Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 188

Theory of Operation

Model 9110E Instruction Manual

174

M9110E Rev B

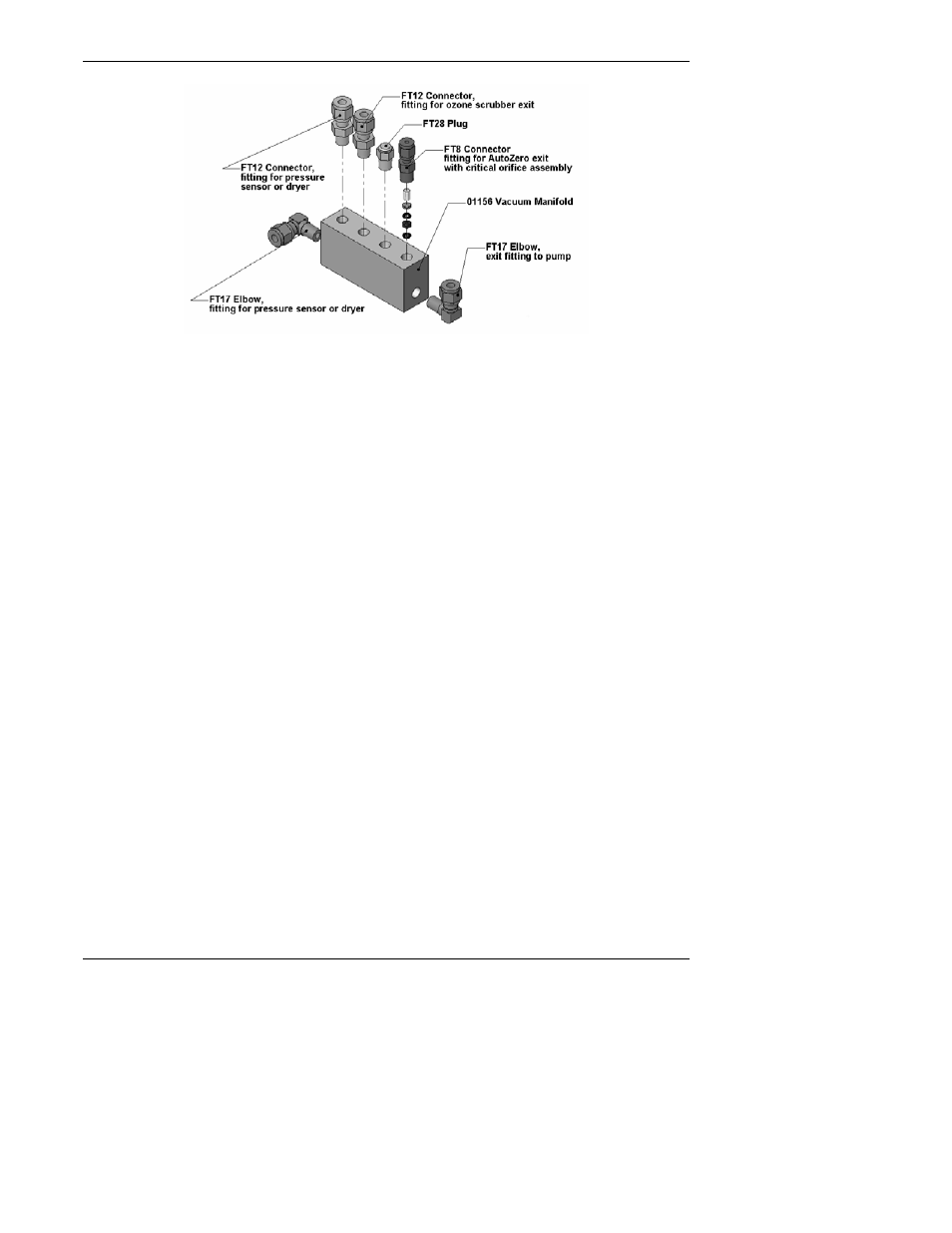

Figure 10-10:

Vacuum Manifold, Standard Configuration

10.2.10.2. Sample Pressure Sensor

An absolute pressure transducer connected to the input of the NO/NO

X

valve is used to

measure the pressure of the sample gas before it enters the analyzer’s reaction cell. This is

the “upstream” pressure mentioned above, which is used to compute sample flow rate. In

conjunction with the vacuum pressure sensor, it is also used to validate the critical flow

condition (2:1 pressure ratio) through the sample gas critical flow orifice (Section 10.2.9).

If the temperature/pressure compensation (TPC) feature is turned on (Section 10.4.3), the

output of this sensor is also used to supply pressure data for that calculation.

The actual pressure value is viewable through the analyzer’s front panel display as the test

function SAMP. The flow rate of the sample gas is displayed as SAMP FLW..

10.2.10.3. Vacuum Pressure Sensor

An absolute pressure transducer connected to the exhaust manifold is used to measure the

pressure downstream from and inside the instrument’s reaction cell. The output of the

sensor is used by the CPU to calculate the pressure differential between the gas upstream

of the reaction cell and the gas downstream from it and is also used as the main diagnostic

for proper pump operation. If the ratio between the upstream pressure and the downstream

pressure falls below 2:1, a warning message (SAMPLE FLOW WARN) is displayed on the

analyzer’s front panel (Section 6.2.2) and the sample flow rate will display XXXX instead of

an actual value. If this pressure exceeds 10 in-Hg-A, an RCEL Pressure Warning is

issued, even though the analyzer will continue to calculate a sample flow up to ~14 in Hg.

Also, if the temperature/pressure compensation (TPC) feature is turned on (Section 10.4.3),

the output of this sensor is used to supply pressure data for that calculation. This meas-

urement is viewable through the analyzer’s front panel as the test function RCEL.

10.2.10.4. O

3

Supply Air Flow Sensor

A mass flow meter connected between the Perma Pure

®

dryer and the O

3

generator

measures the flow rate of O

3

supply air through the analyzer. This information is used to

validate the O

3

gas flow rate. If the flow rate exceeds ±15% of the nominal flow rate (80