Predictive diagnostics, Maintenance procedures – Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 161

Model 9110E Instruction Manual

Instrument Maintenance

M9110E Rev B

147

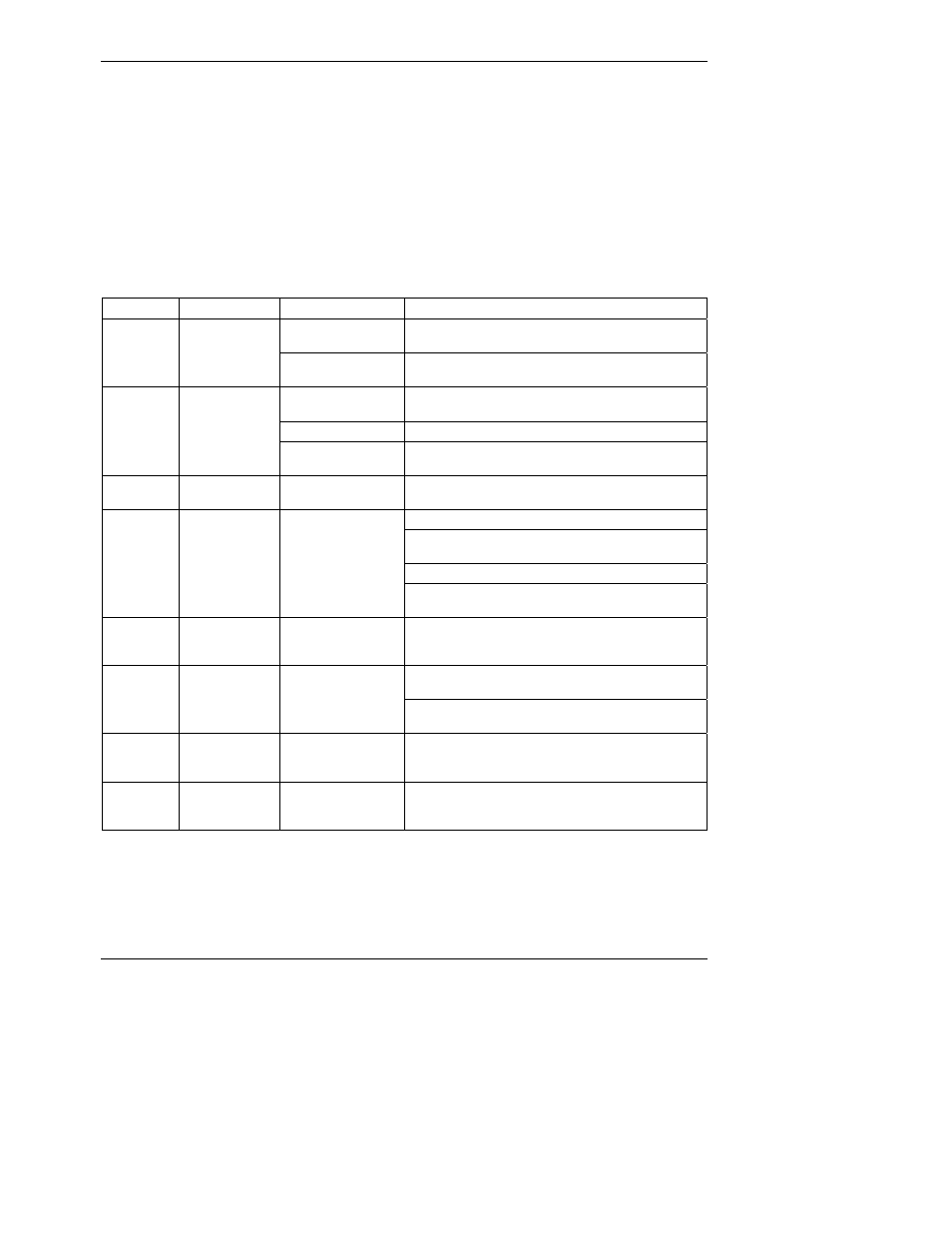

9.2. Predictive Diagnostics

The analyzer’s test functions can be used to predict failures by looking at trends in their

values. Initially it may be useful to compare the state of these test functions to the values

measured on your instrument at the factory and recorded on the M9110E Final Test and

Validation Data Form

(TAI part number 04490, attached to the manual). Table 9-2 can be

used as a basis for taking action as these values change with time. The internal data

acquisition system (iDAS) is a convenient way to record and track these changes. APICOM

control software can be used to download and review these data even from remote

locations (Section 6.11.5 describes APICOM).

Table 9-2: Predictive Uses for Test Functions

Function Expected

Actual

Interpretation & Action

Fluctuating

Developing leak in pneumatic system. Check for

leaks

RCEL

pressure

Constant to

within ± 0.5

Slowly increasing

Pump performance is degrading. Replace pump

head when pressure is above 10 in-Hg-A

Fluctuating

Developing leak in pneumatic system. Check for

leaks

Slowly increasing

Flow path is clogging up. Replace orifice filters

SAMPLE

pressure

Constant

within

atmospheric

changes

Slowly decreasing

Developing leak in pneumatic system to vacuum

(developing valve failure). Check for leaks

Ozone

Flow

Constant to

within ± 15

Slowly decreasing

Flow path is clogging up. Replace orifice filters

Developing AZERO valve failure. Replace valve

PMT cooler failure. Check cooler, circuit, and

power supplies

Developing light leak. Leak check.

AZERO

Constant

within ±20 of

check-out

value

Significantly

increasing

O

3

air filter cartridge is exhausted. Change

chemical

NO2

CONC

Constant for

constant

concentrations

Slowly decreasing

signal for same

concentration

Converter efficiency may be degrading. Replace

converter.

Change in instrument response. Low level

(hardware) calibrate the sensor

NO2

CONC

(IZS)

Constant

response from

day to day

Decreasing over

time

Degradation of IZS permeation tube. Change

permeation tube

NO2

CONC

(IZS)

Constant

response from

day to day

Heavily fluctuating

from day to day

Ambient changes in moisture are affecting the

performance. Add a dryer to the zero air inlet.

NO CONC

Constant for

constant

concentration

Decreasing over

time

Drift of instrument response; clean RCEL

window, change O

3

air filter chemical.

9.3. Maintenance Procedures

The following procedures need to be performed regularly as part of the standard

maintenance of the Model 9110E.