Sample particulate filter – Teledyne 9110E - Nitrogen Oxides Analyzer User Manual

Page 181

Model 9110E Instruction Manual

Theory of Operation

M9110E Rev B

167

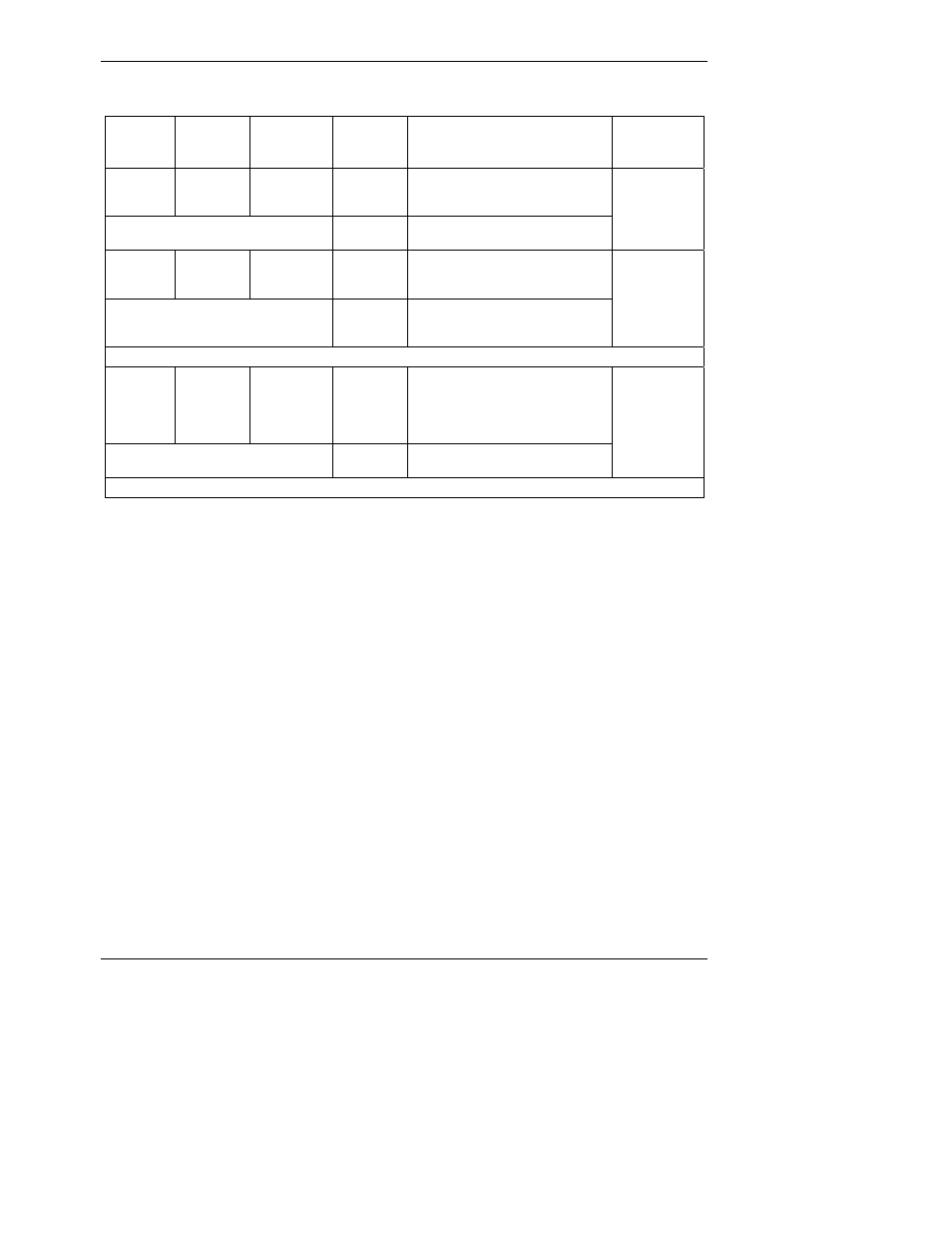

Table 10-2: M9110E Valve Cycle Phases

Phase

NO/ NO

X

Valve

Status

Autozero

Valve

Status

Time

Index

Activity Figure

NO

Measure

Open to

AutoZero

valve

Open to

reaction

cell

0 - 2 s

Wait period (NO dwell time).

Ensures reaction cell has been

flushed of previous gas.

2 - 4 s

Analyzer measures chemilumi-

nescence in reaction cell.

Figure 10-2

NO

X

Measure

Open to

NO

2

converter

Open to

reaction

cell

4 – 6 s

Wait period (NO

X

dwell time).

Ensures reaction cell has been

flushed of previous gas.

6 – 8 s

Analyzer measures NO + O

3

chemiluminescence in reaction

cell.

Figure 10-2

Cycle repeats every ~8 seconds

AutoZero Open

to

AutoZero

valve

Open to

vacuum

manifold

0 – 4 s

Wait period (AZERO dwell time).

Ensures reaction cell has been

flushed of sample gas and

chemiluminescence reaction is

stopped.

4 - 6 s

Analyzer measures background

noise without sample gas

Figure 10-4

Cycle repeats every minute

The M9110E uses a 0.010” (10 mil) diameter orifice to achieve a flow rate of about

450-500 cm³/min. With nominal pressures of 28 and 4 in-Hg-A for the sample and reaction

cell pressures, respectively. The necessary ratio of sample to reaction cell pressure of 2:1 is

largely exceeded and accommodates a wide range of possible variability in atmospheric

pressure and pump degradation. Once the pump degrades and vacuum pressure exceeds

14 in-Hg-A, the ratio between sample and vacuum pressures is less than 2:1 and, hence, a

critical flow rate can no longer be calculated. At this point, the instrument will display an

invalid sample flow rate measurement (XXXX).

For the routing of the sample gas flow, the analyzer uses a variety of valves. The NO/NO

X

valve directs the sample gas either directly to the reaction cell or through the unit’s NO

2

converter, alternating every ~4 s. The AutoZero valve directs the sample gas stream to

completely bypass the reaction cell for dark noise measurement once every minute, which

is then subtracted as a measurement offset from the raw concentration signal. The valve

cycle phases are summarized in Table 10-2.

10.2.3. Sample Particulate Filter

To remove particles in the sample gas, the analyzer is equipped with a PTFE membrane

filter of 47 mm diameter (also referred to as the sample filter) with a 1 µm pore size. The

filter is accessible through the front panel, which folds down (after removal of the CE Mark

safety screw), and should be changed according to the maintenance schedule in Table 9-1.