Gas flow problems – Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 213

Model 9110E Instruction Manual

Troubleshooting & Repair

M9110E Rev B

199

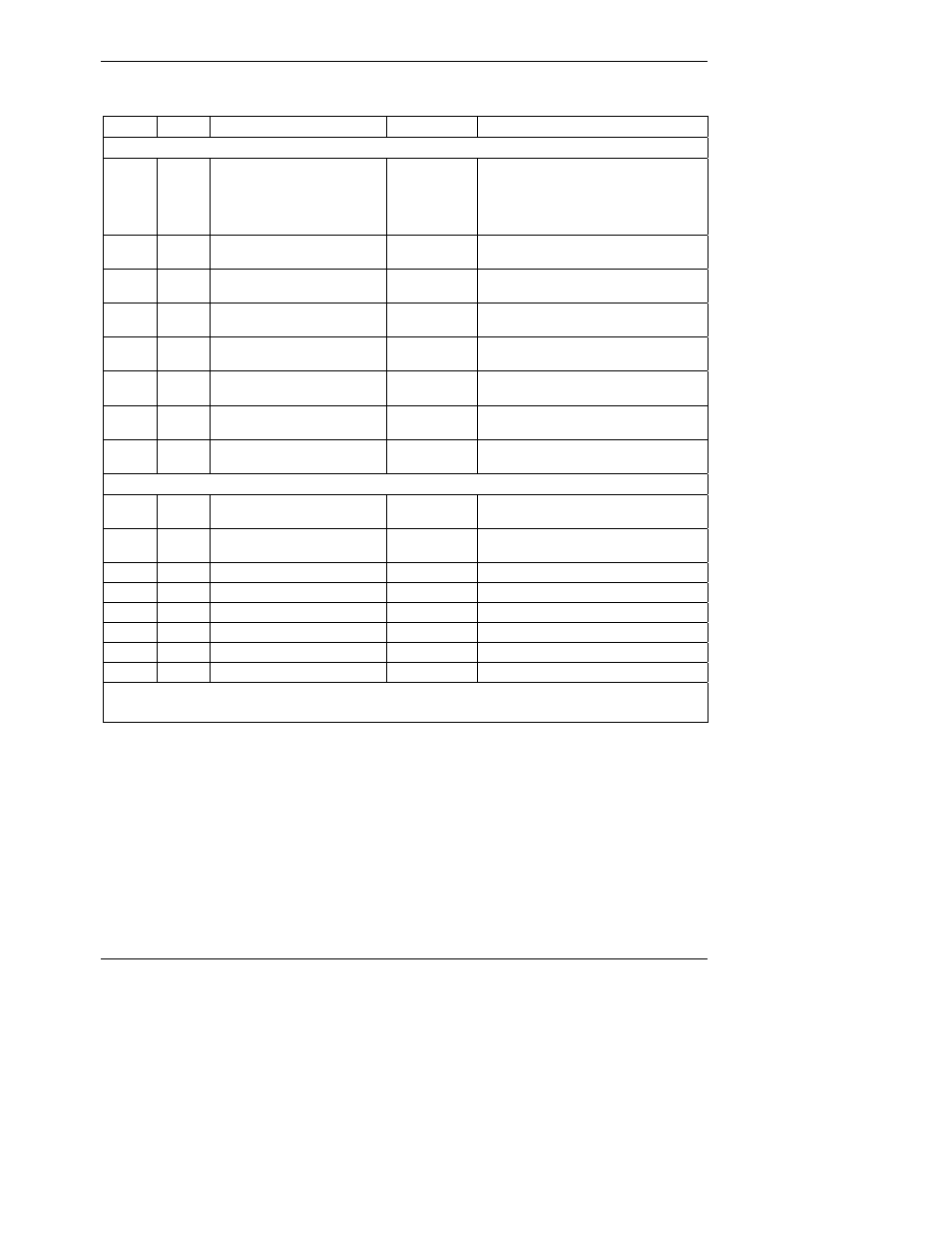

Table 11-2: Relay Board Status LEDs

LED

Color

Function

Fault Status

Indicated Failure(s)

LED Row 1 (center of board)

D1

red

Watchdog Circuit; I

2

C bus

operation.

Continuously

ON or OFF

Failed or halted CPU; faulty

motherboard, keyboard, relay

board; wiring between mother-

board, keyboard or relay board; +5

V power supply

D2

yellow Relay 0 - reaction cell

heater

Continuously

ON or OFF

Heater broken, thermistor broken

D3

yellow Relay 1 - NO

2

converter

heater

Continuously

ON or OFF

Heater broken, thermocouple

broken

D4

1

yellow Relay 2 - manifold heater

Continuously

ON or OFF

Heater broken, thermistor broken

D7

2

green

Valve 0 - zero/span valve

status

Continuously

ON or OFF

Valve broken or stuck, valve driver

chip broken

D8

2

green

Valve 1 - sample/cal valve

status

Continuously

ON or OFF

Valve broken or stuck, valve driver

chip broken

D9

green

Valve 2 - auto-zero valve

status

Continuously

ON or OFF

Valve broken or stuck, valve driver

chip broken

D10

green

Valve 3 - NO/NO

x

valve

status

Continuously

ON or OFF

Valve broken or stuck, valve driver

chip broken

LED Row 2 (top of board)

D5

yellow Relay 3 - IZS heater

Continuously

ON or OFF

Heater broken, thermistor broken

D6

yellow Relay 4 – (O

2

sensor heater

9110EH/EM)

N/A N/A

D11

green

Valve 4 – Spare

N/A

N/A

D12

green

Valve 5 – Spare

N/A

N/A

D13

green

Valve 6 – Spare

N/A

N/A

D14

green

Valve 7 – Spare

N/A

N/A

D15 green

Mosfet1/DC

driver-Unused

N/A

N/A

D16 green

Mosfet2/DC

driver

-Unused

N/A

N/A

1

Special configurations only

2

Only active for instruments with Z/S valve or IZS options installed

11.2. Gas Flow Problems

The M9110E has two main flow paths, the sample flow and the flow of the ozone supply air.

With IZS or zero/span valve option installed, there is a third (zero air) and a fourth (span

gas) flow path, but either one of those is only controlled by critical flow orifices and not

displayed on the front panel or stored to the iDAS. The full flow diagrams of the standard

configuration and with options installed (Appendix D, document 04574) help in trouble-

shooting flow problems. In general, flow problems can be divided into three categories:

• Flow is too high

• Flow is greater than zero, but is too low, and/or unstable

• Flow is zero (no flow)