Related documentation, Abbreviations, symbols, and terms – Rockwell Automation 1771-QDC PLASTIC MOLD.MODULE User Manual

Page 16

Preface

P–2

Publication 1771-6.5.88 – May 1997

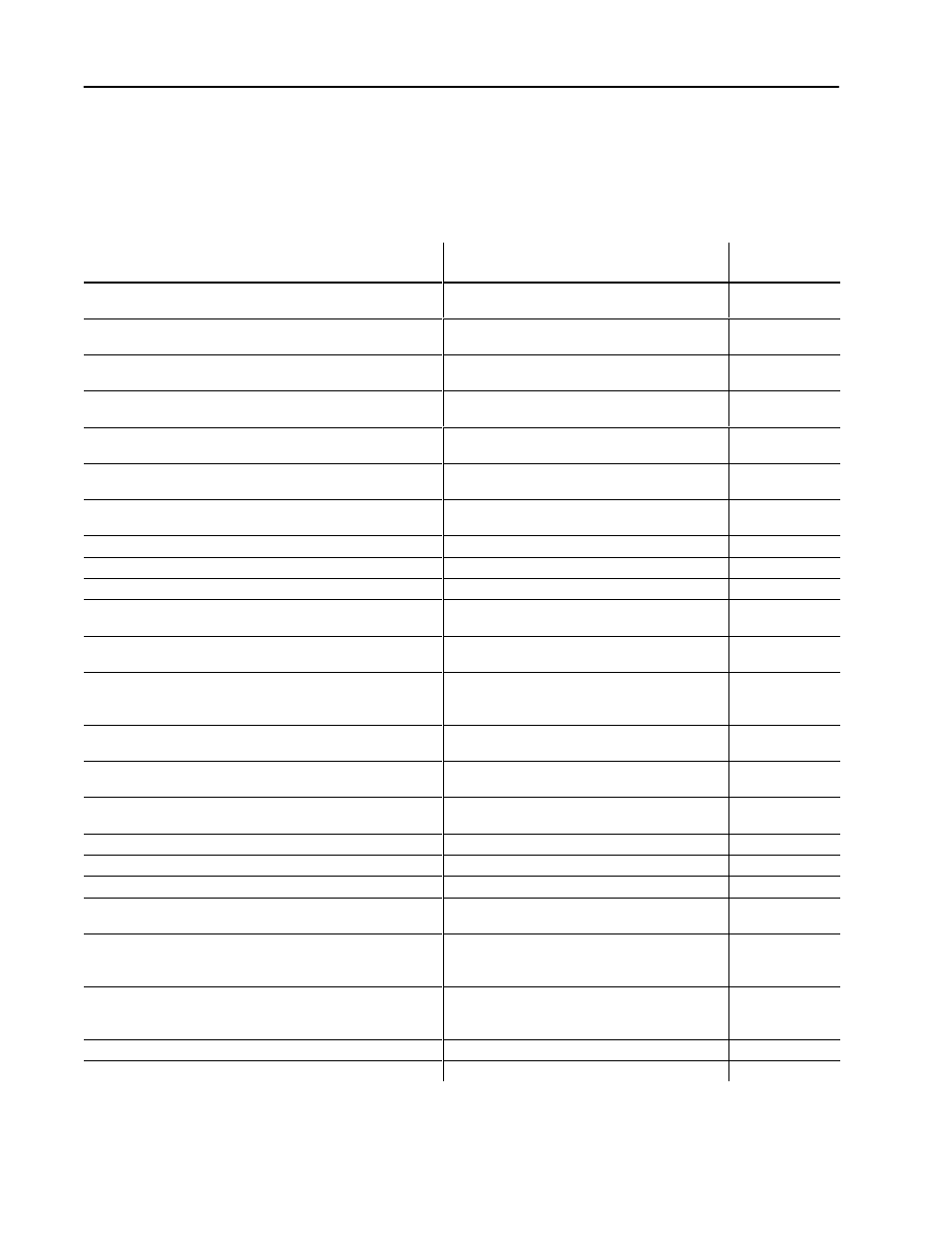

Related Documentation

The following documents contain additional information concerning

Allen-Bradley QDC and PLC products. To obtain a copy, contact

your local Allen-Bradley office or distributor.

