Par 153 – Rockwell Automation 20D PowerFlex 700S AC Drives with Phase II Control Programming Manual User Manual

Page 43

Rockwell Automation Publication 20D-PM001C-EN-P - July 2013

43

Programming and Parameters

Chapter 2

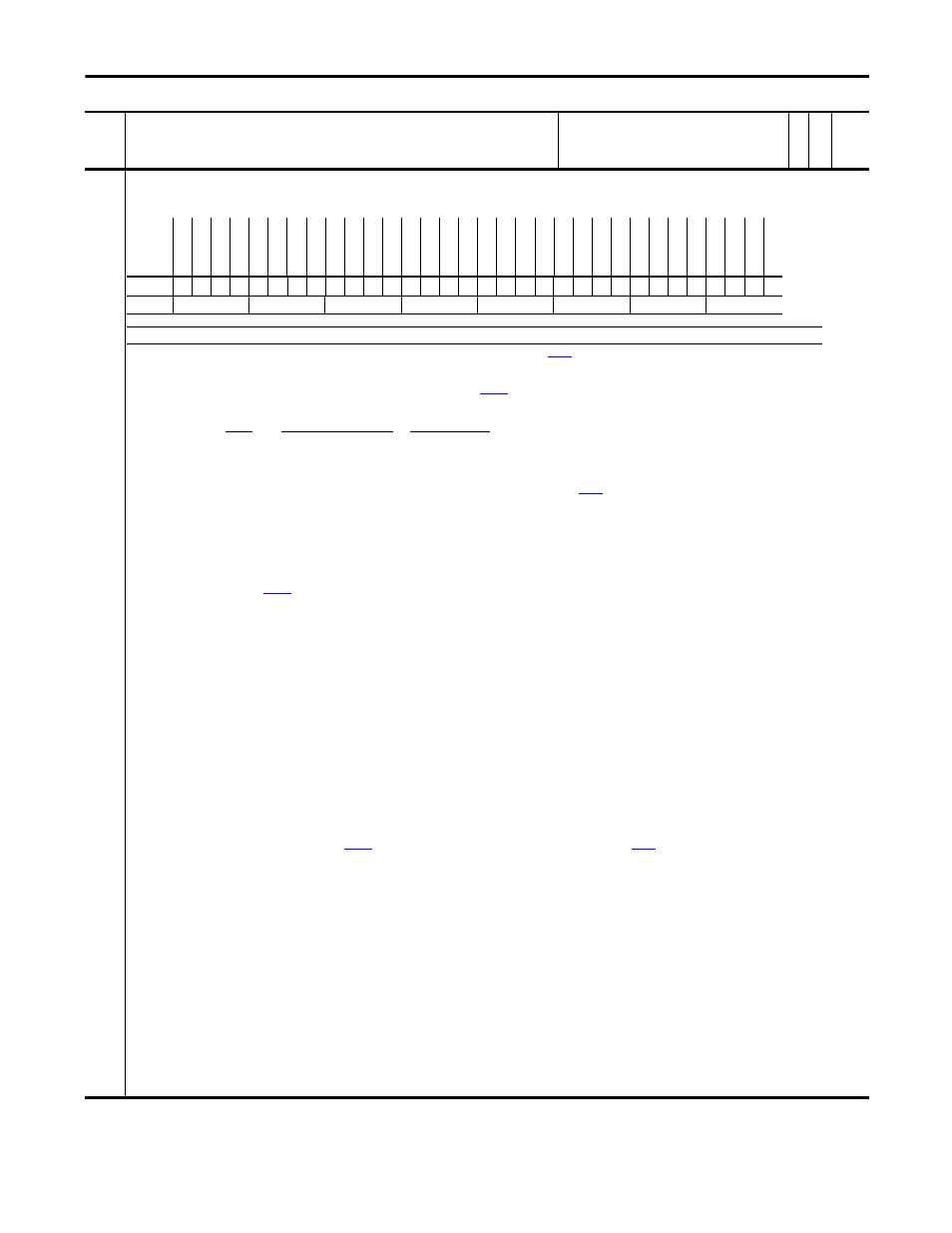

153

Control Options

Set bits to configure the options for operating the drive. Note: Bit 3 “Flying Start” was added for firmware version 2.004. Bit 20, 21, and 29 were added for firmware version 3.001. Added bit 31 “Ids

Test Enable” for firmware version 4.001.

No.

