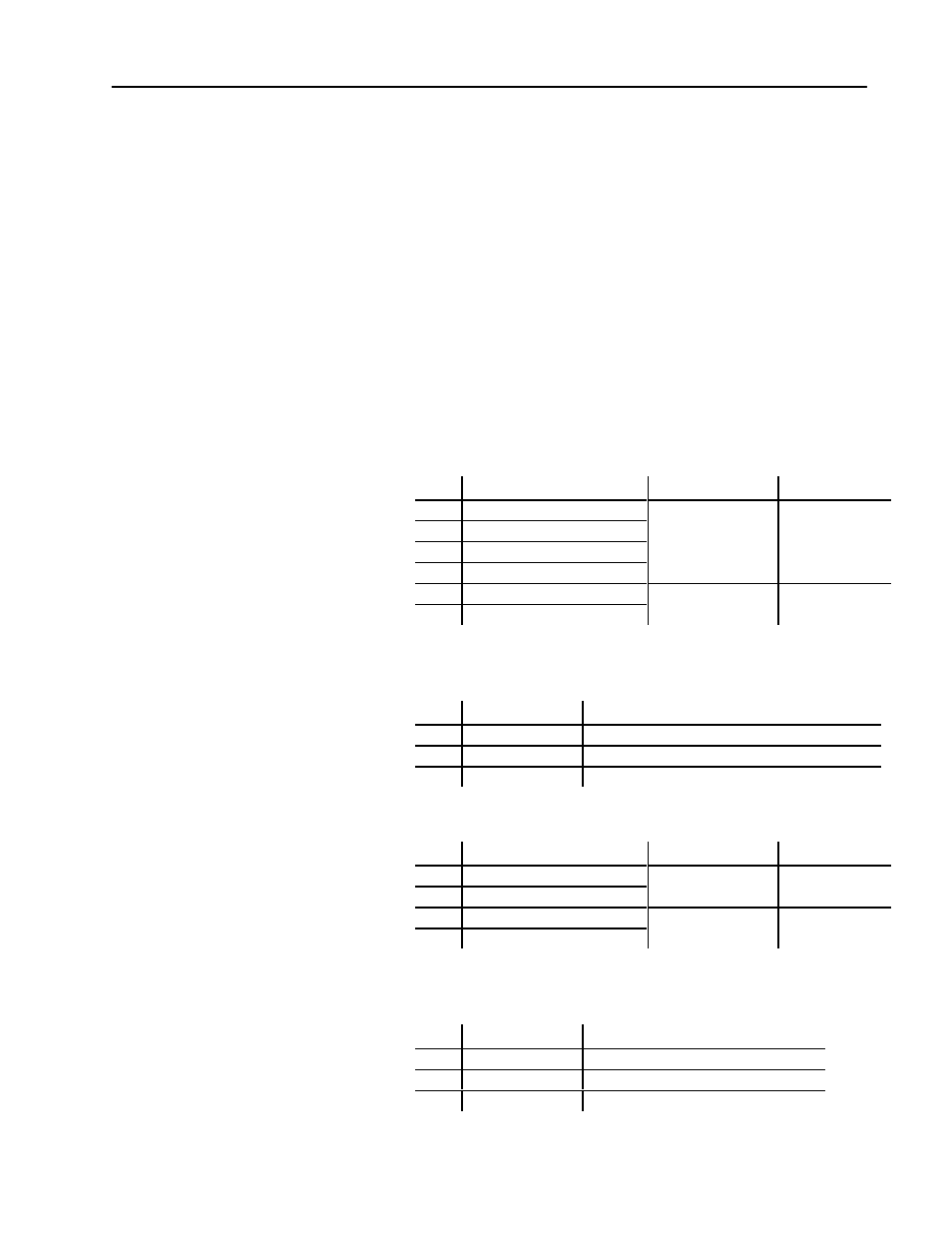

1. To calibrate the 0 to +10V dc range:

Step

Enter Command Code (BTW 2):

With Applied Voltage

and Read in BTR:

1

0000H

000.0

word 2 = 000F

2

8000H

3

0008H

4

8008H

5

0008H

10.000

word 3 = 000F

6

8008H

2. To verify 0 to +10V range, enter command codes 0100H and 8100H.

Then apply the following voltages:

Step

Apply this Voltage

and Read Verification Code (BTR 10-13):

1

000.0

000H

2

5.000

800H

3

9.997

FFFH

3. To calibrate the 1 to 5V dc range:

Step

Enter Command Code (BTW 2):

With Applied Voltage

and Read in BTR

1

0010H

1.000

word 2 = 00FF

2

8010H

3

0010H

5.000

word 3 = 00FF

4

8010H

4. To verify 1 to 5V range, enter command codes 0400H and 8400H.

Then apply the following voltages:

Step

Apply this Voltage

and Read Verification Code (BTR 10-13):

1

1.000

000H

2

3.000

800H

3

5.000

FFFH

Calibration Procedure

for Inputs