For

Read This Document

Document

Number

In-depth information on grounding and wiring Allen-Bradley

programmable controllers

Allen-Bradley Programmable Controller Grounding

and Wiring Guidelines

1770-4.1

Selecting your QDC module’s mode of operation and matching it to

your machine’s hydraulics

Plastic Molding Module Application Guide

1771-4.10

Installing and configuring your QDC module to control inject

operations

Plastic Molding Module User Manual 1771-QDC

Inject Mode Operation

1771-6.5.85

Installing and configuring your QDC module to control both inject

and clamp operations

Plastic Molding Module User Manual, 1771-QDC

Inject and Clamp Mode Operation

1771-6.5.86

Installing and configuring your QDC module to control both clamp

and eject operations

Plastic Molding Module User Manual, 1771-QDC

Clamp and Eject Mode Operation

1771-6.5.87

Installing and configuring your QDC module to control inject, clamp,

and eject operations

Plastic Molding Module User Manual, 1771-QDC

Inject, Clamp, and Eject Mode Operation

1771-6.5.93

Selecting instructions and organizing memory when writing ladder

logic to run your machine

1785 PLC-5 Programmable Controller

Instruction Set Reference

1785-6.1

Installing the PLC processor and I/O modules

1785 PLC-5 Programmable Controller Quick Start

1785-10.4

Installing Pro-Set 700 injection molding software

Pro-Set 700 Installation Instructions

6500-5.4

Installing your Pro-Set 700 operator interface

Pro-Set 700 Operator Interface Installation Manual

6500-6.2.1

Customizing Pro-Set 700 software for your application

Pro-Set 700 Software Release 2.1 Reference

Manual

6500-6.4.3

Selecting the Pro-Set 600 software that matches the requirements

of your molding machine

Pro-Set 600 Operator Interface Software for Injection

Molding Designer’s Guide

6500-6.5.11

Transferring your Pro-Set 600 software from a floppy to your hard

drive and adding overlays into your PLC-5 and PanelView

application files

Pro-Set 600 Operator Interface Software for Injection

Molding Software Assembly Manual

6500-6.5.12

Installing Pro-Set 600 overlay(s) into your application files

Pro-Set 600 Operator Interface Software for Injection

Molding Software Overlay Installation Manual

6500-6.5.13

Customizing your Pro-Set 600 build for your machine control

requirements.

Pro-Set 600 Operator Interface Software for Injection

Molding Software Customization Manual

6500-6.5.14

Support to customize your software control system.

Pro-Set 600 Operator Interface Software for Injection

Molding Software Reference Manual

6500-6.5.15

Setting up your molding machine for use with Pro-Set 700 software

Pro-Set 700 Software Release 2.1 User Manual

6500-6.5.18

Using co-injection software

Pro-Set 700 Co-injection Software User Manual

6500-6.5.19

Inputting injection molding system setpoints and actuals

Pro-Set 700 Systems Jobsetting Guide

6500-6.9.3

Installing modules for co–injection applications

Installing Co-injection and Plastic Molding Modules

Quick Start

6500-10.1

A description of important differences between solid-state

programmable controller products and hard-wired

electromechanical devices

Application Considerations for Solid-State Controls

SGI-1.1

An article on wire sizes and types for grounding electrical

equipment

National Electrical Code

National Fire

Protection Assoc.

of Boston, MA.

A complete listing of current Allen-Bradley documentation

Allen-Bradley Publication Index

SD499

A glossary of industrial automation terms and abbreviations

Allen-Bradley Industrial Automation Glossary

AG-7.1

The following abbreviations, symbols, and terms are specific to this

Abbreviations, Symbols,

and Terms