Name

Description

Values

Link

able

Re

ad

-Write

Da

ta

T

yp

e

Options

Id

s T

est E

nabl

e

Sy

s In

rt

E

n

Slip

Te

st

En

PM O

ff

set En

Pwr

Di

ag

E

n

Tr

q Tr

im

E

n

MC A

tune En

Ti

me

A

xi

s E

n

PIT

rim EnO

ut

Re

se

rv

ed

Inr

t T

rqLPEn

Mot

or OL

Ret

Slip

C

omp

E

n

SpdRegPr

eset

Au

x P

w

r S

ply

Au

to

T

ac

h Sw

Re

se

rv

ed

D

M

Re

se

rv

ed

D

M

OL Cl

sLpD

sbl

Jo

g -

N

oI

nt

eg

Iq D

el

ay

Mot

or Dir

Re

se

rv

ed

3W

ireC

on

tr

ol

Tr

q D

sbl

ZS

pd

Tr

q S

to

pR

am

p

Jo

g -

N

oR

amp

Jo

g i

n T

rq

Fl

ying Star

t

SErrF

ilt1S

tg

SRef

L

dL

g En

Bip

ol

ar S

Ref

Default

0

0

0

0

0

0

0

0

0

x

1

0

0

0

0

0

0

0

0

0

0

0

0

1

0

0

0

0

1

0

0

1

Bit

31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9

8

7

6

5

4

3

2

1

0

Bit

Name

Current Function

0

Bipolar SRef

When this bit is enabled a bipolar speed reference is used. In bipolar reference mode,

[Selected Spd Ref] indicates both the speed magnitude and the

direction: Positive speed reference values (+) = forward direction and negative speed reference values (–) = reverse direction. When this bit is disabled a

unipolar speed reference is used. In unipolar mode, the speed reference is limited to a minimum value of zero (0). In this case Par 40 [Selected Spd Ref]

supplies only the speed magnitude. The direction is determined by

[Applied LogicCmd] bits 20 “Forward” and 21 “Reverse”. The forward/reverse

direction button on the HIM is one possible source for the Applied Logic Command direction bits. The following chart explains the effect that the direction

button on the HIM has based on the condition of the “Bipolar SRef” bit:

Bipolar

Reference Controlled By HIM?

HIM Direction Button

Enabled

Yes

Changes the motor direction due to a HIM supplied (+) or (-) command signal.

Enabled

No

Has no effect on motor direction. Direction determined by sign of Par 40 [Selected Spd Ref].

Disabled

Yes

Changes the motor direction due to a HIM supplied Forward or Reverse Logic Command bit.

Disabled

No

Changes the motor direction due to a HIM supplied Forward or Reverse Logic Command bit.

In either Bipolar or Unipolar mode, the selected direction can be determined from the sign of

[Limited Spd Ref]. Positive values indicate forward

rotation and negative values indicate reverse rotation.

1

SRef LdLg En

Enables/disables the Speed Reference Lead Lag Filter

2

SErrFilt1Stg

Setting this bit will configure the speed error filter as a single first order low pass filter. Clearing this bit will configure the speed error filter as two cascaded

first order low pass filters

3

Flying Start

Enables/disables the function which reconnects to a spinning motor at actual rpm when a start command is issued

4

Jog in Torq

Overrides

[Speed/TorqueMode] setting when a jog command is received

5

Jog-NoRamp

Bypasses the Speed Reference Ramp and S-Curve

6

Trq StopRamp

Overrides Par 110 [Speed/TorqueMode] setting when stopping

7

Trq DsblZSpd

Configures how the drive uses stop dwell time

8

3WireControl

Configures the drive for 3-wire control

10

Motor Dir

Changes direction of the motor rotation

11

Iq Delay

Enables the Torque Current Delay option

12

Jog-NoInteg

Configures the speed regulator’s integrator to “hold” when jogging

13

OL ClsLpDsbl

Overload Closeloop Calculation Disable

14

Reserved DM

Reserved for use by the Drive module for “Invert Speed Feedback”

15

Reserved DM

Reserved for use by the Drive module for “Invert Motor Torque Current”

16

Auto Tach Sw

Switches the drive to secondary motor feedback. This bit cannot be set when Par 485 [Motor Ctrl Mode] = 2 “PMag Motor”.

17

Aux Pwr Sply

Enables the use of an auxiliary power supply. When set to 1, the Main Control Board (MCB) examines internal 12V DC power to see when it is energized. When

set to 0, the MCB examines the voltage of the DC Bus. This bit enables the MCB to remain energized when 3-Ø voltage is de-energized.

18

SpdRegPreset

When set to “1”, this bit selects

[Motor Torque Ref] for the Speed Regulator preset. When set to “0”,

[SReg Trq Preset] is selected.

19

Slip Comp

Enables slip compensation

20

Motor OL Ret

Enables motor over-load retention

21

Inrt TrqLPEn

Enables the Inertia Compensation Torque Output Low Pass Filter

23

PITrim EnOut

Enables the output of Process Trim

24

Time Axis En

Ramps the output of the Time Function Generator

25

MC Atune En

Enables Autotune tests

26

Trq Trim En

Enables Torque Trim

27

Pwr Diag En

Enables the Power Diagnostic test

28

PM Offset En

Enables the Permanent Magnet Motor offset test

29

Slip Test En

Enables the Slip Frequency Auto-Tune function

30

Sys Inrt En

Enables the System Inertia test

31

Ids Test Enable

Enables the flux producing (d-axis) current test for the Field Oriented Control (FOC) encoder mode

0 = False

1 = True