Carrier (pwm) frequency – Rockwell Automation 20G PowerFlex 750-Series AC Drives User Manual

Page 196

196

Rockwell Automation Publication 750-RM002B-EN-P - September 2013

Chapter 4

Motor Control

Carrier (PWM) Frequency

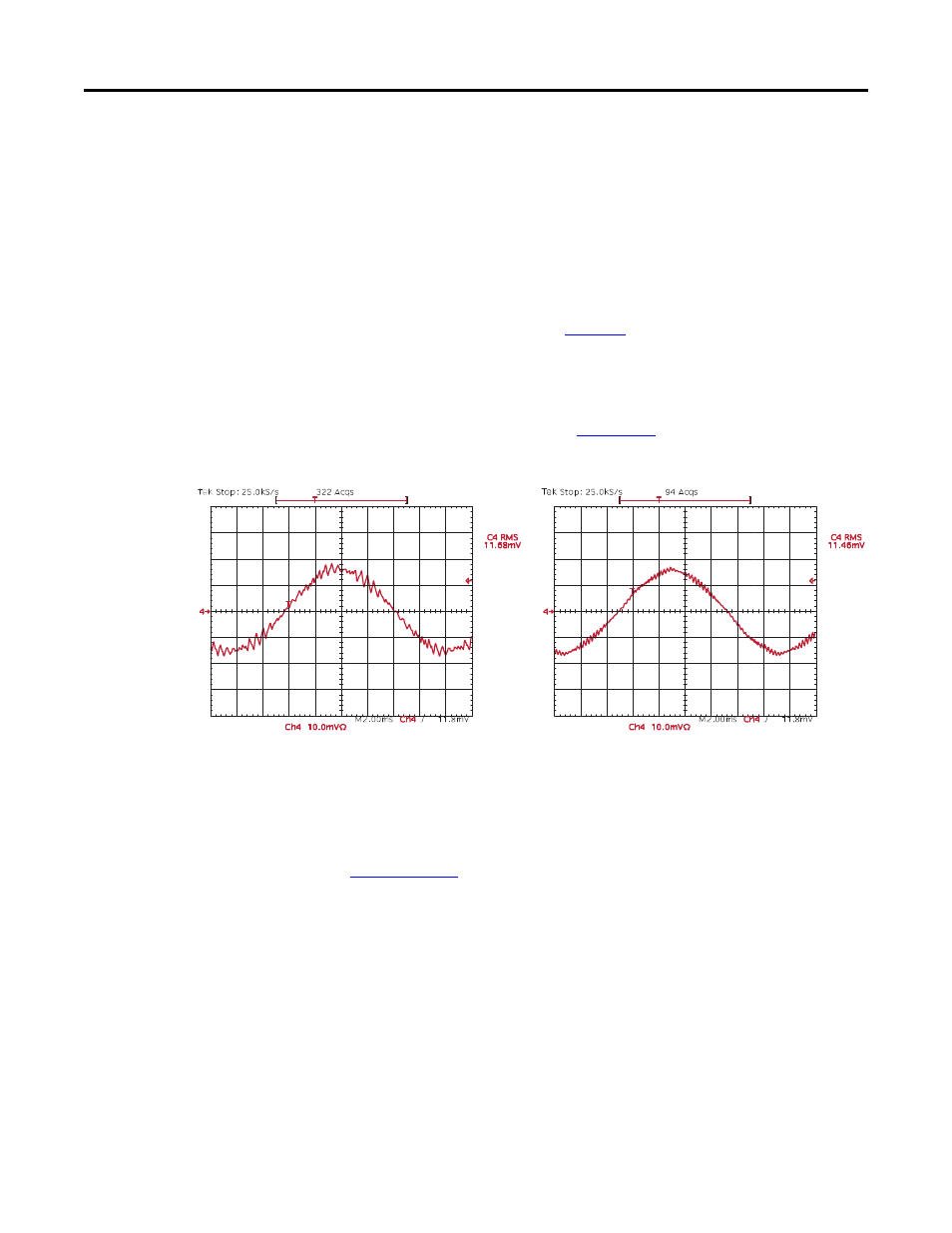

P38 [PWM Frequency] sets the carrier frequency at which the inverter output

IGBTs (Insulated Gate Bipolar Transistors) switch. In general, use the lowest

possible switching frequency that is acceptable for the particular application. An

increased carrier frequency causes less motor heating and lowers the audible noise

from the motor. However, it causes the IGBTs to heat up faster than by using the

factory default PWM frequency of 4 kHz or 2 kHz depending on drive’s the

frame size. The higher switching frequency smoothes the current waveform. This

reduces vibration in the motor windings and laminations reducing audible noise.

This is desirable in applications where motors are installed close to control rooms

or in domestic environments. See

and note the output current at 2 kHz

and 4 kHz. The smoothing of the current waveform continues 12 kHz.

The maximum carrier frequency per frame size and the derating guidelines

according to PWM frequency can be found in the PowerFlex 750-Series AC

Drives Technical Data, publication

.

Figure 21 - Current at 2 kHz and 4 kHz PWM Frequency

Some undesirable effects of higher switching frequencies include higher cable

charging currents, higher potential for common mode noise and an increased risk

of motor winding insulation breakdown due to the reflected wave phenomenon.

Refer to the Wiring and Grounding Guidelines for PWM Drives, publication

for further information. A very large majority of all drive

applications will perform adequately at 2 kHz or 4 kHz.

Some applications require a fixed minimum PWM frequency (that is, using a sine

wave filter in the output of the drive). In this case, P40 [Mtr Options Cfg] Bit 9

“PWM FreqLock” should be set to prevent the drive from lowering its carrier

frequency due to a drive overload condition.

2 kHz

4 kHz