Shear pin time, Fault indication, Application example – Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 189

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

189

Diagnostics and Protection

Chapter 3

Shear Pin Time

If an immediate action is to be taken, set shear pin time to 0. If the shear pin level

is to be ignored for a period of time, enter that value into P437 [Shear Pin 1

Time] or P440 [Shear Pin 2 Time].

Generally, some value greater than 0 is entered in shear pin time to eliminate any

faults on very short peak current spikes. Thus eliminating nuisance tripping.

Fault Indication

A unique fault (Shear Pin 1, F61) or (Shear Pin 1, F62) is generated if the

function is activated and the condition occurs.

Application Example

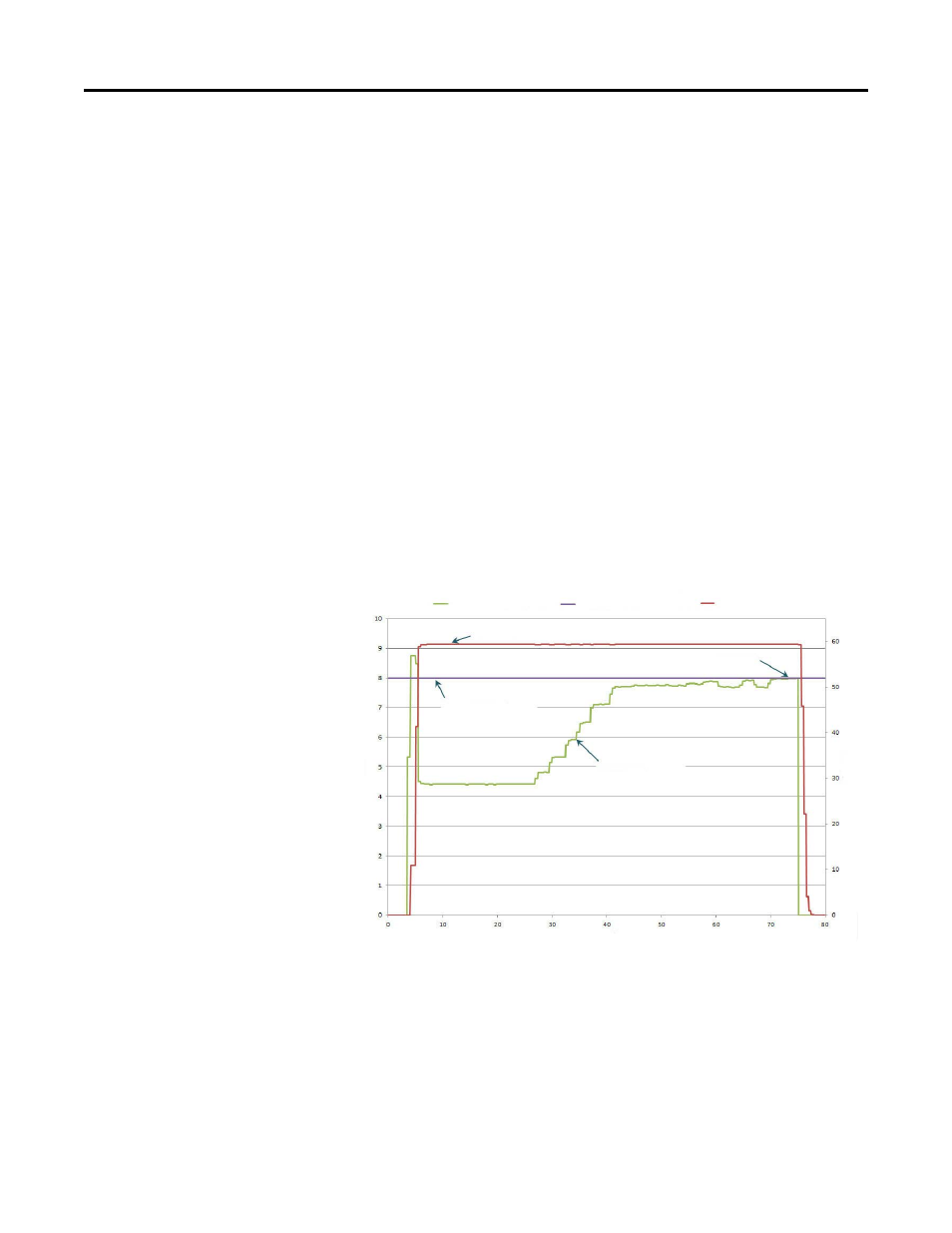

By programming the Shear Pin feature, the drive faults, stopping the excess

torque before mechanical damage occurs.

Shear Pin - Gradual Loading

P7 [Output Current]

P436 [Shear Pin1 Level]

P3 [Mtr Vel Fdbk]

Motor Speed

Shear Point 1 Level

Increasing Load

Drive Faults

Seconds

Amps

Fre

qu

en

cy