Rlc - inject erc values block, Rlc – inject erc values block – Rockwell Automation 1771-QDC PLASTIC MOLD.MODULE User Manual

Page 162

2–96

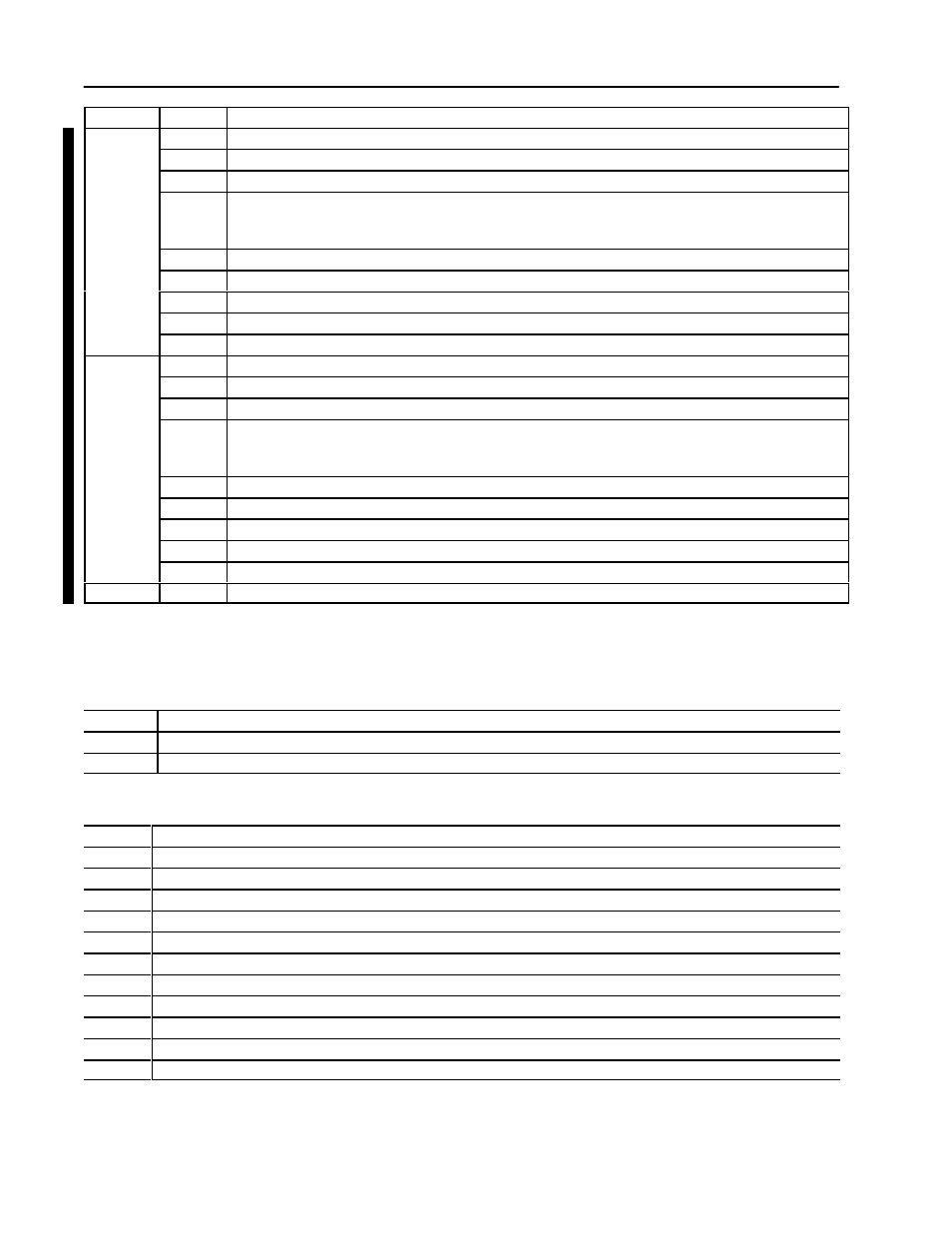

Command Word/Bit Descriptions

Publication 1771-6.5.88 – July 1997

Notes: 1. For [ ] engineering units, see page 3.

2. When using the Inject/Clamp/Eject mode, all pressure readings are system pressure at input 2, except where noted.

Word

Description

Bit

PTC10

Trace #3 selection

B01

Injection position

B02

Injection pressure

B03

Injection velocity

The module will return unscaled injection position data if injection velocity is selected. The process trace screen uses

this position information to calculate and display velocity.

B04

Cavity pressure

B05

Screw RPM

B06

Injection flow valve output

B07

Injection pressure valve output

B08 - B15

Reserved Do not use.

PTC11

Trace #4 selection

B01

Injection position

B02

Injection pressure

B03

Injection velocity

The module will return unscaled injection position data if injection velocity is selected. The process trace screen uses

this position information to calculate and display velocity.

B04

Cavity pressure

B05

Screw RPM

B06

Injection flow valve output

B07

Injection pressure valve output

B08 - B15

Reserved Do not use.

PTC12 - 64

Open

Bit-mapped Control Words

Word

Description

RLC01

Block ID = 00011010 (Low byte). High byte reserved for the module. Do not use.

RLC02 - 08

Open

Injection Profile ERC Values

Word

Description

RLC09

Injection Segment 1

RLC10

Injection Segment 2

RLC11

Injection Segment 3

RLC12

Injection Segment 4

RLC13

Injection Segment 5

RLC14

Injection Segment 6

RLC15

Injection Segment 7

RLC16

Injection Segment 8

RLC17

Injection Segment 9

RLC18

Injection Segment 10

RLC19

Injection Segment 11

RLC – Inject ERC Values

Block