Paper winder application example – Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 273

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

273

Motor Control

Chapter 4

Empirically setting values P314 [SLAT Err Stpt] and P315 [SLAT Dwell Time]

other than default may help create even smoother transitions.

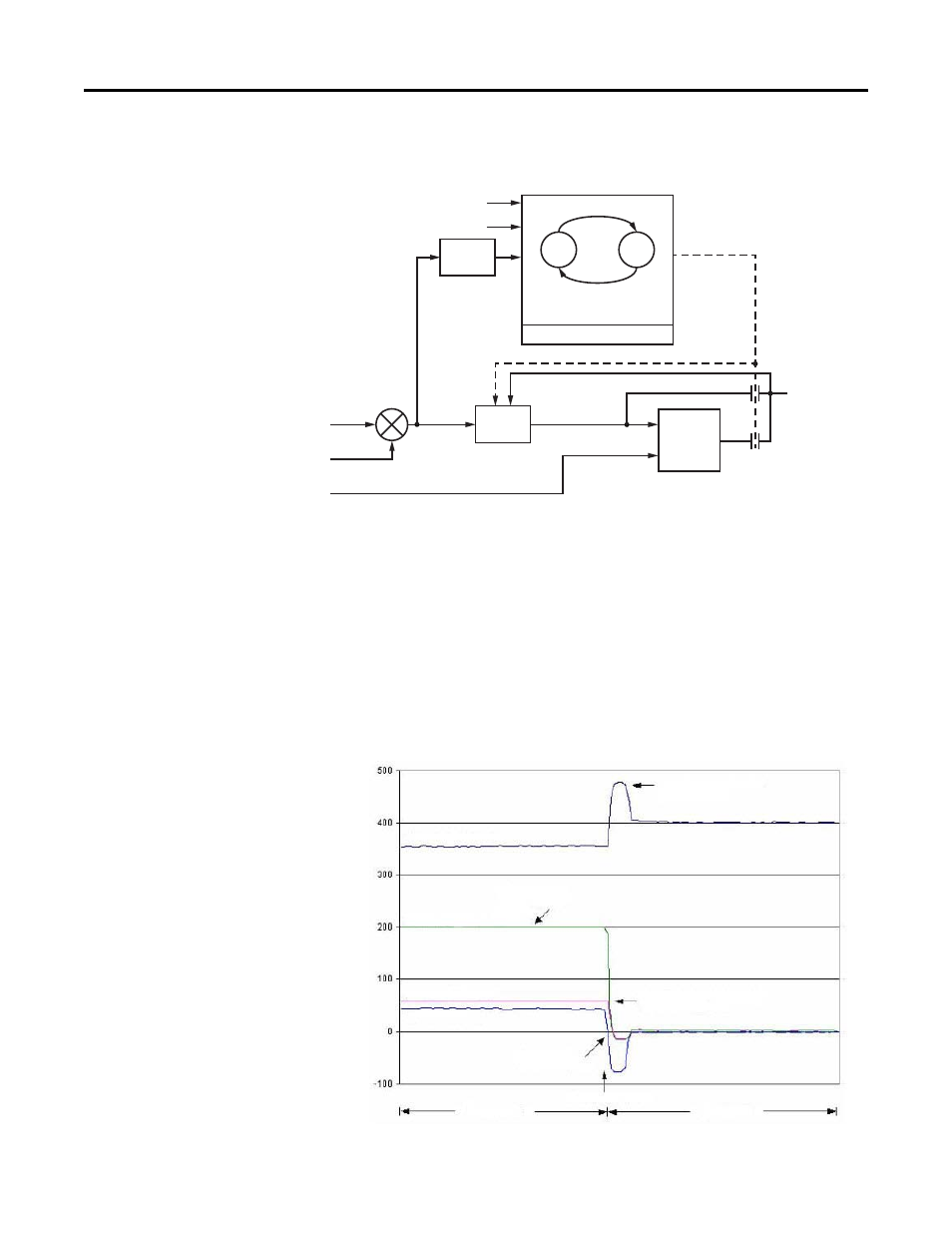

Paper Winder Application Example

The drive is set for SLAT Minimum mode, so that the drive normally runs in

Torque mode and follows P675 [Trq Ref A Sel]. [Trq Ref A Sel] comes from an

external controller and is approximately 60% of motor torque during the

snapshot (shown below). The speed reference, also from an external controller, is

set just above the speed feedback to saturate the speed regulator while in Torque

mode. The following snapshot captures what occurs in the drive during a break in

the web.

Figure 34 - SLAT Min to Forced Speed Mode

+

–

P314 [SLAT Err Stpt]

P315 [SLAT Dwell Time]

Low Pass

Filter

Speed Error < 0

Off

On

Speed Error > SLAT Setpoint

for SLAT Time

FSM State Controller

Application Dependant

Speed Reference Bias

Motor Speed Feedback

External Torque

Reference (ETR)

Speed Error

Speed Regulator

Output (SRO)

Forced Speed

Mode (FSM)

FSM - On

Off

PI

Regulator

Min

Select

Internal Torque

Reference (ITR)

Small amount of overshoot

during web break.

Motor Speed Feedback (RPM)

Speed Regulator Out (%)

Speed Regulator Saturated

Motor Torque Reference (%)

Speed Error (RPM)

Speed Regulator is preloaded with

Motor Torque Reference.

Speed Error becomes negative.

Web break occurs.

Torque Mode

Speed Mode