Instrument maintenance, Maintenance schedule – Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 159

Model 9110E Instruction Manual

Instrument Maintenance

M9110E Rev B

145

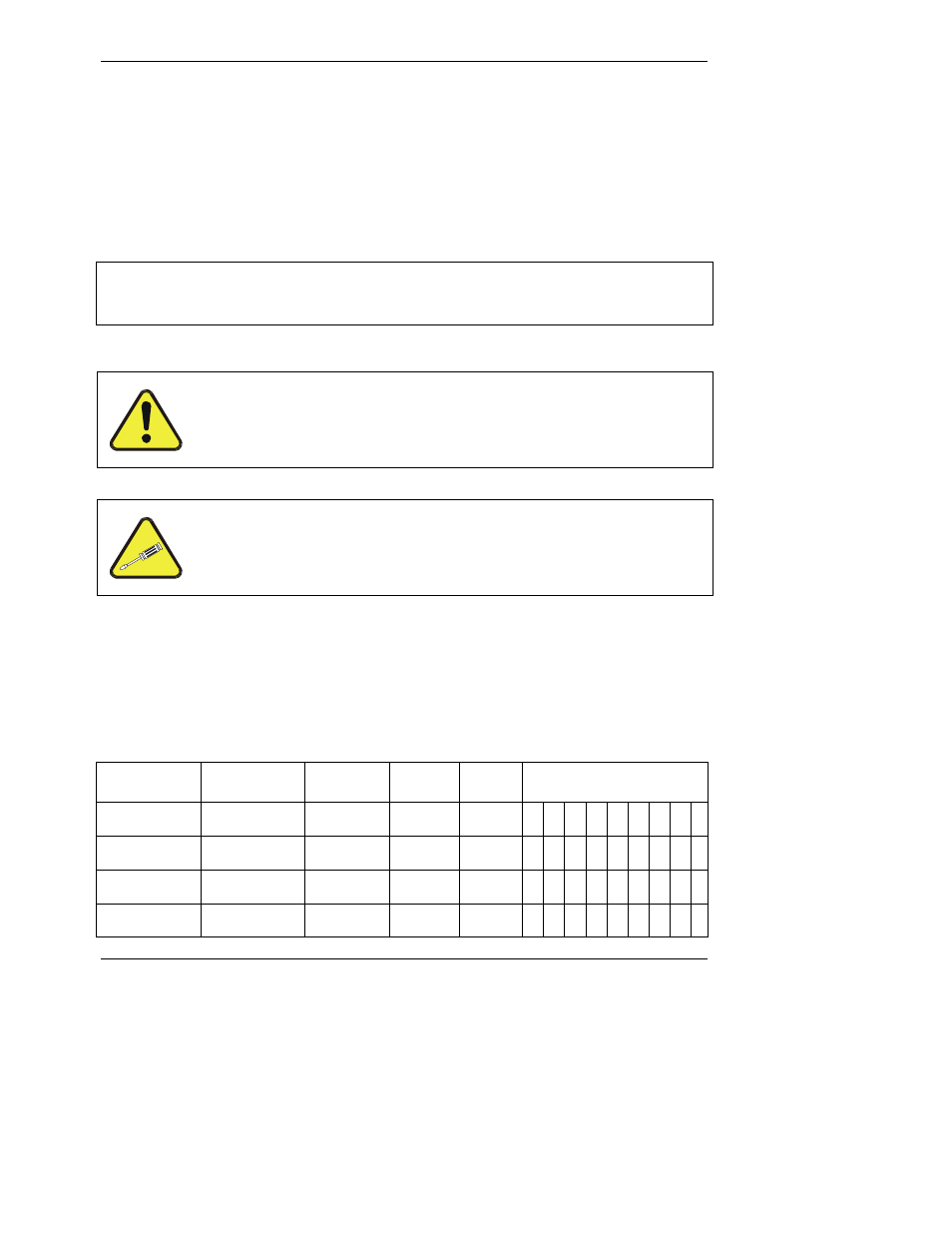

9. INSTRUMENT MAINTENANCE

Predictive diagnostic functions including data acquisition, failure warnings and alarms built

into the analyzer allow the user to determine when repairs are necessary without perform-

ing unnecessary, preventative maintenance procedures. There is, however, a minimal

number of simple procedures that, when performed regularly, will ensure that the analyzer

continues to operate accurately and reliably over its lifetime. Repair and troubleshooting

procedures are covered in Chapter 11 of this manual.

NOTE

A span and zero calibration check must be performed following some of the

maintenance procedures listed below. Refer to Chapter 7.

CAUTION

Risk of electrical shock. Disconnect power before performing any

operations that require entry into the interior of the analyzer.

NOTE

The operations outlined in this chapter must be performed by

qualified maintenance personnel only.

9.1. Maintenance Schedule

Table 9-1 is the recommended maintenance schedule for the M9110E. Please note that in

certain environments with high levels of dust, humidity or pollutant levels some

maintenance procedures may need to be performed more often than shown.

Table 9-1: M9110E Preventive Maintenance Schedule

Item Action

Frequency

Cal

Check ?

Manual

Section

Date Performed

TEST functions Review and

evaluate

Weekly No

Table

A-

3

Particulate

filter

Change

particle filter

Weekly

No 9.3.1

Zero/span

check

Evaluate offset

and slope

Weekly

Yes 7.3,

7.6

Zero/span

calibration

Zero and span

calibration

Every 3

months

Yes 7.2,

7.4, 7.5

Table 9-1:

M9110E Preventive Maintenance Schedule (continued)