Internal zero/span (izs) (option 51) – Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 52

Optional Hardware and Software

Model 9110E Instruction Manual

38

M9110E Rev B

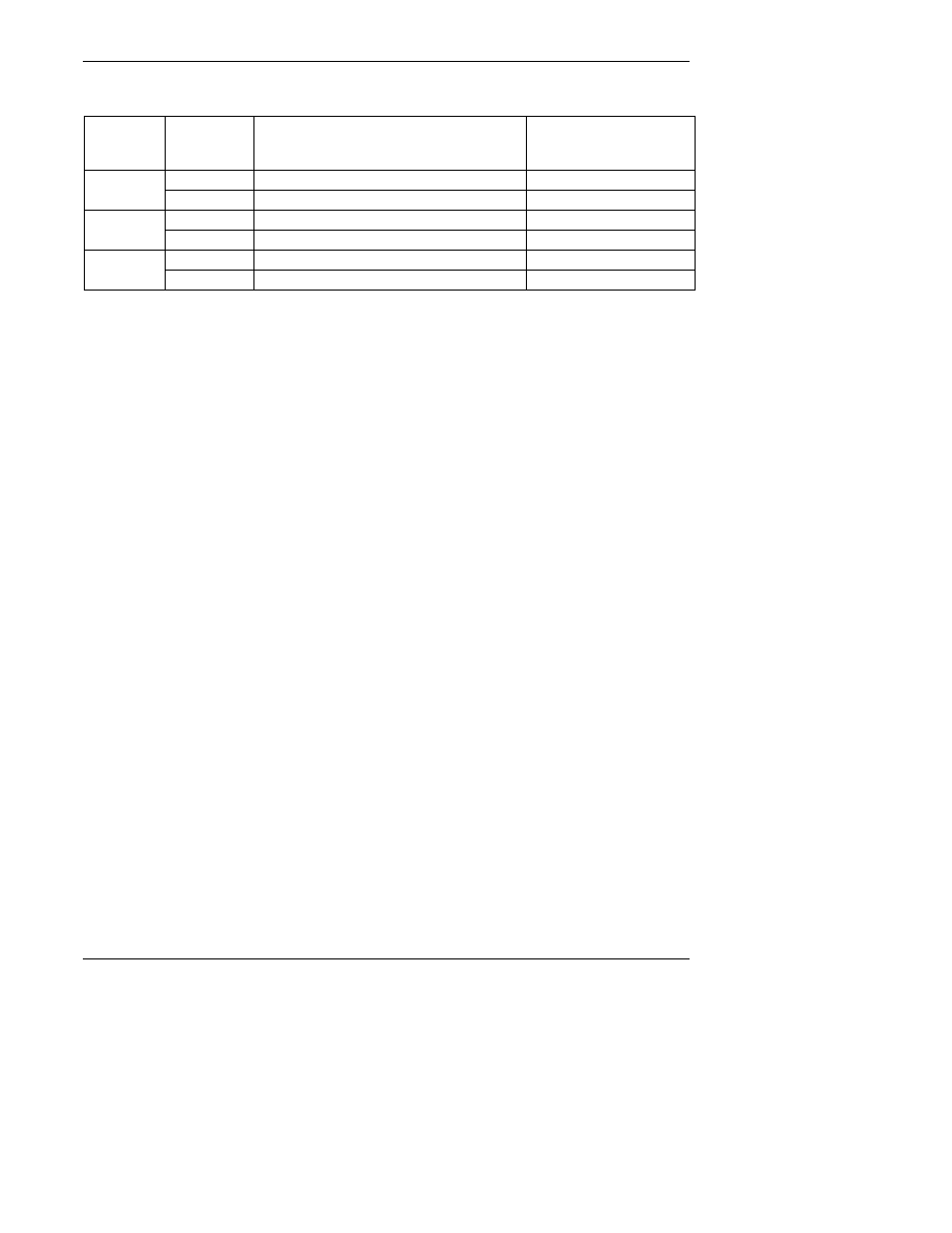

Table 5-1: IZS or Z/S Valve States

Mode Valve

Condition

Valve Port Connection

NO = normally open port

NC = normally closed port

COM = common port

Sample/Cal

Open to sample gas inlet

NO Æ COM

SAMPLE

Zero/Span

Open to zero air inlet

NO Æ COM

Sample/Cal

Open to zero/span inlet (activated)

NC Æ COM

ZERO CAL

Zero/Span

Open to zero air inlet

NO Æ COM

Sample/Cal

Open to zero/span inlet (activated)

NC Æ COM

SPAN CAL

Zero/Span

Open to span gas inlet / IZS gas (activated)

NC Æ COM

The state of the IZS valves can also be controlled:

• Manually from the analyzer’s front panel by using the SIGNAL I/O controls located

under the DIAG Menu (Section 6.8.1),

• By activating the instrument’s AutoCal feature (Section 7.8),

• Remotely by using the external digital control inputs (Section 6.9), or

• Remotely through the RS-232/485 serial I/O ports (Section 6.9.10).

Sources of zero and span gas flow must be capable of supplying at least 600 cm

3

/min as

the analyzer draws about 500±50 cm³/min into the instrument. Both supply lines should be

vented outside of the analyzer’s enclosure. In order to prevent back-diffusion and pressure

drop effects, these vent lines should be between 2 and 10 meters in length.

5.6.2. Internal Zero/Span (IZS) (Option 51)

The M9110E can be equipped with an internal zero air and span gas generator system

(IZS). This option includes a heated enclosure for a NO

2

permeation tube, an external

scrubber for producing zero air and two valves for switching between the sample gas inlet

and the output of the zero/span subsystem, functionally identical to the zero/span valve

option.

The IZS option includes a two stage, external zero air scrubber assembly that removes all

NO & NO

2

from the zero air source. The scrubber is filled with 50% Purafil Chemisorbant

®

(for conversion of NO to NO

2

) and 50% activated charcoal (for removal of NO

2

). This

assembly also includes a small particle filter.

Span gas is created by passing zero air over a NO

2

permeation tube. This tube contains

liquid NO

2

, which slowly permeates through a permeable membrane into the surrounding

air. The concentration of the NO

2

span gas is determined by three factors:

• Size of the membrane: The larger the area of the membrane, the more permeation

occurs.

• Temperature of the NO

2

: Increasing the temperature of the permeation tube

increases the pressure inside the tube and therefore increases the rate of

permeation.