Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 211

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

211

Motor Control

Chapter 4

Step 5 – Determine the Minimum Resistance

Each chopper module in the table above has a minimum resistance associated

with it. If a resistance lower than the value show in the table is connected to the

chopper module, the brake transistor is most likely be damaged.

Step 6 – Choosing the Dynamic Brake Resistance Value

To avoid damage to this transistor and get the desired braking performance, select

a resistor with a resistance between the maximum resistance calculated in Step 3

and the minimum resistance of the selected chopper module.

Step 7 – Estimating the Minimum Wattage requirements for the Dynamic

Brake Resistor

It is assumed that the application exhibits a periodic function of acceleration and

deceleration. If (t

3

- t

2

) = the time in seconds necessary for deceleration from

rated speed to 0 speed, and t

4

is the time in seconds before the process repeats

itself, then the average duty cycle is (t

3

- t

2

)/t

4

. The power as a function of time is

a linearly decreasing function from a value equal to the peak regenerative power

to 0 after (t

3

- t

2

) seconds have elapsed. The average power regenerated over the

interval of (t

3

- t

2

) seconds is Pb/2. The average power in watts regenerated over

the period t

4

is:

P

av

= average dynamic brake resistor dissipation, watts

t

3

- t

2

= Elapsed time to decelerate from rated speed to 0 speed, seconds

t

4

= Total cycle time or period of process, seconds

P

b

= Peak braking power, watts

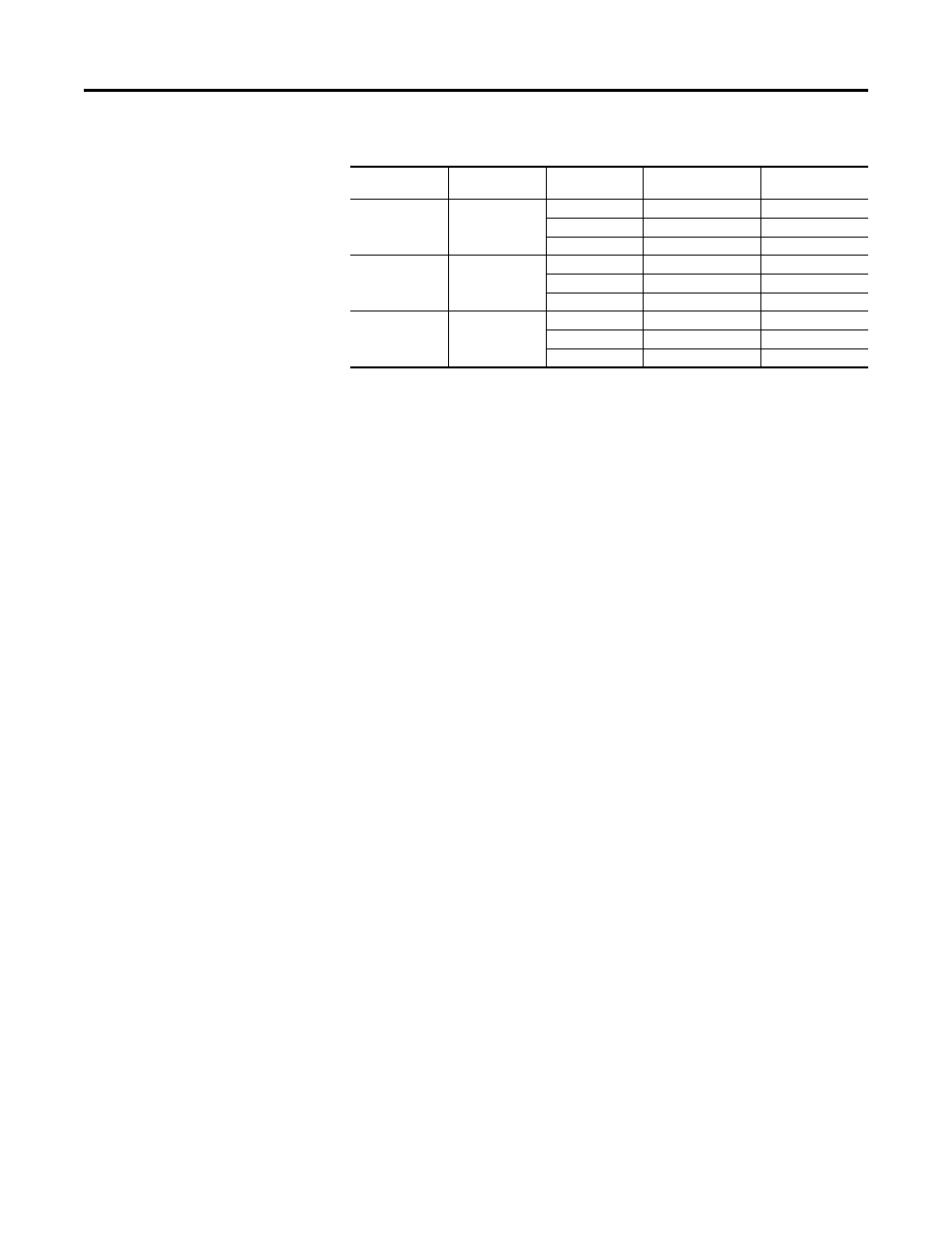

Drive Voltage

(Volts AC)

Turn-On Voltage

(Volts DC)

Cat. No.

Peak Transistor Current

Rating (Amps)

Minimum DB Resistor

Value (Ohms)

230

375

WA018

50

9.0

WA070

200

2.3

WA115

400

1.25

460

750

WB009

25

37

WB035

100

9.0

WB110

400

2.5

575

935

WC009

25

46

WC035

75

15.5

WC085

400

3.0

P

av

t

3

t

2

–

(

)

t

4

------------------

P

b

2

------

Ч

=