Ramp to hold – Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 100

100

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Chapter 1

Drive Configuration

Ramp to Hold

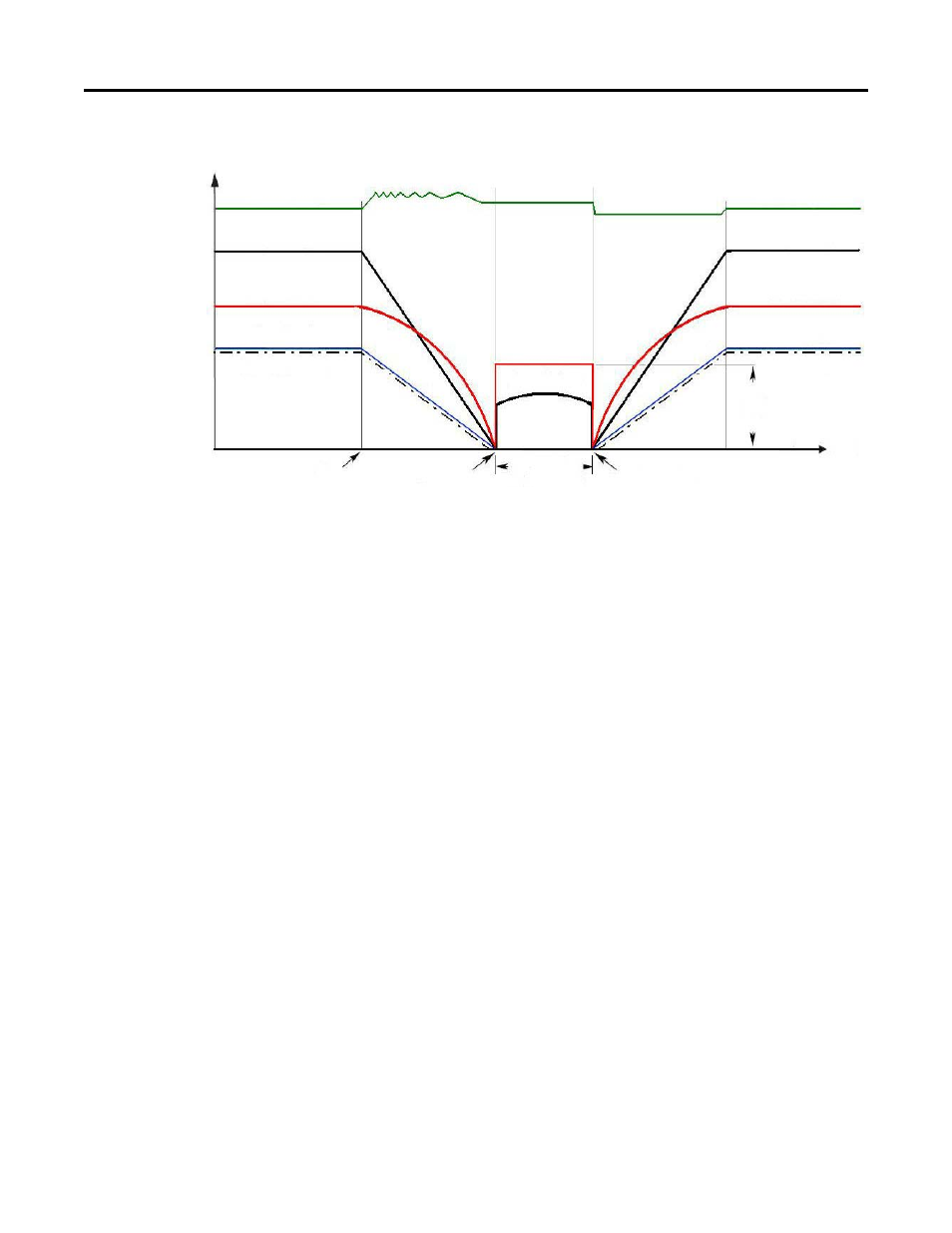

This method combines two of the methods above. It uses drive output reduction

to stop the Load and DC injection to hold the load at zero speed once it has

stopped:

•

On Stop, drive output decreases according to the programmed pattern

from its present value to zero. The pattern can be linear or squared. The

output decreases to zero at the rate determined by the programmed P37

[Maximum Freq] and the programmed active P537/538 [Decel Time 1/2]

•

The reduction in output can be limited by other drive factors such as bus

or current regulation.

•

When the output reaches zero 3 phase drive output goes to zero (off ) and

the drive outputs DC voltage on the last used phase to provide the current

level programmed in P394 [DC Brake Level]. This voltage causes a

holding brake torque.

•

DC voltage to the motor continues until a Start command is reissued or

the drive is disabled.

•

If a Start command is reissued, DC Braking ceases and the drive returns to

normal AC operation. If an Enable command is removed, the drive enters a

Not Ready state until the enable is restored.

Bus Voltage

Output Voltage

Output Current

Motor Speed

Command Speed

Time

DC Hold for

indeterminate

amount of time.

Stop Command

Zero Command Speed

Output Voltage

Output Current

DC

Hold

Level

Bus Voltage

Output Voltage

Output Current

Motor Speed

Command Speed

Start Command