Map your btw and btr data blocks, Write your calibration logic – Rockwell Automation 1771-QDC PLASTIC MOLD.MODULE User Manual

Page 286

6–2

Calibration Instructions

Publication 1771-6.5.88 – July 1997

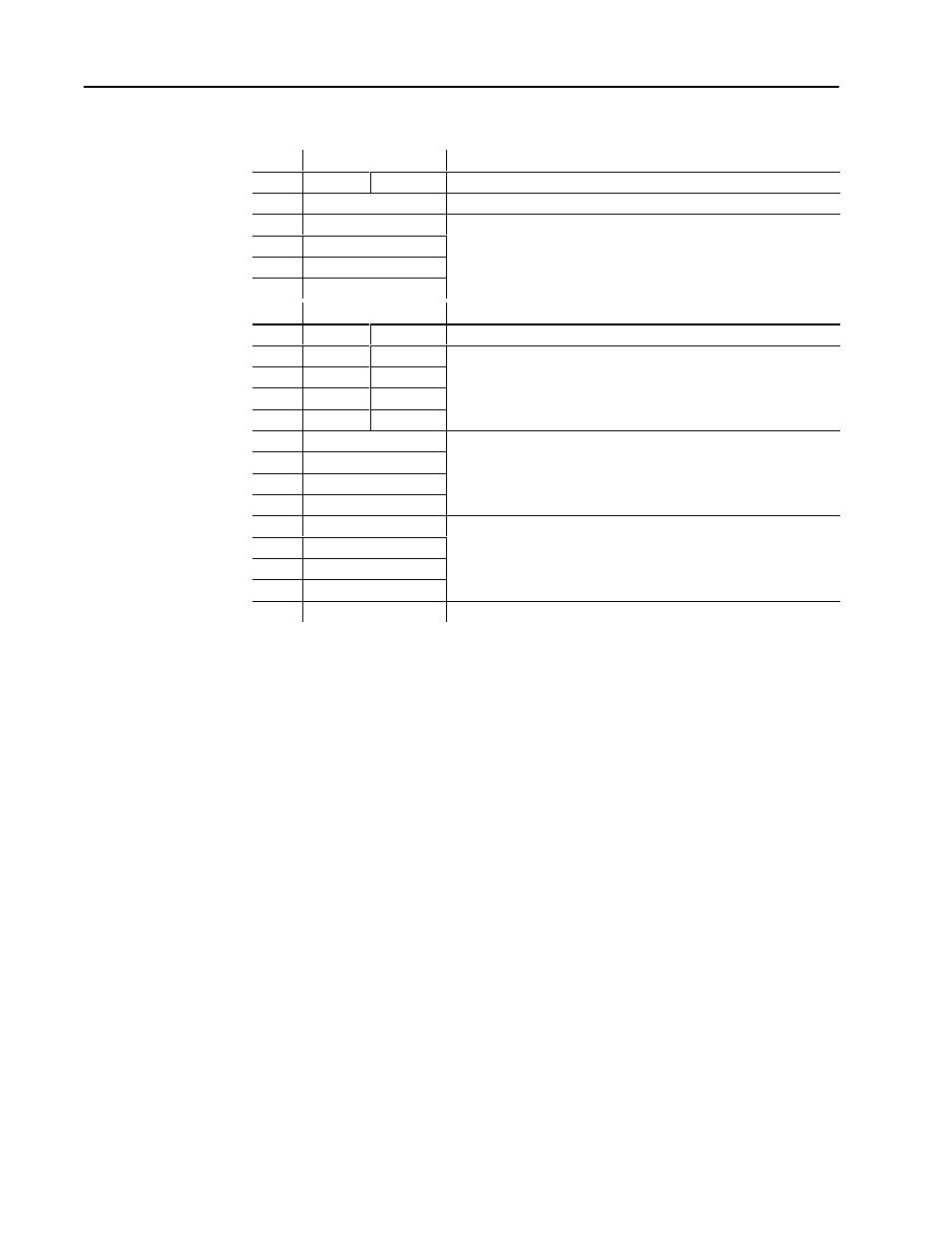

Create BTR and BTW calibration data blocks in your PLC-5 data table.

word

BTW file

description

1

–

1C

ID that you enter

2

Command Word

Command codes that you enter

3

Output 1

Codes that you enter during the calibration procedure

4

Output 2

5

Output 3

6

Output 4

word

BTR file

description

1

Status

0A

Status and ID that you observe

2

–

Min Input

Values that you observe during the calibration procedure

3

–

Max Input

4

–

Min Output

5

–

Max Output

6

Actual Input 1

Raw data from D/A converter (useful but not required during calibration)

7

Actual Input 2

8

Actual Input 3

9

Actual Input 4

10

Calibrated Input 1

Values that you observe during the calibration procedure

11

Calibrated Input 2

12

Calibrated Input 3

13

Calibrated Input 4

15

Echo of your command

Indicates the transfer of data blocks

Record BTR and BTW file addresses for use in your calibration logic.

Write your calibration logic as follows:

1. Write unconditional BTW and BTR instructions

(use a block length of 0 for processor-controlled length).

2. Unlatch BTW and BTR enable bits with BTW and BTR done bits.

3. Assign the module address and data table addresses.

Important: The module address of your BTR and BTW instructions

depends on the location of the QDC module in the I/O

chassis. If you do not have an extender card that lets

you access jumpers on the QDC module circuit board,

place the module in the right-most slot and access the

jumpers from inside the I/O chassis. Change the slot

block transfer address to match the I/O chassis slot

location of the module.

We present example calibration logic for instructional purposes only.

Map Your BTW and BTR

Data Blocks

Write Your

Calibration Logic